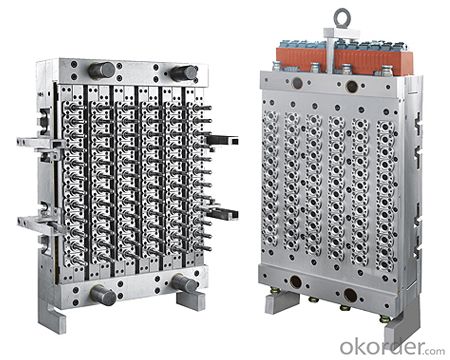

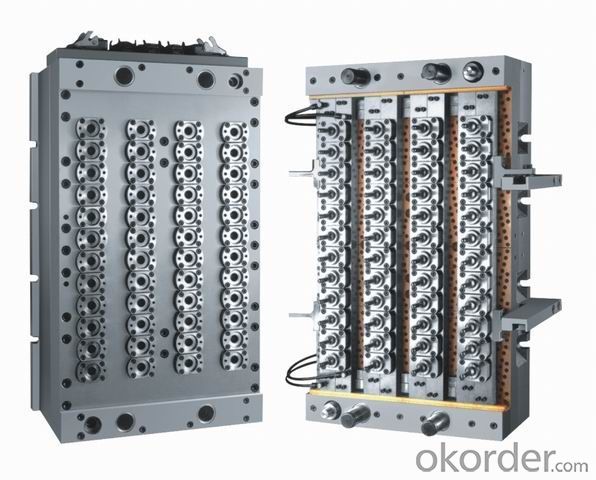

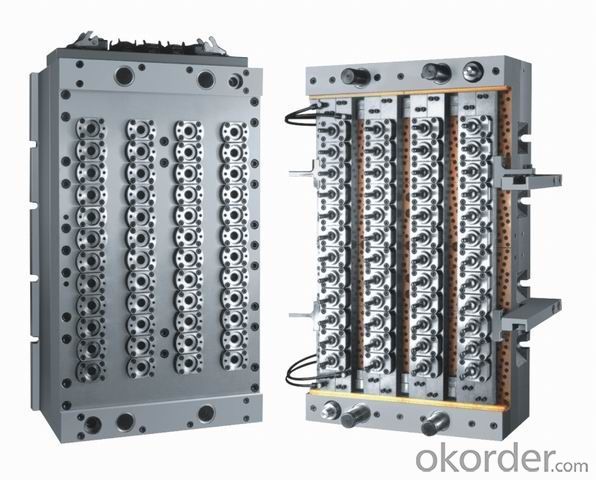

Multi-Cavities PP Preform Mould with Hot Runner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Multi-Cavities PP Preform Mould

The mould is made of high quality steel; the hot runner adopts needle valve balance type plastic feeding; the temperature control system adopts PID single-cavity independent control, so it has very little temperature error and has short molding period; the product has beautiful appearance and very small size error and very high qualification ratio.

2. Main Features of Multi-Cavities PP Preform Mould

| mould specs | Mould Dimension (L * W * H) |

32-cavity (PET) valve gate preform | 815*610*500550 |

48-cavity (PET) valve gate preform | 1100*610*500550 |

72-cavity (PET) valve gate preform | 1100*850*550650 |

96-cavity (PET) valve gate preform | |

| 128- cavity (PET) valve gate preform |

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

The company can provide full no-man bottle preform product line, which includes injection machine, mould robotic arm and moulds.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: How many kinds of equipment can be used to open the mould?

- Its success or failure depends largely on the design. General tooling development requires common processing equipment, heat treatment equipment, to accommodate the special and uniqueness of the development parts. Nc machine tool, the processing center is also the good practitioner of the open mode; In recent years, special processing equipment, such as electrical erosion, laser, ultrasonic, etc. Are also gradually entering the mould processing area.

- Q: How to choose the injection molding machine when the mould design

- All parameters affecting the molding machine should be taken into consideration: the size of the mould, the amount of glue, the locking force, and the driving distance. Today's injection molding machine is mature. All other parameters can meet the requirements as long as the mold can be molded. All the usual first consideration is to select the injection molding machine according to the shape of the mould. If the mold is special in some way, other parameters are given. For example, if the mold is particularly high, consider whether it is sufficient to open the module. Especially if it's flat, consider whether the lock force is sufficient

- Q: What is the number of holes in the mold?

- There's a couple of products in a mold, and if it's two different products, it's called 1 + 1, and the four holes are 1X4, which means it's 4 identical products

- Q: How many products can a mold make?

- Associated with the material of mould and casting method, had better use a scale of 0-8000 pieces of aluminum mould (ordinary sand casting), 0-13000 pieces (molding machine), plastic mold is bad to use, steel is the most strong, but not suitable for manual operation.

- Q: How is the die in the manufacturing industry

- Mold entry should be separate: If the period of use is over one year, the fixed assets shall be credited, and the depreciation shall be gradually recovered from the period of time. entries Borrowing: fixed assets -- molds Loan: bank deposit/inventory cash/accounts payable 2) use fixed number of year within a year, or easy to loss, recorded in the packing materials and low-value products, you can use the double fifth amortization method (recipients when cancel after verification 50% cost, scrap again when the cost of cancel after verification of the remaining 50%)

- Q: What is the difference between a large water inlet and a thin nozzle?

- The difference between a large water inlet and a thin water nozzle: 1, from the entrance of the entrance to the glue mouth: one is the point gate (directly from the product to the glue) usually called the thin nozzle mold; One is from the side into the glue, gate is relatively big usually call gate mould (but sometimes think products turn into the glue need will do fine shuikou gate into the glue, structure and three board mould) Different from the structure of the mould: the two plates are usually called the large water port molds. There are two kinds of thin water mouth mould and thin water mouth mould.

- Q: Would you please tell me what the difference in the mold Tooling and mold

- To figure out the difference, first of all to its source. Why some get tooling, mold, this is because the mold itself, it does not belong to an industry, he is just a tool production corresponding products, regardless of the quality system, you can pay attention to, die mold is out of place in the formal product, but with the identity of the jig, so called tooling, also can saying is the floorboard of the plastic mold and metal mold. So when is your foreign customers have the size of the company, said its engineers mold most with tooling, mould = mold is a kind of English writing, is a kind of American writing, usually refers to the plastic mold die is the only general hardware mold,

- Q: What is the relation between the mould and the clamp

- How to say, big is all belong to the mechanical industry, say to the relation, I personally think to make the mold to be able to make a fixture, do jig not necessarily can make the mold. The mold needs more experience, and the fixture needs more creative thinking. The common fixture is non-target, but the mold is not the standard, but is roughly the same type. Such as stamping die of blanking die, the structure is basically all the same, just in the middle of the blanking shape, templates, fixed plate, stripper plate up and down, up and down mold core, unloading spring, guide pin guide sleeve is involved. There are many different types of jig, but the key is to locate and clamp these two core ideas. Well, I hope it works for you.

- Q: The core is the moving or the model, male or female?

- Dynamic model is also called the male die, die is also called the master pattern, as far as the core is a dynamic model with fixed mode is not necessarily, just general design core in moving die, it is because we hope that after mold opening mold, plastic pieces on a dynamic model of ejection device, so the general core in moving die.

- Q: In die mold, is it better to use UG or PROE? That's a quick one. Is it convenient?

- If it's a product design it's better to use proe. If you're doing mold design or programming I think it's better to use ug. The ug submodule, which is fast enough to unplug the electrodes, and the ug external technology is very mature, and the unplugged electrode is automated in the way out of the material. Mold design main push UG. There is a high degree of UG promotion. Software updates are fast, and someone might say that software updates are too late. Update quickly indicates that software companies have the money to be able to do so. It's good to learn a version, like 4.0. Although there were 5.0, most of the factory software was not updated, and computer hardware couldn't keep up. The UG mould library is full of information and is commonly used in the dragon card mould library.

Send your message to us

Multi-Cavities PP Preform Mould with Hot Runner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches