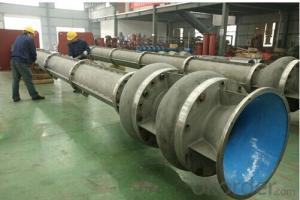

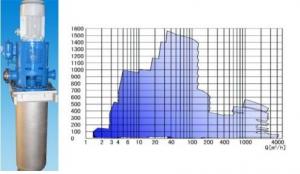

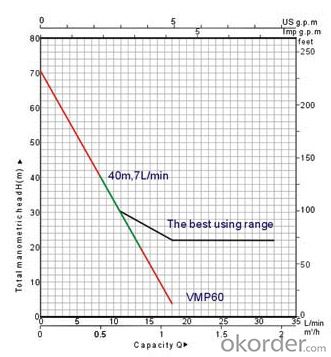

Vibration Pump VMP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| |||||||||||||||||||

VPM SERIES |  | ||||||||||||||||||

| |||||||||||||||||||

- Q: removed my water pump to replace it. i have the fan and clutch assembly still attached...i have no idea how to remove these...the fan clutch has bolts that hold the fan to it...and i did remove those but im just not sure how to separate this assembly...my water pump pulley has 4 holes...and no bolts so i presume it's pressed on...and there looks to be a very large nut between the pulley and the fan/clutch assembly...any help would be appreciated on this...i'd much rather go to the parts store w/ the old pump instead of guessing.....thnx in advance...

- Corrosion is now holding everything to the pump. Use a screwdriver to help separate them. Here is a link compliments of Auto Zone showing how to remove the water pump. You will note in the picture that the pump has a shaft sticking out of the front. That is holding the clutch and fan on. Earlier I gave you the wrong link. This is the correct one for the V6. The others were for the V8s They mention to remove the fan before removing the water pump. The fan should be bolted to the clutch in the manner you say. If you grasp the shaft on the pump, the fan and clutch should rotate freely. If you pulled the 4 bolts off the pulley, the fan and clutch assembly should come off. The pulley should then fall free. Is anyone else helping you with this and they already took the bolts out? If not you must have some alternate water pump that Chrysler failed to tell everyone about. Is the large nut against the pulley or the fan clutch? I wish we could talk on the phone. Get a mallet. Put the pump on a clean surface and use the mallet to tap the pulley on one side then the other. Hopefully this will help work this off. Once you get this off, you will see it should look like the pictures I sent to you. I just sent you another link that has 3 different ways they have the fan mounted to the water pump. Yes, there is a large nut holding the clutch on. It says it is a right handed nut so be careful taking it off.

- Q: What's the difference between a cold water pump and a hot water pump?

- Cold water pump refers to the pump can be transported below 80 degrees C temperature liquid, known as cold water pump, between 80 degrees C to 120 degrees C, the temperature of the pump is called hot water pump.1, the characteristics of hot water pumpHot water pumps IRG hot water pump which is based on ISG and ISW centrifugal pump series on optimization designed, especially IRG type hot water circulating pump consumption, because the pump adopts a vertical motor is installed in the upper part, and a short frame between the pump and motor, not because of a mechanical seal Water Leakage phenomenon the motor inside the water inlet of the motor burn, but also in the IRG based on the design of the hot water pump mechanical seal in high temperature hot water pump maximum temperature by external tap water cooling device can reach 240 DEG C.2, the characteristics of cold water pumpSeal packing seal or mechanical seal rubber material Ding Qing cold water pump commonly used, the most common packing pump is IS single stage single suction centrifugal pump of the pump is also one of the earliest water pump products, because the filler itself requires liquid cooling and lubricating the pump temperature as the only 80 degrees, and packing seal cold water pump and dripping phenomenon has pollution to the pump body pump base and the surrounding environment, this kind of product has been ISG and ISW centrifugal pump series products replaced, ISG and ISW series of cold water with mechanical seal it has no water leakage phenomenon, and is directly connected with the impeller structure used in the the shaft of the motor, the noise and vibration above is obviously better than that of the old type of IS series cold water pump this kind of pump products commonly used in air conditioning water cycle with so called air conditioning chilled water circulating pump.

- Q: I was driving when my temp gauge shot up all the way so i pulled off the next exit and my car shut off and started smoking i noticed the water pump belt was in shreds and what seemed to be anti freeze fluid and water was everywhere. I'm curious what could have broke maybe a gasket or the waterpump it's self besides just the belt?

- The bearings within the pump, or the belt tensioner pulley bearings, or even the alternator could have gone bad. Any one of the components that draw from the serpentine belt may be the origin.Once the engine cools it may be determined which component caused the failure. If the water pump turns freely then it's not the source and can be ruled out. Same with the tensioner pulley.

- Q: Fire pump room is required to set up water pump control room?

- What is the concept of fire pump control room? If there is a control room host automatic alarm automatic fire alarm system of words (through the pump distribution box can also control) can control the fire pump, if there is no distribution box automatic alarm system you can through the pump room control

- Q: 95 mustang leaking water pump changed the pump and its running backward now

- you have your belt on the opposite side of the water pump pully just gotta switch it around

- Q: I have a new water pump with its new gasket to be installed tomorrow. Do I still need to apply a gasket sealer (blue RTV silicone) on the gasket itself? If I do, do I need to apply it on both sides of the gasket? Thank you.

- that completely depends on the year/make and model, and type of gasket that it uses.

- Q: Question for you. I'm looking for a 12v (no AC converter, please) water pump to drive up to 4 water misters. Needs to run off the battery, without an AC converter (already found those). The pump will pull from a water reservoir and provide cooling relief on hot days through the misters. BTW... the pump should be reasonably small, limited to a few pounds...If you have any ideas, please advise.Thanks again,Robert

- Again, I'm going to make you work for this one. Call around to junk yards. See if they have any parts you can use. There's a bunch of Pull Apart places where you can look up online to see if they have any particular part you're looking for. I don't know how much a typical automobile water pump weighs, but I don't imagine it would be too big. Ask around. If you know any mechanics, or just people who work on cars as a hobby, they may know. Sorry I'm not much help in the automotive department. I can put gas in it, start it, change my oil, and change a tire. But as far as the rest goes, I don't know too much.

- Q: quot;A tank has the shape of an inverted circular cone (point at the bottom) with height 10 feet and radius 4 feet. The tank is full of water. We pump out water (to a pipe at the top of the tank) until the water level is 5 feet from the bottom. The work W required to do this is given byquot;I know how to find it if it's a right circular cylinder, but how do I adjust for the changing area? Also would a and b = 0 and 5? Thanks ahead of time!

- calculate the amount of water U start with by computing volume of cone: V = 1/3πr?h {r = 4', h = 10'} V = 0.333π(4)?(10) = 167.55 ft? calculate the amount of water remaining in cone after pumping is done: V = 0.333π(2)?(5) = 20.944 ft? calculate the volume of water pumped: 167.55 - 20.944 = 146.6 ft? 1 ft? of water weighs 62.4 lb, calculate weight of water removed: 146.6(62.4) = 9148 lbs The Center of Mass of the water in the cone (when h = 10') is at 1/4 of 10 ft = 2.5 ft high The Center of Mass of the water in the cone (when h = 5') is at 1/4 of 5 ft = 1.25 ft height The Center of C.of M. change = 1.25 + (2.5 - 1.25)/2 = 1.25+0.625 = 1.875 ft If we consider that the Center of Mass of the water removed was at 1.875 ft, All the water removed was then lifted an average of 10 - 1.875 = 8.125 ft Work done = W = (9148)(8.125) = 74,300 ft-lbs ANS

- Q: I will be replacing my timing belt soon. The dealer is suggesting that I also replace the water pump. Is that really necessary? When do water pumps normally go out?

- The only reason they say that is because 90% of the labor to replace a water pump is already done by removing the timing belt. So if you decline and the pump goes out, you'll pay all that labor all over again. If you change your coolant when due and use the right coolant (not some universal coolant), then no, pumps don't usually go bad. But it's all up to you and your level of risk taking. Most people get talking into it because the dollar risk is so high compared to the cost of a pump.

- Q: I have a quot;Rainbow Lifeguard Quiet One 6000external pump that I would like to use on a new chiller for my tank. The pump is rated at a little over 1500 gallons per hour. I'm debating between a couple of chillers, one that has a max flow rate of 1300 gph and another that has a max of 960.I know that you are only supposed to put any valves on the outflow side of the pump and lessening the flow to 1300 from 1500 doesn't seem like it would be that big of a problem, but I was curious it cutting it back to 960 would be hard on the pump in the long run. (I'm leaning towards the bigger chiller as although it may be overkill for my tank, it would let me have a little more water circulation.)

- I wouldn't restrict it more than about 10% or so personally. I would ask you to think about this: The rated flow rate on a pump is under perfect operating conditions and is usually a mathmatical model that cannot really be acheived in the real world. Your pump probbaly is several gallons per hours behind that. If the tank is on a stand and the pump on the floor, the head pressure alone may slow it to 1300 or below. Additional tubing, especially hard angles will further reduce the flow. I would suggest you get a flow meter ( you can probably borrow one from a plumber for a day) and test the actual flow rate in your set up. Remember that the chiller will further reduce the flow itself. Odds are good you are closer to the needed 1300 than you think. You can also install a small diverter valve in the line. Basically splitting the output from the pump into two lines. One can carry about 1250 GPH and the other the rest which it just returns to the tank unchilled. Hope that helps MM

Send your message to us

Vibration Pump VMP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords