Needle Roller Bearing High Precision Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

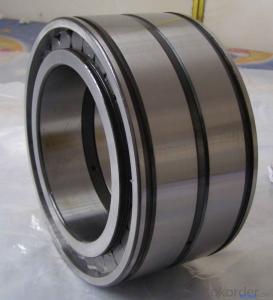

Needle Roller Bearing High Precision

Description

Needle roller bearings are roller bearings with cylindrical rollers that are small in diameter. In spite of their low cross section, needle roller bearings have a high load carrying capacity and are therefore extremely suitable for bearing arrangements where radial space is limited.Radial needle bearings are cylindrical and use rollers parallel to the axis of the shaft. Thrust needle bearings are flat and use a radial pattern of needles.

Feaures

Full compliment bearings have solid inner and outer rings and rib-guided cylindrical rollers. Since these bearings have the largest possible number of rolling elements, they have extremely high radial load carrying capacity and are suitable for particularly compact designs.Needle bearings are heavily used in engine components such as rocker arm pivots, pumps, compressors, and transmissions. The drive shaft of a rear-wheel drive vehicle typically has at least 8 needle bearings (4 in each U joint) and often more if it is particularly long, or operates on steep slopes.

F&Q

Q:How long es cycle of bearing life?

A:According to international standards, at least a year and a half , up tu 2 years

Q:How to maintenance bearing

A:Add to lubricantes on time

Q:Have diagram for bearing

A:The small one no have, large bearings will provide diagram

- Q: i have a small amount of play in both of the front wheel bearings and i just want to know if i can go without buying all new wheel bearings.

- 2005 Ford Explorer Wheel Bearing

- Q: I need to order bearings for the neck of the frame on my bike. I do not know what that piece is called or what i would look for as far as bearings go. Thank you

- Neck okorder /

- Q: are these above, just consumable type things ,that need replacing after time, how many miles for each generally speaking would they need to get replacedwhat are signs that track rod ends have excessive playwhat are signs that wheel bearings have excessive play, and what exactly do they do

- if they bad now the best time to do it since tie rod control s steering breaks you crash wheel bearing control wheel spin breaks wheel locks up or comes off you crash wheel cylinders part of brake system no brakes you crash driving any amount of tiem with any of them bad not smart crashing cost you way more than parts will your car your life few hundred buck notr hard for me to know which id pick fix the car over my life any day of week

- Q: I have a rm 125 and I might need to split the case to make some repairs and I was wonderin if you have to replace all of the bearings and seals when you do it

- No, you don't HAVE to replace all the bearings and seals. When we do bottom end work we split and clean the entire bottom end. Then we decide what seals and bearings to replace. For example, on an RM that was split due to a transmission shift fork problem we would split the cases, remove the gear set, measure all the transmission surfaces and forks, replace what is bad, check the output shaft seal, replace if torn, or leaking, check out the crank bearings and replace if there not smooth and check both crank seals, if they look good under a micro-scope and it ran good when we received the machine then we don't replace them, if they look bad or torn then they get replaced. To answer your question, No, you don't have to but don't be upset when you have to tear it back down cause you missed replacing a $2.00 seal.

- Q: ok, the vegetable oil part was dumb....but i heard u can soak them in alcohol...but how do i re-grease them?

- let okorder / ... and if you ever need tip tricks or a tip trick video you can message him...

- Q: The serpentine belt in my car came off somehow and I found it in the driveway (this was a few days after it had been replaced) and my dad told me to drive my car to the automotive place without it and if it overheated just to pull over, let it cool, and then keep going. it did overheat and I pulled over, but called AAA and had them tow me, now the guy fixing my car told me my alternator bearings have failed, and that it wasn't like that when he did the belt before. Was this from the drive there? or from something else?

- The alternator bearings might be the reason the belt came off in the first place. Or it is a coincidence. Either way, you didn't cause the bearing to go bad, and neither did your mechanic. It just is.

- Q: sealed bearing hubs

- They don't, they are packed with grease before they are assembled together. That's all the grease they get for its lifetime!!!! That's why you don't hold high pressure washer hoses up against them, you can force water into them cause them to fail quicker

- Q: So i took my bearings out of my skateboard to clean, and now i can't get them back in! I know that pounding it dents it, because i tried it before and i ruined my bearings. but its too hard to push them back in with my thumbs, i have the hard wheels. Somebody help me!

- Check okorder /

- Q: Need 3 5/8 closed end bearings.

- Check okorder . They'll have what you need if you can navigate your way through their enormous on-line catalog to find it. You'll need a credit card to place an order. These folks must be the world's largest engineering supply company. You want pillow bearings for a 3 5/8 shaft? They won't be cheap. Why would anyone want a closed end linear bearing -- sounds like an oxymoron. Seems I have more questions than answers.

- Q: I am interested in cleaning my roller blade bearings so that are free of sand.I saw a recommended video to wash the open ball bearings in acetone but I need some help understanding how to get my bearings to run their best.I found some nail polish remover and I am planning to wash the bearings in a small bath unless anyone knows if a more pure formula of acetone might be safer.I'm still doing some research and I found some chemists on the internet mentioned balancing the alcohol to water ratio 1:1 with acetone sort of like with mouth washthey also mentioned that methyl acetate and how it might help to filter it out. I'm wondering I'm now interested in seeing how acetone might react with sand (SiO2) but I'm actually thinking it might just dissolve it.What does everyone else think?Is there a better way to clean bearings? (excluding lube)

- Absolutely none of the liquids you mention will react with SiO2 or dissolve it. There is nothing that will dissolve SiO2 that won't also dissolve your bearings. The point of the various bits of advice is that the acetone (or whatever organic solvent) will dissolve the lubricant in the bearings which is holding the sand grains there. Whether you use nail polish remover, or acetone (diluted or not) or gasoline or kerosene or maybe even alcohol doesn't much matter. (Although in all cases you need to observe the safety precautions about inhalation and fire hazards, and keep the solvent off of the upper parts of your roller blades.) Your goal is to remove all the oil (or whatever lubricates your bearings) then let the bearings dry completely. Then you should be able to remove any left over sand by brushing it out of the bearings with something like a soft brush or blowing it out with compressed air. After all the sand is removed, you need to re-lubricate your bearings. (I've been assuming all along that your bearings are metal. If they are not, you need to be careful about your choice of solvents, lest you dissolve your bearing too.) I doubt there is anything else you can do to remove sand from your bearings. In the long run it's probably easier to find a place to roller blade where there isn't so much sand.

Send your message to us

Needle Roller Bearing High Precision Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords