Environmental Control

Environmental Control Related Searches

Environmental Control System Environmental Control Systems Environmental Health Environmental Controllers Environmental Controller Environmental Administration Environmental Pollution Environmental Standards Control Environment Natural Environment Environmental Maintenance Clean Environment Environmental Control Systems In Buildings Environmental Control Technician Environmental Cleaning Maintenance Of Environment Environmentally Controlled Room Elements Of Control Environment Environmental Control Officer Regulations Control Environment Questionnaire Environmental Director Control Environment Components Environmental Cleaning Company Cleaning Of Environment Business Environment Cleaning Substances Maintenance Environment Surveillance Equipment Department Of Health And Environment Cleaning The EnvironmentEnvironmental Control Supplier & Manufacturer from China

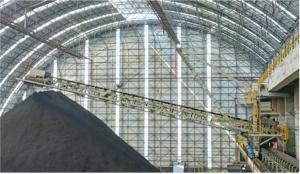

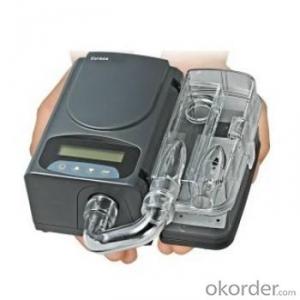

Environmental Control encompasses a range of products designed to regulate and maintain the conditions within a specific environment. These products are essential in various industries, such as agriculture, manufacturing, and residential settings, where maintaining optimal conditions is crucial for productivity and comfort. The products within this category include temperature and humidity control systems, air filtration units, and energy management systems, all of which contribute to creating a sustainable and controlled environment.The application and usage scenarios for Environmental Control products are vast, as they cater to the diverse needs of different sectors. In agriculture, these products help maintain ideal growing conditions for crops, while in manufacturing, they ensure that production processes are not disrupted by fluctuations in temperature or humidity. In residential settings, Environmental Control products contribute to energy efficiency and occupant comfort by regulating indoor air quality and temperature. This makes them an indispensable part of modern living and industry.

Okorder.com is a leading wholesale supplier of Environmental Control products, boasting a large inventory that caters to the needs of various customers. With a commitment to quality and customer satisfaction, Okorder.com offers a comprehensive selection of products that are designed to meet the specific requirements of different environments. By partnering with Okorder.com, customers can access a wide range of Environmental Control products, ensuring that they have the right tools to maintain optimal conditions in their respective settings.

Hot Products