Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

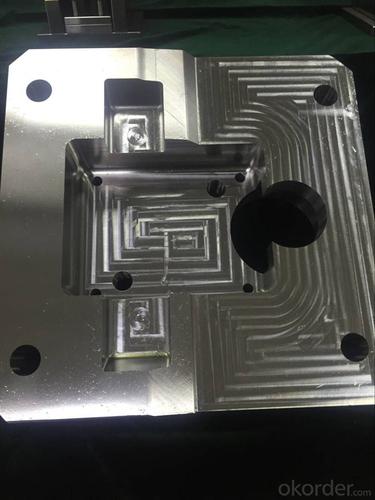

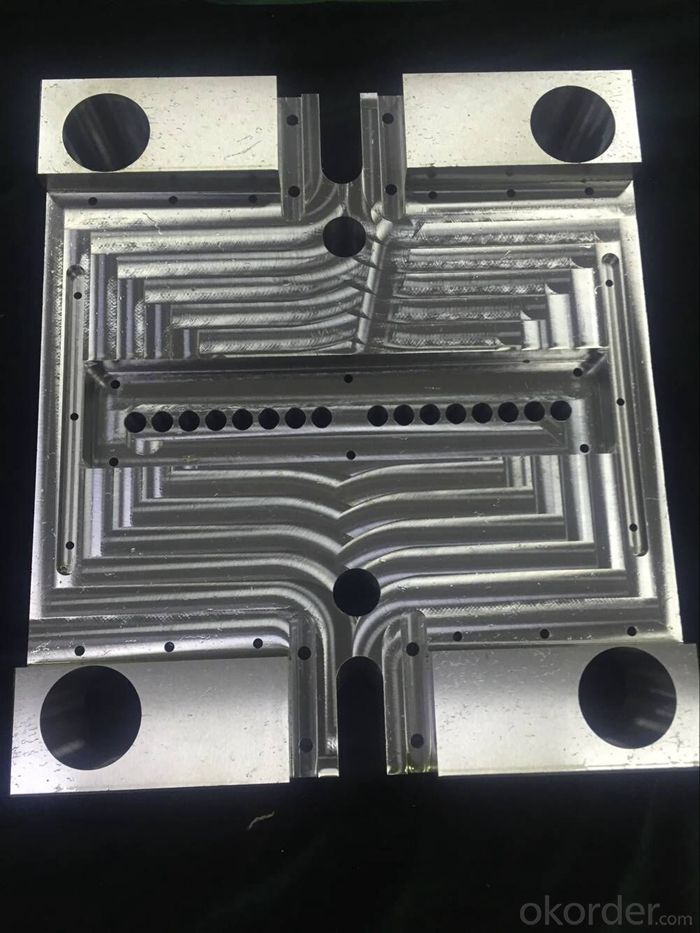

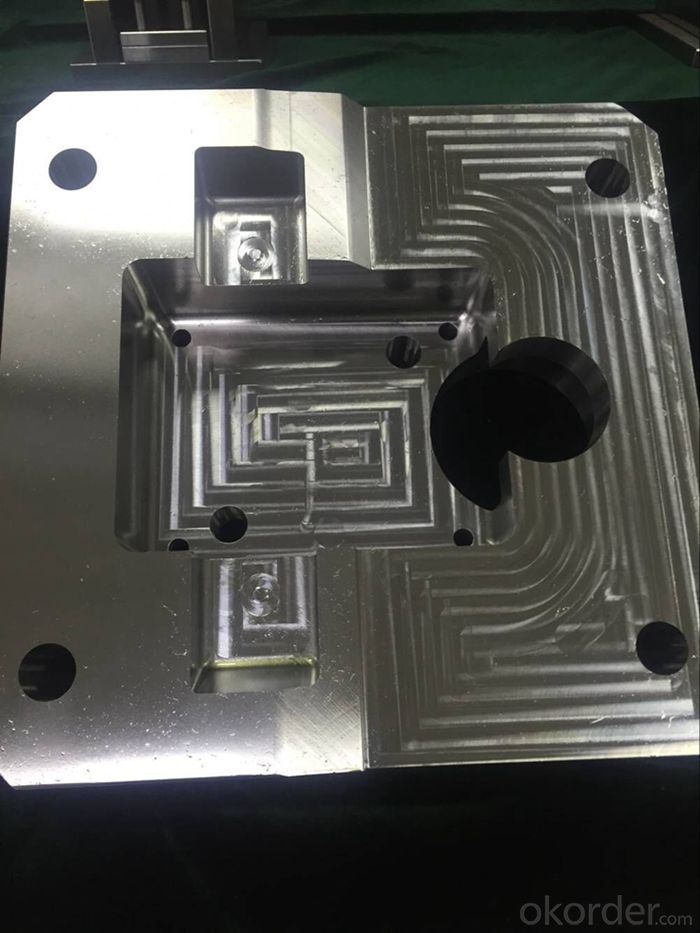

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q: Is the slanting and shoveling chicken in the mold the same thing, shoveling the chicken? Where is it used?

- Oblique woven so rarely General said shovel chicken (tackle) you know oblique woven should know shovel base, its function is used to compress the slider, prevent when glue by shoot rubber pressure make the influence of the slider in the back.

- Q: The characteristics of cold making die steel

- It is widely available in cold steel: high hardness, high wear-resisting, high compressive strength and quenching performance Cold stamping die, stamping die, drawing die, extrusion die and so on

- Q: What is the number of holes in the mold?

- That's the number of modules It's usually professional to say that the mold is a few lumens An eight cavity means that the mold has eight holes that are capable of eight products

- Q: What does the mold and the flying model mean

- It's the match model. If you know what to do with the fitter, you will know that it is the place where the higher ground is polished and the uneven ground is polished. Fly mode to use to the red lead, similar to Indonesia, the two sides laminating will have red mark, where sealant plane if there is no stamp, just sign here has a problem, will need to be polished. And this process is called the flying model. You still need to see it on the ground.

- Q: What is a mold?What is it mainly used for

- Molds are a kind of tool that can be made in batches. It has a lot of types, hardware, plastic, and so on, and as the industry develops, its use is getting bigger and bigger and better. Through the mold can do a lot of things, daily use articles for daily use, basin. The POTS, pot, etc., there are many high-tech products are made with mold to form the batch. It is also very useful in the automobile industry, so it will be more and more effective in almost all of life. It's also easy to learn, as long as you're careful.

- Q: Mold design and manufacturing to learn which courses

- This major is mainly aimed at machinery manufacturing, and develops the design and manufacture of cold stamping die, type cavity mold and its design and manufacturing. Main courses: mechanical drawing, mechanical design basis, electrician and electronic technology, engineering materials and heat treatment, mould manufacturing technology, mould CAD/CAM. Jobs: workers, molds manufacturing personnel, mechanical maintenance personnel, production management personnel. Tuition is too expensive This is a professional professional, and it's easy to find a job. The school that runs this major is very few in the vocational technical college Jobs: workers, molds manufacturing personnel, mechanical maintenance personnel, production management personnel.

- Q: How does the die rod work? Is it through the press?

- The rigid push device usually consists of a rod, push plate, connecting rod and push piece.

- Q: What is suitable for moulding steel

- Cold rolled molds include cold die, wire drawing die, drawing die, press die, thread rolling die, roller plate, cold press and cold extrusion die. Cold work die steel, according to the working conditions, and should have high hardness, strength, abrasion resistance and sufficient toughness, and high hardenability, hardenability and other process performance. Used for such purposes of alloy tool steel is generally belongs to the high carbon alloy steel, carbon mass fraction 0.80%, chromium is one of the important alloy elements such as steel, its mass fraction is usually not more than 5%. But for some high requirement of abrasion resistance, small deformation of mould steel after quenching, high chromium mass fraction is 13%, and in order to form a large number of carbide, carbon in steel quality score is high, up to 2.0% ~ 2.3%. The carbon content of the cold steel mold is high, and its organization is mostly in the form of a di-di-steel or lystenoid steel. Commonly used steel types have high carbon low alloy steel, high carbon high chromium steel, chrome molybdenum steel, medium carbon chromium tungsten steel, etc.

- Q: What do you do with the exhaust? How are we going to

- The exhaust tank has two main functions: One is to exclude the air in the cavity when the fuse is fused. The second is to eliminate all kinds of gases produced during heating. The more thin wall products, the more distant the part of the gate, the opening of the exhaust slot is especially important. For small pieces or precision parts also should attach great importance to the opening of the exhaust slot, because in addition to it can avoid products surface burns and injection quantity is insufficient, also can eliminate the various defects of the products, reduce the pollution of the mould and so on. So how does the exhaust of the cavity be sufficient? In general, if the injection rate is injected at the highest injection rate, it is not left in the product, and it is considered sufficient to exhaust the cavity in the cavity.

- Q: The core is the moving or the model, male or female?

- In general, most of the mold core is dynamic model (male), cavity is fixed mold cavities (), but a small part of the mould, called inversion model, the product is no nozzle design, mold core is fixed mold (die), cavity is dynamic model (button).

Send your message to us

Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords