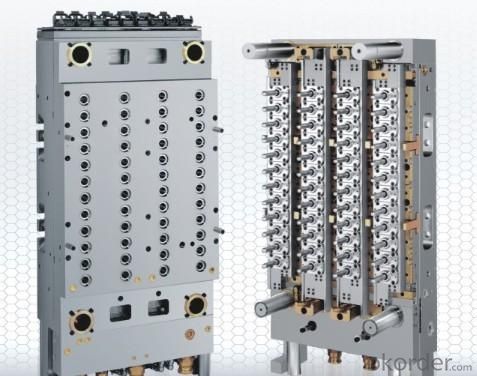

Pet Mould Making Plastic Injection Pet Preform Mould amd Pet Blow Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pet Mould Making Plastic Injection Pet Preform Mould amd Pet Blow Moulding

Plastic injection Mould standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM STANDARD | |

| 2 | Mould base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

| 3 | Material main core and cavity insert | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| 4 | Hardness of steel | 46~56HRC |

| 5 | Material for Slider ,Lifter and all sub insert use | 1.2767 HRC |

| 6 | Cavity | Single-cavity ,Multi-cavity |

| 7 | A surface request | EDM & High Polish |

| 8 | Gate | Cold runner,Yudo/DME/HASCO/Synventive Hot runner |

| 9 | Maximum mould size | 1500*1500 mm |

| 10 | Mould life time | 500000~+1,000,000 shots |

| 11 | Quality | ISO9001-2008 certification |

| 12 | Product material | PA,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE etc |

| 13 | Lead time | 4~6 Weeks |

| 14 | Package | Wooden/Plywood case for tool ,PE bags add export carton for parts |

| 15 | Payment terms | T/T |

| 16 | Trade terms | FOB XIAMEN |

| 17 | Export country | Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

| 18 | Value-added service | Polish,texture,painting,screen printing,turnkey project |

| 19 | As a professional Plastic Injection mould ,Die casting Mould & Moulding manufacturer, our range products are covered from Automobile,Electronic,Industrial,Household,Medical,Sport,Office etc | |

| 20 | Clients project's 3D drawings or samples are highly appreciated | |

Our Services

1. Can supply with both Mold & Molded parts

2. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

3. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

4. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

5. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

6. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

Product Description

Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

Quality: | ROSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

Surface Finish: | Texture (MT standard), high gloss polishing |

Finish: | Mirror finish etc. |

Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Package: | Standard exported wooden box packed, fumigation process (upon required) |

Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

Annual production: | 250 sets of mold |

- Q: How does the concave and convex mold in the mold differentiate

- The convex model and the concave model are distinguished by the shape, which is an image. It is the basic classification of cold die, but it is not absolute. In the composite mode, the convex mode can also be the concave mode, the convex cavity. There is a hole in its shape, it is a concave mode, but it is a convex mold, which is used for punching and falling. In the plastic mould, the common punch and the concave die are mounted on the mold, the moving mode or the moving die. However, it is not necessary that some of the molds and concave models are also on one side, fully loaded on the moving die, which is only a flat plate, with only a feed hole. - gallium xuan steel

- Q: What does a factory do?

- The mold factory is to make the mold, the stamping injection moulds what It also has milling and heat treatment

- Q: What is a compression mold?

- The main equipment used in compression moulds is press and mold. The most commonly used are self-contained hydraulic presses, which range from dozens of tons to several hundred tons. Have lower pressure press and upper pressure press. The molds used to compress moulds are called press moulds, which are divided into three categories. Overflow mold, semi-overflow mold and mould. The main advantage of the compression mould is that it can be moulded by larger planar products and mass production, and its disadvantages are long production cycle and low efficiency.

- Q: What is the role of the guide in the mould

- The most common guide is the guide. In addition, large molds may set up the guide, and the microdie may set up the catheter, which is the same as the guide.

- Q: What is the role of the grooves in the guide column

- Storage of lubricating oil and cutting groove action. Because of the relative motion of the guide when the guide is working, because the clearance is small, the oil can be scraped off for a long time. So the design of this groove allows the lubricant to stay on the length of the guide column, not all of it to the end. Because the processing accuracy is different on both sides of the guide. Level 2 orientation precision, for example, sliding guide part of guide pillar and guide bush of requirement is H7 / h6, guide pillar of the fixed part and the mold base with the mounting holes is H7 / s6, relief groove guide pin can be divided into two sections, one section for h6, another for s6, so relief groove is a must have!

- Q: The characteristics of cold making die steel

- It is widely available in cold steel: high hardness, high wear-resisting, high compressive strength and quenching performance Cold stamping die, stamping die, drawing die, extrusion die and so on

- Q: What is the purpose of the mould

- The mould is the most widely used in the industrial production, the die industry is the basic industry of the national economy. Widely used in modern industrial production, product parts forming, extrusion forming, stamping, die-casting, forging forming, plastic injection, or other forming method, and the forming mould, make the billet forming parts to meet the requirements of the product. The development of many industries, such as electromechanical, automobile, light industrial, electrical appliance, communication, weapons, etc., depends on the development of the technology of the mould industry.

- Q: What is the difference between a mold and a handboard?

- Although there are so many differences between planks and mould, but they still have contact, generally use hand-board model to the customer to confirm the shape first, confirmed to open mold production. The cost of many physical molds is generally high, with large molds valued at 100,000 or even millions, especially in the medical industry. If there is a structural unsound or other problem in the process of installing the die, it will be very large. The handboard model can solve the problem of this loss, reducing the risk of making physical models.

- Q: What is the discharge in the die

- If from microscopic description: discharge machining principle is by mechanical control makes the negative electrode, infinite close to, but it does not contact the positively charged artifacts, produce strong electric fields. , resulting in a very big impact on the periphery of the insulating liquid particles electrons, enable a large increase its electron number in the form of a pyramid, then bombarded with extremely high acceleration and speed atomic particles on the surface of the workpiece, make its produce high temperature after fall off under the action of explosive force. Of course, the atomic particles of the electrodes are also bombarded by positive ions, causing the heat to fall off as a result of the blasting force. At the same time, a certain number of positive and negative ions and a large number of neutral particles are produced in the process. Then, some of the positive ions move to the side of the electrode and attach to the surface of the electrode, causing it to compensate for the loss. Partial negative ions are moved to the side of the artifact and attached to the surface of the artifact. At the end of the day, when a wave of repulse is working, all the shedding will be washed away with the insulating fluid. In practice, when we use different conditions, we have different roughness, velocity, loss, spark bits. The reason for this is that in the process above, it is best to synchronize the various changes in time. Of course, there is also the thermal conductivity of the electrode and the material of the workpiece. The melting point. The physical properties and the media of the density are very important.

- Q: Would you please tell me what the difference in the mold Tooling and mold

- Please say on the injection molding product is marked: 5200 is the mold material is 5200 or what?

Send your message to us

Pet Mould Making Plastic Injection Pet Preform Mould amd Pet Blow Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords