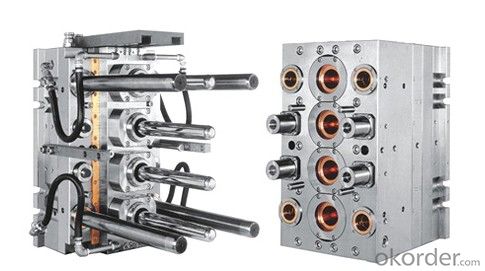

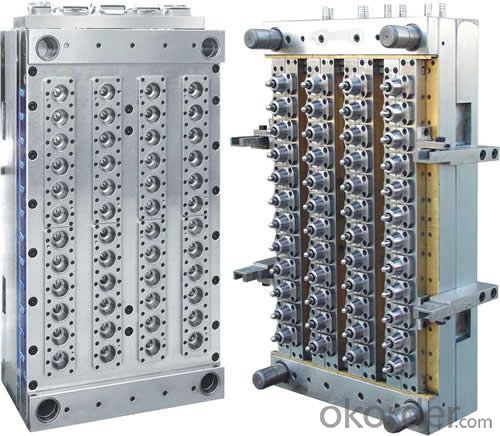

PET Mould and Parts with Hot Runner System Professinal Preform

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PET Mould and Parts with Hot Runner System Professinal Preform

pecifications

Mould steel : DIN 2316,S136

Product material:steel

size:customized

Process:injection molding

Colour:as customer's requirements

| Mould Base | LKM,HASCO,DME |

| Cavity/core material | 2738,2343,S130,2344,718,8407,S136,P20,KD-61,NAK80,H13 ect |

| Cavity QTY | Single-cavity/Muti-cavity |

| Runner | Yudo cold/hot runner |

| Gate | Submarie gate,side/edge gate |

| Mould lifetime | 500,000 shots |

| Plastic part material | PC,PA,ABS,PVC,PA66+GF,TPE,SAN,POM.etc |

| Lead time | 20-40days based on different products |

| Package | Wooden cases or cartons |

| Port | Shenzhen |

| Design sofeware | UG/CAD/PROE |

Our Services

1. Can supply with both Mold & Molded parts

2. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

3. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

4. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

5. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

6. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

Product Description

Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

Quality: | ROSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

Surface Finish: | Texture (MT standard), high gloss polishing |

Finish: | Mirror finish etc. |

Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Package: | Standard exported wooden box packed, fumigation process (upon required) |

Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

Annual production: | 250 sets of mold |

- Q: What is the cooling system of the mold

- According to the product shape, people in different templates design with cold water or hot water in and out of the loop, especially near the mold core, cavity and port more requires constant cooling. In a working cycle, the molds have a large cooling area and need to be cooled for a long time, about 80% of a cycle. The design of cooling system should consider the following factors: mould steel variety, length of cooling channel, melt temperature of injection materials and solidification temperature. It should also consider temperature control device, cooling medium flow condition and pressure. The cooling system is designed according to the heat that the mould absorbs heat and the cooling water pipes. Studies have shown that a good cooling design reduces cooling time by about 20 percent.

- Q: What is the role of the grooves in the guide column

- The lubrication oil groove of the guide and guide on the mould is on the guide sleeve, the die is lubricated by the oil gun to the guide and the guide sleeve, and prevents the death from biting.

- Q: How to choose the injection molding machine when the mould design

- If you choose me as a manufacturer of injection molding machines, we will do our best to help you design the equipment you want

- Q: The characteristics of cold making die steel

- It is widely available in cold steel: high hardness, high wear-resisting, high compressive strength and quenching performance Cold stamping die, stamping die, drawing die, extrusion die and so on

- Q: The role of cryogenic processing of die material

- Deep cold will change some mechanical properties, and the main effect will be as follows: Enhance the hardness and strength of the workpiece Ensure the precision of the workpiece Improve the wear resistance of the workpiece Improve the impact toughness of the workpiece Improve the internal stress distribution of the workpiece and increase the fatigue strength Improve the corrosion resistance of the workpiece.

- Q: Is the digital control the same as the mold? If not, what's the difference?

- There is a difference, the numerical control is a kind of lathe! The mold is a large scale model! They're very different

- Q: What is the difference between a large water inlet and a thin nozzle?

- The difference between a large water inlet and a thin water nozzle: 1, from the entrance of the entrance to the glue mouth: one is the point gate (directly from the product to the glue) usually called the thin nozzle mold; One is from the side into the glue, gate is relatively big usually call gate mould (but sometimes think products turn into the glue need will do fine shuikou gate into the glue, structure and three board mould) Different from the structure of the mould: the two plates are usually called the large water port molds. There are two kinds of thin water mouth mould and thin water mouth mould.

- Q: What do you mean by the side of the plastic mould

- When the mold is in place, the main view can see the top of the board.I hope my answer will help you.

- Q: How to open the exhaust in the plastic mould exhaust, should notice what?

- The exhaust of plastic mould should be noted Don't be too stressed out Don't overheat the plastic Don't inject too quickly Don't give the piston back too early The weight of the plastic parts should be near the device's rating

- Q: How do you handle the die holder

- Mold clamp mouth usually refers to the Parting surface, Parting line or the Parting line), including the slider, inserts, lifter and so on between the two in the products with line. Note: CNC processing aspect: parting surface machining with rubber products, at the same time to the mold clamp mouth do protection processing, die fillet directly in the machining process can be avoided; To remove the electrode: the separation of the Angle electrode and the electrode of the product is removed and the Angle of the die is avoided in the EDM process. Mold, industrial production to be used for injection molding, blow molding, extrusion, die-casting or forging, metallurgy, stamping, etc., to get the various mold and tools of the desired product. In short, the mold is a tool for molding objects, which are made up of various parts, and different parts are made of different parts. It mainly USES the physical state of the forming material to realize the processing of the physical appearance. There is the title of "mother of industry"

Send your message to us

PET Mould and Parts with Hot Runner System Professinal Preform

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches