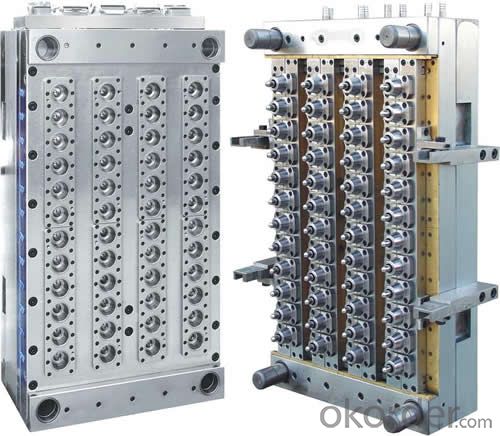

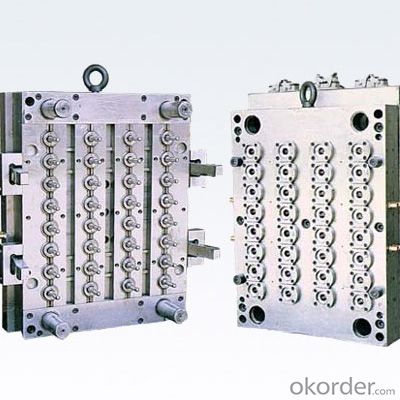

Plastic Injection Mould Multi-cavities Hot Runner Plastic PET Perform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

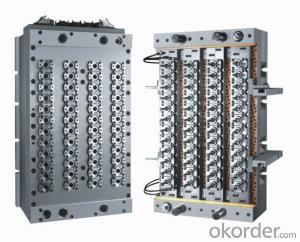

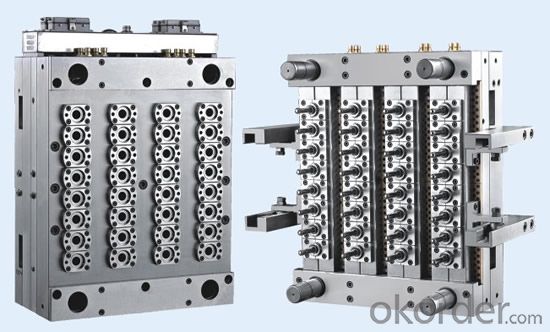

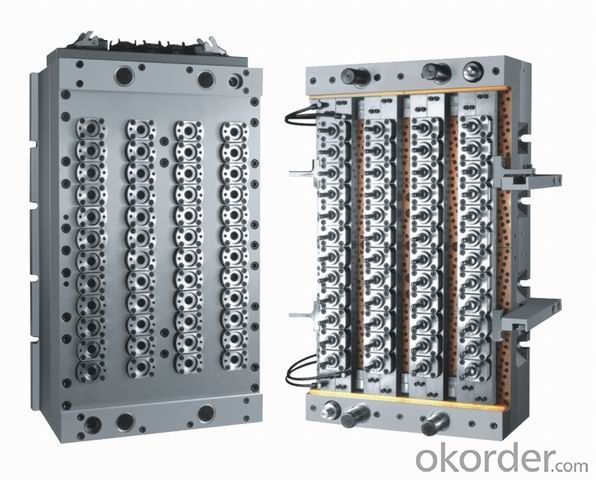

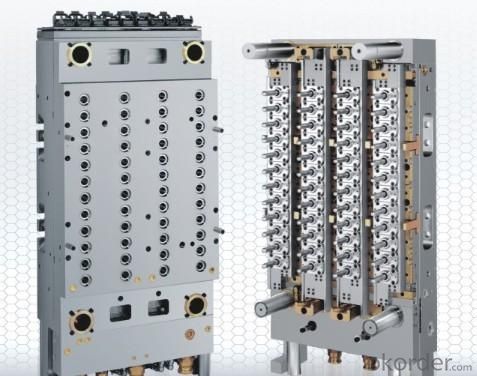

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

.Off-center Adjustment System

Off-center adjustment system can make the error of preform’s wall thickness less than 0.05mm. This system does not affect the lifetime of mold;

.Self-lock System

International advanced bi-awls fixed orientation self-locked structure has been adopted.

.Cooling System

All the water Channels in the mold’s each inner part, which make the cycle time short enough. And all the cooling channels have been specially treated to prevent them from jam;

.Heating System

Double Heating System can ensure that the impact of heating is good and quality control is credible. The Heating Band unit makes nozzles be with invariable temperature. The Heater Unit is used to heat the hot runner plate with long using life and powerful heating capacity.

.Hot Runner System

The perform mold adopt Pin-valve type Hot Runner System, such hot runner system can reduce mold’s each part’s wear & tear and maintenance cost, and also save 10%~15% electric energy;

.Hydraulic Ejecting System

The perform-doffing success ratio has achieved firm endurance and the whole perform ejecting process will become much quieter.

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

PET preform injection mould with normal long tail availabe.

short tail mould available.

valve gate without tail mould availabe.

4~48 cavity mould as customized.

