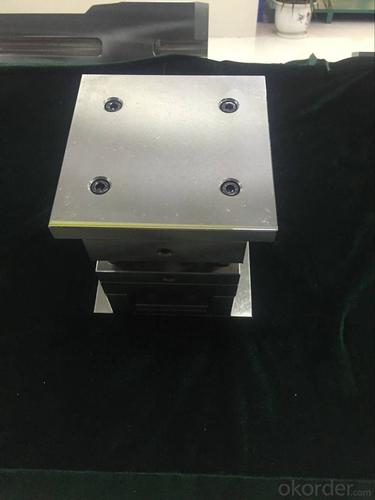

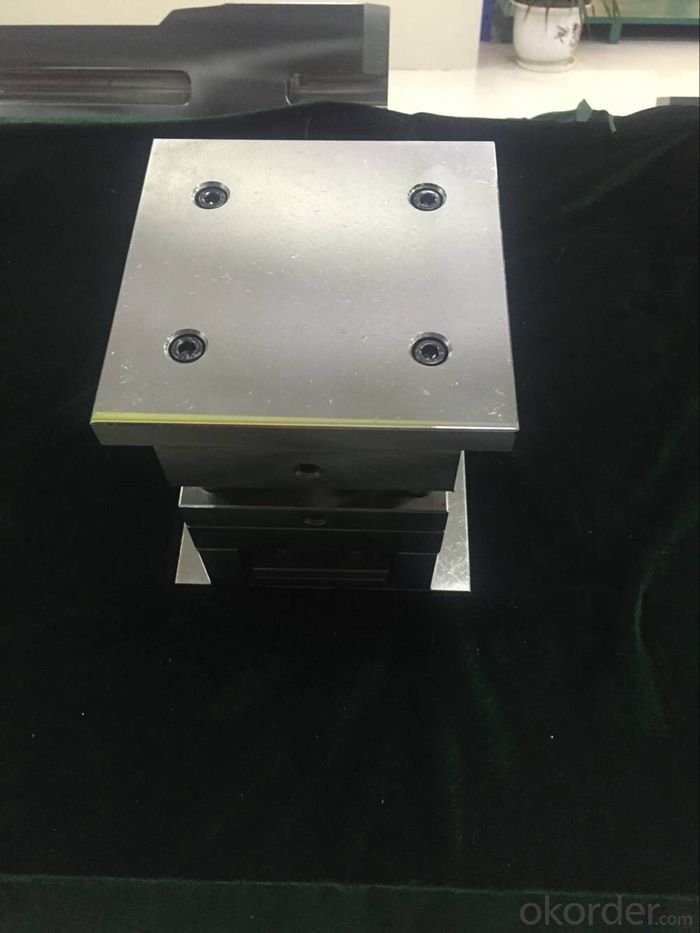

Stamping Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

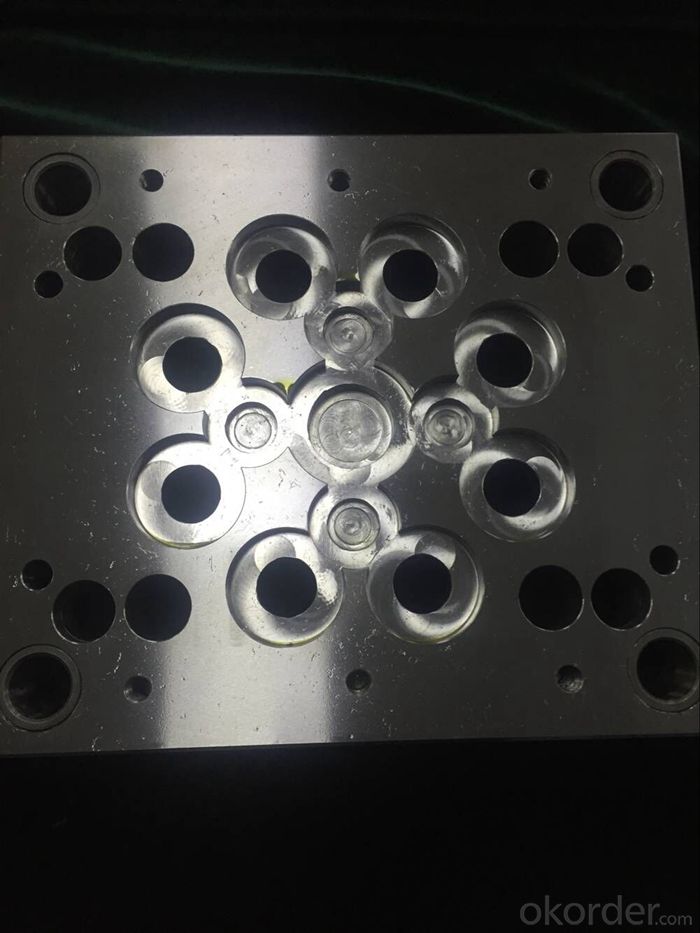

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q: What is the material of hot pressing die?

- 5Cr4W5Mo2V (RM - 2) steel, more than 3Cr2W8V steel, has higher heat intensity, abrasion resistance and thermal stability. When the hardness of 40 HRC thermal stability of up to 700 ℃, suitable for the production of hot extrusion mould.

- Q: Is the slanting and shoveling chicken in the mold the same thing, shoveling the chicken? Where is it used?

- I have never heard of what it is called The main function of shoveling a chicken, which is also called a slider lock block, is to compress the slider There is another type of spatula in front of the former mold which is the top of the chicken It's double insurance on the back

- Q: What does it mean to have a rough die

- The tool is used to process the rough shape of the mould. And the machine tool and cutter that open coarse use is less accurate, such processing speed is relatively quick. It needs to be left with a residual amount, and then replaced with a processed machine tool and tool. Die strategy: Follow the perimeter: less knife, more clean blade, more empty blade, suitable for electrode processing, avoiding the phenomenon of the cutting of the knife in electrode processing. Follow the workpiece: it is not easy to cut, the way is safe, it is suitable for steel material processing, lifting the knife.

- Q: Is there a difference between die and CNC

- In this industry for a long time, such as the above mentioned anything very tired what some content (which is fitter), such as after contact with these can promote the theory knowledge, can such as the door. Has a common characteristic is one of the two mold design knowledge, the knowledge of the actual mold edge or the manufacture of understand relevant knowledge, above all, the mould design of the road is long, don't be afraid of bitter, in front of the stick behind natural results. The numerical control is relatively less long-term, learn to do, the big deal starts from the foundation. Relatively simple. If you haven't learned it, you can do it, you can do the operator, it's the machine, you move the parts. The treatment is basically between 1,500 and 3,500, and of course there are over 4,000, very few, after all, it's manual labor, it's a piece of work, it shouldn't be done in a few months. The real technology is to learn. The first is programming.

- Q: How to calculate the cost of plastic mould?

- Mold calculation cost is actually very simple, mold steel and toll fee counting and personnel salary, these are the main three cost, mould quotation I do work more than ten years, the products are numerous, I have a look at any plastic products will be able to know the price, if I can help you have drawings or samples

- Q: What are the main problems of the mold?

- You're talking about a broad mold. Most molds now refer to steel moulds (ordinary die casting molds, plastic moulds, stamping molds) Of course plastic wood sand can be used in a broad sense The molds (moon cakes and pastries) made of food are made of wood Cast iron is a lot of sand

- Q: What is the manufacturing of mould materials

- You're talking about the industry that makes moulds. It is the metallurgical industry that makes mould material. From steelmaking to forging and rolling, it also belongs to heavy industry.Belong to die design, consider the choice of suitable material.

- Q: What does the mold slow wire do

- Walking wire electrode is used copper wire, fast wire with molybdenum wire, and fast wire is used in reciprocating, slow wire can only be a one-off, slow silk machine, of course, price is high, the processing fee is high also, processing product quality is high

- Q: What is the top and bottom die in the mould?

- Hello, before you answer your question, I want to tell you that you are just as misguided as any other student. Moulds itself no, under the touch, it's like: two tiles together, we can't say targeted on brick, brick, if there is a mould of lower die on concept, studied physics knows, it is need a reference or a reference point. Two cavity, the most common type of mold is the so-called two mould, is there are two main cavity, you can control open mould, also can open mould, therefore, only under the condition of upper and lower mould work, just have upper die, the meaning of the lower die.

- Q: The core is the moving or the model, male or female?

- The moving mode is the common mode. In the case of the core, the frame of the frame is called the core, which is the core of the moving model and the core of the static model

Send your message to us

Stamping Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords