Motorcycle Disc

Motorcycle Disc Related Searches

15 Motorcycle Tire Metal Corner Tape Radial Tyre Bleeding Motorcycle Rear Brakes Motorized Drapery Mitsubishi Mccb Intel Pc Stick Vinyl Trim Nozzle Ring Car Wheel Rim Moving Tape Car Dent Repair Tool Sliding Gate Track Classic Car Weatherstripping Little Injection Machine Marine Engine Control Cables Electronic Tracking Device Vinyl Tex Tyre Contact Area Car Rims And Tyres Black Rims And Tires Pine Faced Mdf Clear Tape Dispenser 28 Inch Rims Cinder Block Machine Electric Shock Security Device Vintage Sink Taps Automatic Brick Machine Vinyl Ester Pink Hockey TapeMotorcycle Disc Supplier & Manufacturer from China

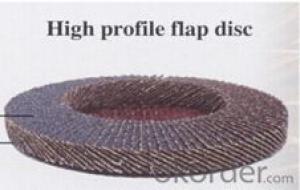

Motorcycle Disc, a crucial component for the braking system of motorcycles, is designed to provide efficient and reliable stopping power. These discs are engineered to withstand the demands of high-speed riding and harsh conditions, ensuring rider safety and control. The Motorcycle Disc is widely used in various types of motorcycles, from sports bikes to cruisers, and is essential for maintaining optimal braking performance. It plays a vital role in the overall functionality of the motorcycle's braking system, as it works in conjunction with the brake pads to create friction and slow down or stop the bike.In various riding scenarios, such as city commuting or off-road adventures, the Motorcycle Disc is indispensable for ensuring a safe and controlled riding experience. It is designed to handle the stress of frequent braking, providing consistent performance even under extreme conditions. The Motorcycle Disc's durability and reliability make it a preferred choice among motorcycle enthusiasts and professionals alike.

Okorder.com stands as a prominent wholesale supplier of Motorcycle Discs, boasting a vast inventory that caters to the needs of various motorcycle makes and models. With a commitment to quality and customer satisfaction, Okorder.com offers a comprehensive range of Motorcycle Discs at competitive prices, making it a go-to destination for both individual riders and businesses seeking to stock up on this essential component.

Hot Products