23 years experience of preform mold specialized manufacture.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: The processing method of the mold cavity processing center

- Is the mould inside the groove, and the cavity. Now more than a touch cavity more and more, and most of the high precision, high mould has the characteristics of complexity. Higher up best precision machining center, if the volume is big, also have to gantry machining center, pentahedron gantry machining center, will not have what problem

- Q: How do H13 mould steel heat treatment

- 1. Preliminary heat treatment in the market supply of H13 steel and die steel billet, in the steel mills have prepared annealing heat treatment, ensure the good metallurgical structure, proper hardness, good processability, and no longer annealing. But factory to change after forging has destroyed the original organization and performance, stress, increased the forging must be annealed. Isothermal spheroidizing annealing process for: 860 ~ 890 ℃ heat insulating 2 h, cooling to 740 ~ 760 ℃ isothermal 4 h, furnace cooling to about 500 ℃.

- Q: How expensive are the molds, or how expensive are they? Which quality is better?

- How expensive is the quality and how do you use them.It is more expensive to choose which one depends on your batch size.

- Q: What does the mold and the flying model mean

- It's the match model. If you know what to do with the fitter, you will know that it is the place where the higher ground is polished and the uneven ground is polished. Fly mode to use to the red lead, similar to Indonesia, the two sides laminating will have red mark, where sealant plane if there is no stamp, just sign here has a problem, will need to be polished. And this process is called the flying model. You still need to see it on the ground.

- Q: What are the types of molds?

- Mold can be divided into metal mould and non-metal mould. The metal mould is divided into: casting mould (non-ferrous metal casting, steel casting) and forging die etc. Non-metallic mold is also divided into: plastic mould and inorganic non-metallic mould. And according to the material of the mould itself, the mold can be divided into: sand mold, metal mould, vacuum mold, paraffin mold and so on. With the rapid development of polymer plastics, plastic mould is closely related to people's life. Plastic mould can be divided into: injection molding mold, extrusion molding mold, gas auxiliary molding mould and so on. Large-scale production of non-sheet metal parts - cold heading, die forging, metal mould, etc. molds

- Q: How many types of molds? Please help me out!

- The classified method of plastic mold profile at 11:30 on Friday November 7, 2008 mold is one of the important technology and equipment, modern industry is an integral part of many industrial products production. After China's accession to the WTO, the ability to attract foreign investment increased year by year, the increasingly prominent position, to become the world manufacturing factory of all kinds of industrial products mold imports more and more. The type of mold is usually carried out in accordance with the process of processing object and different classification, from the industry point of view to see the distinction between the main plastic mold, rubber mold, metal cold punching mold, metal cold extrusion die and hot extrusion die, metal drawing dies, powder metallurgy mold, metal die-casting mold, metal precision casting die mold, glass, glass fiber reinforced plastic mould and so on. Although there are many kinds of molds, the main items in the tax classification are the items of the tax items 84.80 and 82.07. The following is a description of how different types of molds used in the most common plastic processing are described. Plastic forming method of the most common general divided into two categories: the melt molding and solid phase is melt molding plastic heat to above the melting point, make the molten forming way, belongs to the molding methods of molding process mainly include injection molding, molding (shrinkage) molding, extrusion molding, etc; Solid-phase molding refers to a type of forming method in which plastic is kept solid under molten temperature

- Q: How long is the life of die casting die?

- Aluminum: 120000 times Copper: 20000 times Magnesium: 200000 times Zinc: 500000 times Benchmark, the product structure added and reduced die life

- Q: What certificate does the mold major need to take an examination?

- (1) AutoCAD is a software that is easy to learn and can be used as a basis for CAD, which is software for almost everyone in the industry. This is a two-dimensional software that doesn't have to learn its so-called 3-dimensional function because it's basically not used for 3-d purposes. Once you've learned the software, you can stay at this stage and learn one of the two 3-dimensional software. (2) the Pro/E (weak) design function, programming (3) the UG (design aspects as Pro/E, but programming function is stronger) which of the two 3 d software to learn. If you want to improve your mold design ability, consider taking part in a training session. After training, you will be able to get a real job.

- Q: How do you handle the die holder

- Mold clamp mouth usually refers to the Parting surface, Parting line or the Parting line), including the slider, inserts, lifter and so on between the two in the products with line. Note: CNC processing aspect: parting surface machining with rubber products, at the same time to the mold clamp mouth do protection processing, die fillet directly in the machining process can be avoided; To remove the electrode: the separation of the Angle electrode and the electrode of the product is removed and the Angle of the die is avoided in the EDM process. Mold, industrial production to be used for injection molding, blow molding, extrusion, die-casting or forging, metallurgy, stamping, etc., to get the various mold and tools of the desired product. In short, the mold is a tool for molding objects, which are made up of various parts, and different parts are made of different parts. It mainly USES the physical state of the forming material to realize the processing of the physical appearance. There is the title of "mother of industry"

- Q: What is the pull mold

- Used to pull metal plates deep into cups or curved parts.I hope my answer will help you.

Send your message to us

Plastic Injection Mould Multi-cavities Hot Runner Plastic PET Perform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords