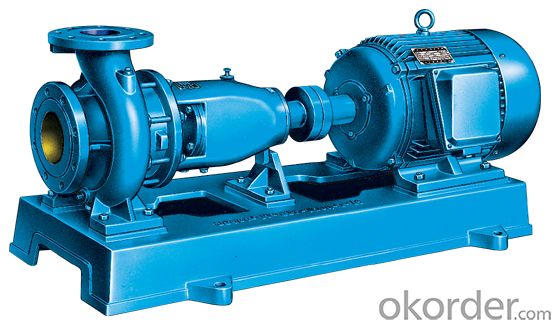

Single Stage End Suction Centrifugal Pump Ga Series

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Single Stage End Suction Centrifugal Pump Ga Series

GA series end suction centrifugal pump completed sets are designed with technical benefits to meet the needs of users in a variety of city water supply, fire fighting, irrigation, and cooling applications.

Design & Material of Single Stage End Suction Centrifugal Pump Ga Series

| Bare Shaft Direct Coupled with Electric Motor or Engine | ||

| Design | Performance and dimensions referring to the European standard BS EN733/DIN24255 | |

| Structure | Horizontal,Axial End-Suction,Single-Stage,Single-Suction,Volute Casing,Back pull-out | |

| DN (mm) | 32 - 250 | |

| Flange | DIN2501 standard,ANSI B16.5 Class 150lb optional | |

| Casing | Cast Iron standard,Ductile Iron,Stainless Steel optional | |

| Impeller | Bronze standard,Cast Iron,Stainless Steel optional | |

| Shaft | ASTM420standard, ASTM304, ASTM316, ASTM1045 optional | |

| Shaft Seal | Mechanical Seal Standard, Gland Packing optional | |

Operating Data of Single Stage End Suction Centrifugal Pump Ga Series

| Flow Rate(Q) | 2-1100 m3/h | |

| Head(H) | 2-152m | |

| Speed | 1450~2900 rpm (50HZ), 1750~3500 rpm (60HZ) | |

| Temperature | -10 Celsius to 105 Celsius | |

| Working Pressure | 1.2 MPa standard, 1.6 MPa on request | |

Applications of Single Stage End Suction Centrifugal Pump Ga Series

1. Heating, ventilation and air-conditioning

2. Fire Protection and Fire Fighting

3. Water circulation

4. Liquid transfer

5. Irrigation

6. Cooling

7. Booster service

- Q: Ac was working fine before the mechanic replaced the water pump. Now the AC only blows hot air. Is this related?

- Ac Water Pump Not Working

- Q: okay i observed and found out my water pump is leaking from a hole in it. after doing research i am told this is where it usually is suppose to leak from. anyway i read instructions for my car(92 fwd celica) and they say people have to remove the fan or something. my pump is under my alternator so i dk what fan they speak of. the only fan i see is by my radiator. all i see is remove the alternator(did it before) and remove the pump. is this correct. help.

- most cars have a fan. if your does not. then proceed.

- Q: i need to know how the water pumps, how it transports, where it goes, and how the structure is used to control the direction of the flow. Please help? I'd really like to know., thank you in advance!

- water pumps have impellers which when rotated mechanically by a motor the water gets pumped up from lower level to a higher level depending upon the speed of rotation.the direction of waterflow is regulated by means of pipe lines which have curved bends to regulate smooth flow of water pumps in different directions. there r many differnt pumps each differs from one another.please vote

- Q: my water pump is leaking and chirping would like to know the procedure

- Disconnect battery ground cable. Drain coolant from radiator. Remove upper fan shroud. Remove drive belt. Remove fan assembly from engine. Lower radiator and heater hose from the water pump. Remove water pump attaching bolts and water pump, Fig. 15 . Reverse procedure to install. Tighten water pump attaching bolts to specifications

- Q: replaced one themostat, disconected lower unit twice look at the water pump everything looks fine but when lower unit was reconnected water pump would not work. not sure if asembled it wrong or forgot to d somthing. can someone help.

- if all is lined up properly use compressed air and blow through the visual. this will dislodge any debris that may be blocking the water passages.

- Q: I need to replace a water pump

- Just take off the fan belt, unbolt the water pump and fit the new one. Make sure the gasket area is clean and use a new gasket. If it has the fan on it, take that off first.

- Q: 2000 3.3L engine. I understand,depending on engine year, it can be a very difficult job. Is this the one or is it much more difficult on the 3.0 L ? One involves timing belt ? Help ? Thanks' Ken

- If there are not any obvious leaks, the 1st factor to envision may be the Radiator/coolant reservoir cap for a lacking gasket or o-ring based at this variety of cap, and if ok, do a tension attempt to work out if the cap is preserving tension. in the journey that your engine has a bleed screw, you ought to use compressed air source (and regulator, if mandatory) to pressurize the engine to particularly below the cap score and than seem for leaks. If none chanced on, a compression examine will point out a a probability blown head gasket.

- Q: Hello online mechanics! You guys have saved me a lot of money on my car, so now I have a new question! I have a 97 Ford Contour and lately since it's been cool in NJ, I've been hearing a tapping coming from the timing belt cover, but when the car warms up, there's no sound. I took the car to my mechanic and he says that I need to have the timing belt replaced, the pulleys adjusted, and the water pump changed. The price for doing the timing belt was $400 (including adjusting the pulleys) and $700 for the timing and the water pump. My question is ; do I need to do the water pump? He says that if you do the timing belt, that you should do the water pump too, but should I if there's nothing wrong with it ( as far as I know) and I'm not looking for the added expense? I thought if it ain't broke don't fix it still applies to things, or am I mistaken? Thanks guys gals! In these tough economic times, I'm not looking to spend any more than is necessary!

- ask some of your friends if they have a mechanic that they trust . Take the car to them and see if you get the same answer ?

- Q: my 2003 dodge durango broke down 6 weeks ago. the mechanic put it on the diagnostic machine, and it said i needed a fuel pump and a water pump. well i got the fuel pump changed and he told me if i kept water in the car it could hold out for a little while until i get the water pump fixed. so i kept water in it it's been 3 weeks. saturday night all of a sudden i watched the temperature gauge jump to HOT! I pulled over and it was smoking like hell. i'm lucky a friend of mine drove by at that instant and went to his house and got me antifreeze and water and put it in the car. so it was fine sunday. then last nightafter i got home it was smoking again. i let it cool down and then filled it up with water. this morning i took my daughter to school and then drove to my other daughter's daycare and it was smoking like crazy and there was antifreeze and water all over the ground where i parked. so i left it at the daycare and got a ride to work. should i fix the water pump? or is

- Chances are if you had a reputable mechanic tell you it needed a water pump at the time, and he's sure it was leaking.... assuming you haven't overheated the engine that caused gaskets to blow (ie. head gaskets), then a water pump should fix the problem. A good quick check is: is there steam coming out of your tail pipe... if so, you've done more damage than what the water pump will take care of.

- Q: I was recently driving and noticed my heat gauge in the red. I have a 1992 Honda Accord 4 door LX. When I opened the hood what appears to be water was all over the place. Is this the water pump or something else? I want to fix it this weekend so I was hoping for a better understanding of what it might be. I am aware of the labor involved with the water pump and removing the timing belts to get to it. Thanks a bunch in advance!

- it should,nt be water, it should be anti-freeze if it was leaking. if you meant anti-freeze the it don,t have to be the pump. it cold be a busted radiator hose, the radiator or 1 of the heater hoses leaking.

Send your message to us

Single Stage End Suction Centrifugal Pump Ga Series

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords