Abrasive Flap Disc for Rotary Polishing Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Abrasive Flap Disc for Rotary Polishing Use

Quick Details

| Place of Origin: | Zhejiang China (Mainland) | Brand Name: | Hotshine | Model Number: | AFD |

| Type: | Abrasive Disc | Size: | 4"~7" | Grit: | 40#~400# |

| Backing: | Fiber glass & Plastic | Adhesive: | Import glue | Abrasive cloth: | AO, XA, ZA, |

| Max speed: | 80M/S |

Packaging & Delivery

| Packaging Detail: | 10Pcs/Shrink, Export Carton |

| Delivery Detail: | 20Days |

Specifications

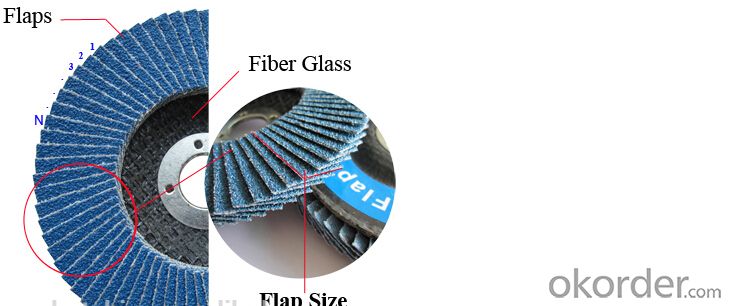

Abrasive Flap Disc:

Fiber glass backing;

High quality sand cloth;

High quality adhesive;

Very safty for using.

Flap discs are designed with abrasive cloth strips glued on to a rigid backing in a fan arrangement. Flap discs can replace in many operations, both grinding wheels and fibre discs. It is possible by using flap discs to cut and finish in one operation. The unique construction allows for new grain to be constantly in contact with the surface, as the flaps continually wear out. The life of a flap disc can be 20 times that of a fibre disc, resulting in a major cost reduction in both labor and material costs. A new heavy-duty product is available which gives high performance for weld removal on corners, flame cut edges, heavy deburring and cleaning of spot welds.

When removing the left over metal from the joint area, the motion of the grinder is the same as when using the rough grinding disc. Press the face of the disc into the work and work evenly around the tubing until it appears flush with the head tube shell.

Backing Plate:

Flap discs come with aluminum, fiberglass or plastic backing plates. Fiberglass is the most common. Aluminum is sometimes chosen due to no potential fiberglass dust hazards. Plastic backing is becoming more popular with some manufacturers suggesting that the plastic backing can be trimmed to increase working life.

Shape:

Flap discs are broken down into flat and angle face. Following grinding wheel terminology flat discs are type 27 while angle discs are type 29. Typical angle faced flap wheels are about 10°. Angle faced discs are more aggressive and are more suited to stock removal while flat faced discs are better on flat surfaces and will produce a more consistent finish.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Abrasive Flap Disc for Rotary Polishing Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords