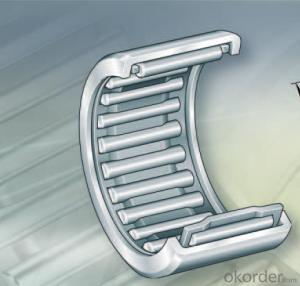

Supply plane thrust needle roller bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A plane bearing, thrust bearing is also called plane needle roller bearings or thrust plane needle roller bearing, thrust bearing radial needle roller bearing has the advantages of compact structure, plane diameter size and load capacity and other types of bearing at the same time, minimum diameter, especially for radial support structure and installation size restricted. The thrust plane needle roller bearings use according to different occasions,can choose the inner ring bearings or needle roller and cage assemblies, the shaft necksurface and the surface of shell holes matched with a bearing directly as bearing inner. The outer rolling surface, in order to maintain the load capacity and operating performance and have the same ring bearing, shaft or housing holes raceway surface the hardness and surface machining accuracy and surface quality shall be similar raceway of the bearing rings. These bearings can only bear radial load. Plane thrust needle roller bearings byplane with a needle or cylindrical roller cage assembly and flat washers. The main types are: AXK/AX/AXW/NTA plane thrust K811/K812/K89thrust cylindrical roller and cage assembly.

Structure

Edit

1 Structure

Bearing

Shim

AXK

Metric thrust needle roller and cage assembly

AS

1mm thick metric dimensions of gaskets

AXW

With stamping stamping center set of thrust needle roller and cage assembly

TRA

The thickness of 0.8mm inch size gasket

AX

With needle roller thrust bearings, control ring

TRB

The thickness of 1.6mm inch size gasket

K811, K812, K893, K894

Thrust roller and cage assembly

51100512005230052400

Thrust ball bearing

NTA

Inch size thrust needle roller and cage assembly

AXK type thrust needle roller and cage assemblies is a main component of thrust needle roller bearing. The holder with cold forming steel plate, the small cages are made from plastic, the high accuracy of G2 grade needle, so as to ensure a uniform load distribution.Thrust cylindrical roller and cage assembly and similar type AXK module, which can endure high thrust load.

The production of imperial thrust needle roller and cage assembly and supporting the use of pads, such as TC, TWA, TWB, TWC series.

AXW type needle roller thrust bearing is composed of a AXK type thrust needle roller andcage assembly components and a stamping center set.

The main components of AX type needle roller thrust bearing is AXK component and the thrust washer, and a control ring two are connected into an integral body.

2 thrust washers

The thrust washer mainly high quality spring steel strip (sheet) stamping, thicknessdepending on customer needs. The washer after quenching - Plastic - polishing. He is mainly used for adjacent parts cannot be quenched, but with sufficient rigidity and geometrical accuracy of the occasion, the support surface should be completely thebearing washer.

The shaft ring WS, ring GS and bearing washer is made of bearing steel LS quenchedentity washer, surface grinding and polishing, outer surface and the inner hole of the shaft ring seat by grinding. Entity washers general and thrust cylindrical roller and cageassemblies.

Type NTA is a British size thrust needle roller bearings, bearing structure and manufacturing process to be more complex than the AXK type.

Use the plane thrust bearing is very extensive: automobile, motor, electrical appliances,machinery, furniture, toys, printer, engineering machinery, sewing machine, packaging machinery, printing machinery, food chemical machinery, machine tools, textile machinery,fitness equipment, electronic products etc..

- Q: The question is For e.g. S47 °W ^How do I convert that to a true bearing??

- Bearings are usually measured clockwise from true north, so S is 180°, and W is clockwise from there, so we would add 47° to 180° to get S47°W has a true bearing of 227°.

- Q: I have 8 bearings like any other skateboard. all 8 are crappy because my bro takes it out in the rain. Damn. And one of the 8 is all smashed up(long story). So im riding to school and when at fast speed it starts to wobble ALOT even on flat smooth ground. Would buying new red bone bearings fix this?thanks

- The bad bearing could be causing a vibration, but probably won't cause the board to wobble. Usually bad bearings make noise and don't roll freely. It sounds like you might be getting speed wobble. This is caused by loose trucks at high speed. You can try tightening up the trucks when you go fast, but be sure to loosen them up for other riding. You might want to check for a blown bushing as this could be causing the wobble problem as well. You can also change your position on the board as well when riding at high speeds. Smaller, narrower boards are more prone to speed wobble than longer wider ones.

- Q: Both the same size rimes both bmx. But one rims bearing don't work good anymore. How can i put in new ones?

- have you tried putting oil or grease on it? have you checked if the axle bolt is screwed down too tight, it might be binding, loosen just a bit and see. or, you might be able to take the old one off, clean it up in some gasoline, grease it back real good and put the same one back in. you can usually tell, if the rollers look good you can use it, if they are all pitted looking the bearing is shot. from Grandpa. I hope you are well.

- Q: DOES IT???

- Yoyo's have bearings? Then they don't work like when I was growing up - how would a bearing unit grab the string to climb it.

- Q: I have a shaft that is in a vertical position. I need to support the axial (vertical) and the radial (side) force. I can understand how to support the side force with the ball bearings. I would just slip the bearings through the shaft and then create some kind of housing and bolt it to a structure close to it. But the radial force? The ball bearings I have do not have any type of set screw, so their is nothing to lock it into place.

- There are pressure bearings which are installed (in your case) at the bottom of a vertical rotating shaft to support the weight or downward pressure of it and reduce friction. Those bearings are usually roller or needle bearings. I have seen them also with steel balls but having an identical top and bottom plate or ring. It is unwise to use regular ball bearings with an inner and outer ring for that.

- Q: what solvents are good for cleaning skateboard bearings?

- Honestly... unless you have very good bearings, the best thing youc an do is toss them and get a new set. Most bearings are inexpensive and rather cheaply made. If you are using something like bones swiss, then take care of them and they can last for years. What do I use to clear my swisses? Gasoline. Its dangerous, but nothing works better. Honestly, just get a new set if you are riding cheap bearings.

- Q: Hi, the question is; A fish swims 2km from point A to point B at a bearing of 30 degrees (measured anticlockwise from due east). It then travels due east to point C for 1km.a) Determine the distance the fish is from its starting point.b) Write vector AB and BC using vector units i and jI drew a diagram, and am completely stumped! thank you in advance! guidance in the right direction is also fine! I just have no idea where to start!

- using compass bearings: (2,60°) + (1,90°) = (2.9093, 69.8961°) - - - - - - (2,60°) = (1.7321, 1) - - - - - - (1,90°) = (1, 0) - - - - - - (1.7321, 1) + (1, 0) = (2.7321, 1) - - - - - - so: a) 2.9093 km b) (1.7321, 1) and (1, 0)

- Q: the lucky titanium bearings must not be 100% titanium because they will be too heavy, are they really 100% titanium or are they an alloy?

- Zenni Optical There are hundreds of 100% pure titanium eyeglasses at affordable prices.

- Q: It kinda makes a humming sound from the front end

- Ball bearings?? There are no ball bearings in the front end of a Ford Explorer, or any other car for that matter. Most cars use tapered roller(drum)bearings. They usually run 10-25$ per side, plus 5-15$ for new seals to put around them. Grease will be about 10$ for a can of good stuff. Do it yourself and save some money on the labor.

- Q: Thru the oil pan on a vortec 350??? In a half ton P/U.

- Ask yourself WHY this need to be done when your engine should last for 300,000 miles WITHOUT needing ANY internal parts. The answer of course is that you have benn using INFERIOR WAX based engine oils. Even now, you PROBABLY do NOT need new bearings, but you DO need an engine flush and switch over to any of the good synthetic oils with a 0 series rating. Your engine life will extend and your bearings will be protected in the coldest weather, even at START_UP, which is where most engine wear actually occurs. TRUST ME, I know!! You shouldn' tneed crank resurfacing, but take the time to platigage the bearings, or have someone who KNOWS what they are doing repair this thing, Usualy a little crocus cloth will clean the crank surfaces perfectly. THINK AHEAD, and LEARN form this experience. USE DEXOS oil of Mobil One or Amsoil in the future. You will save money and your engine sensors and converter will last longest. GOOD LUCK and HAPPY REBUILDING!!!

Send your message to us

Supply plane thrust needle roller bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords