Electrical Safety Inspection

Electrical Safety Inspection Related Searches

Electrical Distribution Block Electric Shock Security Device Electronic Bench Test Equipment Environmental Maintenance Electrical Connection Block Excess Electronic Components Electronic Tracking Device Electronic Assembly Equipment Recessed Emergency Light Emergency Rechargeable Light Environmental Standards Overhead Crane Inspection Environmentally Controlled Room Environmental Control Technician Emergency Rechargeable Lights Electronic Ordering Equipment Electrical And Equipment Sales Co Inc Environmental Control System Electric Chain Block Environmental Controller Electronic Encapsulation Electronic Equipment Recycling England Electrical Outlet Lift Electrical Electric Insecticide Sprayer Environmental Controllers Maintenance Of Environment Environmental Control Electrical Wholesalers Electricity Generation SystemElectrical Safety Inspection Supplier & Manufacturer from China

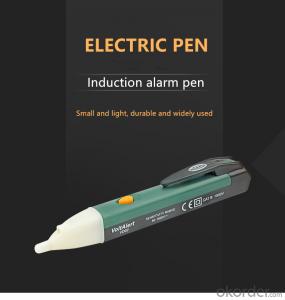

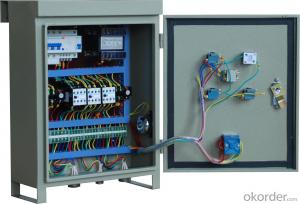

Electrical Safety Inspection encompasses a range of products designed to ensure the safety and proper functioning of electrical systems. These products include circuit breakers, GFCI outlets, and various types of electrical testing equipment. They are essential for maintaining the integrity of electrical installations in residential, commercial, and industrial settings.Electrical Safety Inspection products are widely used in various scenarios, such as routine maintenance checks, after electrical storms, or following any potential damage to the electrical system. Professionals in the field of electrical engineering and maintenance technicians rely on these products to identify potential hazards and ensure that electrical systems are operating safely and efficiently. By using these products, they can prevent electrical fires, protect individuals from electrical shocks, and maintain the overall reliability of the electrical infrastructure.

Okorder.com is a leading wholesale supplier of Electrical Safety Inspection products, offering a vast inventory of high-quality items. With a commitment to providing reliable and efficient solutions, Okorder.com ensures that customers have access to the necessary tools and equipment for conducting thorough electrical safety inspections. By partnering with Okorder.com, customers can benefit from competitive prices, fast shipping, and excellent customer service, making it a trusted source for all their Electrical Safety Inspection needs.

Hot Products