Preform Injection Molding PET Preform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

PET Preform Injection Molding from 1-cavity for wide mouth jar and gallon bottle perform up to 72-carrow neck perform mold; Tube blank is designed with the help of computer, which surely contributes to the increasing of yield of bottle;

Employed internationally advanced two-step dual taper locating technology. Each cavity self-locks independently to ensure low decentration of product;

Core and cavity are made of special mold steel after preheating treatment in the original factory in Sweden. Individual tempera-ture control of each cavity;

Lip cavity is made of imported nitrated steel, which is of high hardness and long service life, in accordance with international standard;

The cavity is made of imported nitrated steel, which is of high hardness and long service life, in accordance with international standard;

The excellent hot runner design assures uniform heating and improves greatly of the plastic product quality;

No cutting of gate is employed to reduce the labor intensity;

Standard inter-changeable mold components;

The life of mold is more than 3 million times.

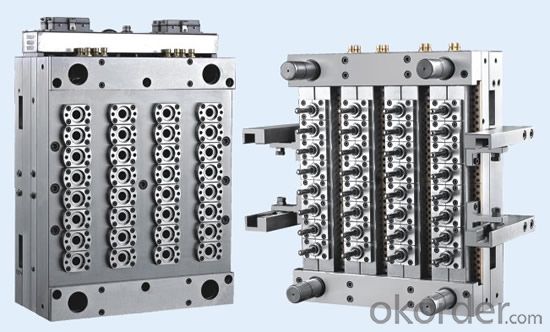

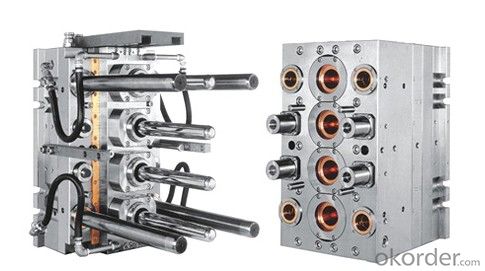

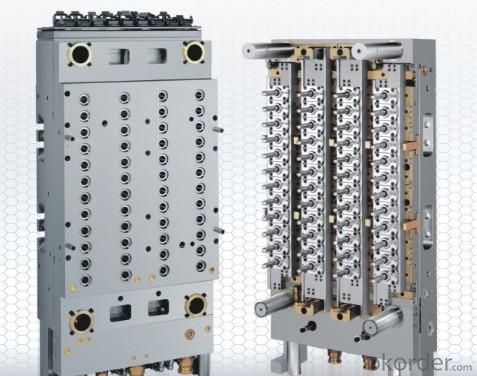

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

PET preform injection mould with normal long tail availabe.

short tail mould available.

valve gate without tail mould availabe.

4~48 cavity mould as customized.

23 years experience of preform mold specialized manufacture.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: The characteristics of cold making die steel

- It is widely available in cold steel: high hardness, high wear-resisting, high compressive strength and quenching performance Cold stamping die, stamping die, drawing die, extrusion die and so on

- Q: What is the difference between the p20 mould steel and the nak80-b mould steel

- It's completely different, the composition is different, P20 is 3Cr2Mo, and NAK80 is 10Ni3MnCuAl

- Q: Is the digital control the same as the mold? If not, what's the difference?

- CNC is short for computer numerical control can also be called CNC is the operator input according to drawing processing program through computer processing, to send signals to the controller, the controller issued a directive driven motor motion of a device, it is widely used in modern machine tools, Mold, could be called the "father" of the product, because most of the industry, including daily life things are completed by mold, such as we drink bottles, glass He is prior to the shape of the product on the nc machine tool processing good, then through injection molding machine casting, The two are related but not the same thing

- Q: What is the number of holes in the mold?

- That's the number of modules It's usually professional to say that the mold is a few lumens An eight cavity means that the mold has eight holes that are capable of eight products

- Q: How many products can a mold make?

- Simple molds are less, a good order of hundreds of millions of molds can be done, but some parts need to be fixed regularly

- Q: What is the difference between mould injection and blow molding?

- Blow molding: also call hollow blow molding, a kind of development rapid plastic processing method. Thermoplastic resin by extrusion or injection molding of plastic parison tube, hot (or heated to softening state), put in split cavity, mold closing immediately after ventilation with compressed air within the parison, make plastic parison swell and clingy wall in the mold, the cooling mold release, the products have all kinds of hollow. Blown film manufacturing technology on the principle and hollow blow molding is very similar, but it does not use the mould, from the perspective of classification of plastics processing technology, molding process is usually included in the extrusion of blown film. The blow molding process was used in the production of low-density polyethylene small bottles during world war ii. In the late 1950s, with the development of high density polyethylene and the development of blowing and molding machine, blow molding technology was widely used. Hollow containers can be up to thousands of litres, some of which are computerized. It is suitable for the plastic polyethylene, polyvinyl chloride, polypropylene, polyester, etc., and the empty container is widely used as an industrial packaging container.

- Q: The injection molding round box is not satisfied with the molds.

- Heat the mold with the temperature of the mould, then speed the injection a little faster, and then cool it when it is full.

- Q: Because many of the molds in our factory have batch sewing, who can tell me how to fix the batch seam. Because I don't understand, but I'm going to learn, so I want to know in advance, thank you very much!

- In the case of the building Lord, all the moulds have a lot of wind, which is that the injection molding machine is not enough

- Q: What are the five systems of plastic mould?

- Top out system, cooling system, exhaust system, casting system, molding system.Top out system, cool but system, molding system, casting system. All I know is that the four systems have not heard of five in the department.

- Q: The wall thickness of the die is affected by the plastic parts

- Wall thickness is high, thin wall is not enough, The wall is not uniform, and the stress concentration is deformed The thin wall is easy to hold, fill insufficient, the process is difficult to adjust, poor high

Send your message to us

Preform Injection Molding PET Preform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches