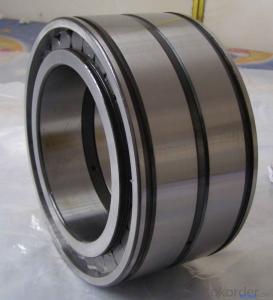

K 18X24X20 Needle Roller Bearing China Supply High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Product | Best Price Needle Roller Bearing K 18X24X20 |

Precision Rating | ABEC1,ABEC3,ABEC5 |

Clearance | C0,C2,C3,C4,C5 is available |

Sealed Cap | Rubber or Metal |

Paypal | Acceptable |

OEM | Accept |

Vibration Level code | V1,V2.V3 |

Material | Gcr15 |

Seals Type | ZZ/ZRS.RZ/RS. Open |

Mass | 0,019kg |

Bore Size | 18 mm |

Outside Diameter | 24 mm |

Hign | 20 mm |

Regular export packing | Plastic drum+White box+ carton |

industrial packaging or as your requirement | |

MOQ | 1 pcs |

Delivery Time | 3-7 days after receiving your payment |

Payment Terms | L/C,T/T,Western Union |

Port of shippment by sea | Shanghai,guangzhou,qingdao |

Place of Origin | China |

Samples | Available |

Product Applications:

Needle roller bearings are mainly used in car engines, transmissions, compressors, cranes, etc.

Product Advantages:

1.Bearing Manufactory ( Have our own technical department)

2.High quality products (Long Life and low noise)

3.Well-daserved Reputation (Good Stock Guarantee)

4.Professional service ( Promptly shippment)

5.OEM Service,Sample is available

Packaging & Delivery

Packaging Details: | 1.industrial packing |

Delivery Detail: | in stock or 15-30days after P.O |

QC:

We have complete process for the production and quality assurance to make sure

our products can meet your requirement. And our quality can compare with the

most chinese famous bearing manufacture. we have the same technology. Such as

1. Assembly

2. Windage test

3. Cleaning

4. Rotary test

5. Greasing and gland

6. Noise inspection

7. Appearance inspection

8. Rust prevention

9. Product packaging

- Q: Give a detailed procedure of maintenance of electric motor bearings and the effects of overgreasing?

- There's a few different thoughts on greasing motors so its subjective mainly in regard to doing it running or not running. A big problem from overgreasing is if the bearing gets pressurized. This will lead to premature failure. Also extra grease can be forced in among the winding which isn't great. Some motors, especially larger ones, have plates to remove so that you can tell grease has made it through and to prevent pressurization. The manufacturer will give you the best guidance on type and amount of grease, procedures etc for their motors. Also be careful if the motor has been worked on so may not have original grease and some greases don't mix well.

- Q: How to replace front wheel bearings and 97 saturn?

- First you break the lug nuts and axle nuts loose, then jack the car up and support on stands. When you have it up on the stands start removing parts, the wheels, calipers, and rotors. That should expose the hub bearing bolts for removal, then take off the main axle nuts. Find and disconnect the traction control wires that lead to the hub bearings, then remove the hub bearing retaining bolts. Then reverse the order to install the new hub bearings, you will need a torque wrench for this job and the axle nut socket. When putting everything back together torque to exact specifications, even the lug nuts because any wrong torque will ruin the new bearings.

- Q: i wasn't to sure how to tell. i didn't think that it mattered but i guess it does. i figured that out when i bought bearings and wheels and they didn't fit inside the wheels. can you please tell me how to tell what kind of bearings i need in this type of situation?

- I think that Thunder Deck is the best skateboard it rocks

- Q: are these above, just consumable type things ,that need replacing after time, how many miles for each generally speaking would they need to get replacedwhat are signs that track rod ends have excessive playwhat are signs that wheel bearings have excessive play, and what exactly do they do

- if they bad now the best time to do it since tie rod control s steering breaks you crash wheel bearing control wheel spin breaks wheel locks up or comes off you crash wheel cylinders part of brake system no brakes you crash driving any amount of tiem with any of them bad not smart crashing cost you way more than parts will your car your life few hundred buck notr hard for me to know which id pick fix the car over my life any day of week

- Q: my home ac unit is blowing warm so had a company come out and look at it. they said the condenser fan motor bearings were shot. I declined replacement but after he left I went on the roof to check it myself but did not notice any looseness or grinding when i spun the blades. How would tech know? would this cause it to blow warm it is a heat pump rooftop unit.

- The service call is generally a 'no cool' call when it comes into the shop, and there are ten things to check to diagnose the no cool problem, more on a h/p, so determining that the blower motor is THE cause isn't very common at all. Better call someone else. The motor test is seeing if the shaft spins freely, does not have a lot of up and down movement and then measuring the volts and amps, with a multimeter, while running. The amperage draw if higher than the run load amp will tell you the condition of the bearings and/or windings. You test the capacitor, too. And the wiring connections. Also, look at the blower wheel. Besides, a problem with the motor that slows down the rpm's and lowers air flow will deliver less return air across the evaporator, which will decrease it's temp from 40 degrees to possibly near freezing, and deliver colder air, not warmer. So the problem is something else. The most common is dirty coils, filters. Then leaks. But, they will have to check the pressures and temps, and see what those tell you and then go from there.

- Q: I recently got a engine block that looks great, 60k on it but I bought a new crankshaft, and upgraded engine parts. MY friend is telling me I don't have to get the block line bored, but to just replace the bearings...is that going to be a problem? new pistons, rings, seals, and crankshaft...used block. Of course I will get the cylinders done but is the main bearing re-bore necessary????thx

- if its in specs i wouldnt get it line honed. a machnist once told me that the only time the is really necissary is either A. it is out of tolerances, or B. You have new main caps installed

- Q: what is the best bearings company for my skateboard?

- get some bones reds their great bearings and only 15 bucks too

- Q: Can I change the camshaft in my small block chevy 350 without changing the cam bearings? The motor is appears fairly fresh.

- I know that there is no way to plasti-gauge the bearings, but do you really want to take that chance? Removal of the old bearings and installing the new ones will take about an hour with the correct tool. Isn't that time well spent to protect your investment? I have put a cam in with out replacing the bearings, but I was selling the car and was trying to cut costs, my bad. It's your decision.

- Q: also if anyone knows are speed demons oiled speed bearings abec 7's sealed or sheilded?

- the okorder

Send your message to us

K 18X24X20 Needle Roller Bearing China Supply High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords