PET Preform Plastic Molds Injection PET Moulding Top Level

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

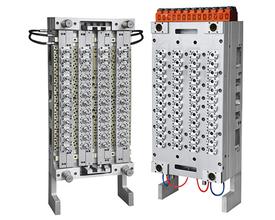

PET Preform Plastic Molds Injection PET Moulding Top Level

he thickness and weight of moulds are in accordance with the tubes,these measurments will change in case the products ar e improved.

Productivity

Fast cycling due to specially designed cooling circuits

Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time

Standard interchangeable mold components,replacement parts available within 24 hours

Reliability

Rugged design for long life

Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers

Roller cams actuate both the opening and closing actions on the thread splits

Part quality

Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes

Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms.

PET Preform Mould Main Components Specification and Advantages | ||

Main component | Specification and Advantages. | |

Core | 2316 steel from Sweden. | high quality special mould steel from sweden (HRC >45) gurantee 2 million shots without any maintenance |

Neck | S136 steel from Sweden, HRC >60, International standard screw neck. | |

Cavity | 2316 steel from Sweden Each cavity have an independent temperature controller. Each cavity self-clamp independently, ensure mould concentricity. 0.05-0.06mm. | |

Body | P20 Steel material from Germany | |

Hot runner plate |

2344 Steel material from Germany

| |

Slider Plate | wear-resistant copper | |

specially designed cooling circuits | Proper design reduce molding cycle time to 15 seconds( with proper water chiller and injection machine) about 3-5 shots per minute | |

Hot runner design | make sure the high quality of preform products. | |

Heater | Anole Germany | |

valve gated design with Automatic drop | each cavity has its independent heating zone and temperature is measured by independent thermocouple.(advantages: easily avoid some problems such as white or draw bench on bottom). Valve gated type without tail reduces labor force. | |

Precessed by high presion CNC machine and numerical control loathe machine | Lowest weight and dimensional variation thickness between max. part and min. part is not more than 0.05mm make sure that every parts can match well.

| |

Our Services

1. Can supply with both Mold & Molded parts

2. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

3. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

4. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

5. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

6. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

Product Description

Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

Quality: | ROSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

Surface Finish: | Texture (MT standard), high gloss polishing |

Finish: | Mirror finish etc. |

Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Package: | Standard exported wooden box packed, fumigation process (upon required) |

Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

Annual production: | 250 sets of mold |

- Q: What is the mold for?

- Mould as a special kind of mechanical products, mould industry as a special kind of machinery industry, not like other mechanical industry & mechanical products, mechanical products made of research and development of the province produced parts or mechanical products design theory design alone would eventually basic guarantee to achieve the required by the function and use requirement, that is, for most of the other mechanical products, if can complete the whole processing or as far as possible to reach the design precision and requirement, the final product and original design purpose is to won't have too big deviation, the perfect design under the guarantee of processing conditions can produce perfect products, at the same time, this kind of product design theory basis after decades or even in some of the old capitalist countries hundreds of years of continuous research and actual production under the mutual development of has become very mature, very perfect, very practical, such as various kinds of machine tool equipment, power equipment, etc.

- Q: Can you tell me how the injection molding machine has a large closing line and the batch front?

- Like the first floor of the adjustable or no problem but you should pay attention to mold exhaust good with the bad, there are many reasons a inside,,, that is, experience, hope you more like the best I am a maintenance of injection molding machine, hydraulic or servo principle is the same

- Q: Is there a difference between die and CNC

- Need to master the tools design process of the tools and materials required for the performance of the design of CNC is mainly for nc machine tool operation, need a digital programming reference drawings

- Q: What is die parting face?

- A mold term. Mould is, generally speaking, there are two major components: dynamic model and fixed die (or male mold cavities and cores), parting surface is closed and state can contact between the two parts, is divided into the workpiece or mold parts mold parting plane of block size, has a broader significance. The design of fractal surface directly affects the quality of the product, the difficulty of mold structure and operation, and is one of the key factors in the success of die design. The following principles should be observed when determining the parting surface: (1) make the mold structure as simple as possible. If you avoid or reduce the side parting, you will reduce the movement of the type and the fixing of the mold to reduce the difficulty of processing. (2) it is helpful for the smooth removal of plastic parts. As long as the mold is left to be left on the edge of the moving die to make use of the top of the injection molding machine, avoid the long distance core to reduce the size of the die. Ensure the precision of the product. To minimize manufacturing and assembly errors, as far as possible, in the same module as possible. (4) not affecting the appearance of the product. The flying side inevitably occurs at the parting surface, so avoid the design of the parting surface on the smooth surface. (5) ensure smooth exhaust of the cavity. If the fractal surface is as close as possible to the final filling of the cavity wall, it can be used to exhaust the cavity.

- Q: What is a molds? What is the difference between die and die?

- Under external force, the material is made into a special shape and dimension. Widely used in cutting, forging, cold heading, extrusion, powder metallurgy parts suppression, pressure casting, as well as engineering plastics, rubber, ceramics and other products of the molding or injection forming. The mold has a certain contour or inner cavity shape, and the shape of the blade can be applied to the outline Separation of forms (blanking). The inner cavity shape can be used to obtain the corresponding solid shape. The mould usually includes two parts: the moving model and the mold (or the punch and the concave), which can be divided into two parts. When apart, take out the pieces and put them into the mold cavity forming. Mold is a precision tool, complex shape, bear the expansion force of billet, the structural strength, stiffness, surface hardness, surface roughness and machining accuracy have higher request, the development level of mold production is one of the important symbol of the levels of mechanical manufacturing.

- Q: What is a mold bite

- Is lousy skin grain, a lot of plastic parts surface is very thick leather grain, like a car instrument on the stage or storage battery mirrors, etc., fine grain with spark machine can play out, but do not to come out of coarse grain, you need to use chemical liquid will need mold cavity rotten into grain, also called texture

- Q: What is the difference between a mold and a handboard?

- Hand refers to do manual model, general use plastic stick on machine tools or machining centers or in the form of a similar casting, made by hand, not mass production. And open mode is to point to the processing mould first, then use mould injection molding or blow moulding moulding to produce the product. In general, it is used to confirm the shape of the customer by hand plate mould.

- Q: Make the mold with the dough

- Don't know what material are you going to make up, but the estimate is made of liquid class can be solidified material. So note that, if the material to be heated to a liquid to prevent the high temperature burn silly putty cavity (silly putty is usually made of flour and salt). In addition to prevent leakage of liquid. (recommended materials choose gesso)

- Q: What is the top and bottom die in the mould?

- Hello, before you answer your question, I want to tell you that you are just as misguided as any other student. Moulds itself no, under the touch, it's like: two tiles together, we can't say targeted on brick, brick, if there is a mould of lower die on concept, studied physics knows, it is need a reference or a reference point. Two cavity, the most common type of mold is the so-called two mould, is there are two main cavity, you can control open mould, also can open mould, therefore, only under the condition of upper and lower mould work, just have upper die, the meaning of the lower die.

- Q: The wall thickness of the die is affected by the plastic parts

- For thermoplastic materials, the cooling time is added For thermosetting materials, solidification is not complete.

Send your message to us

PET Preform Plastic Molds Injection PET Moulding Top Level

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords