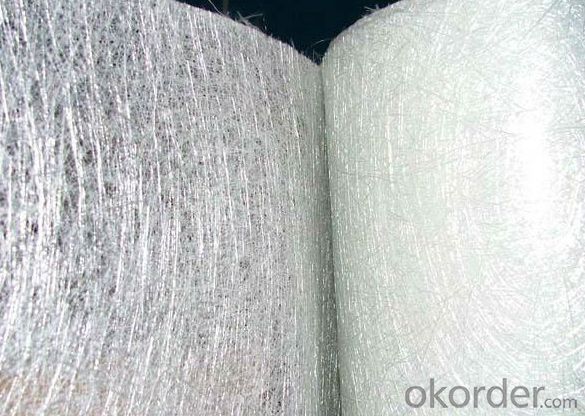

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2500mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 BOX kg

- Supply Capability:

- 1000MT kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Our chopped strand mat is with width 2500mm, packing in wooden box (pallet)with width 2550mm. In each 40HQ can be loaded 16-18 boxes(pallets), qualitu is around 2000kgs in each container.

2.Main Features

Our chopped strand mat factory specializes in manufacturing E-glass Chopped strand Mat (chopped strand mat manufacturer). The products range from chopped strand mat 300g/m2, chopped strand mat 450g/m2 to chopped strand mat 600g/m2 and 900g, the width from 102cm,104cm,125cm to 320cm.

Standard Specifications for Chopped strand mat

1. High quality

2. ISO9001, 2008 quality controled

3. 320cm width, 100g,300g,450gto 900g

3.Specifications

Product code | Glass type | Unite weight (g/m2) | Width(mm) | Roll weight (kg) | Moisture (%) | Binder content (%) |

100 | E Glass | 100+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

150 | E Glass | 150+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

200 | E Glass | 200+/-20 | 200-3200 | 30-70 | <0.2-0.3 |

3-4

|

300 | E Glass | 300+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

| 450 | E Glass | 450+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

600 | E Glass | 600+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

900 | E Glass | 900+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

Package for Big Width Mat:

1, Each roll will be wound on 4 inches paper core, strong enough for the loading and transportation;

2, Each roll of mat will be wrapped by plastic film;

3, 9 Rolls wil be packed in one wooden frame box;

4, Both side closed by polywood;

5, Steel strip is used for fasten the wooden box.

4. FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

1000kgs;

4. Can you provide sample?

Yes, we can offer free sample for you.

5. Payment terms?

Accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

7. What is the Production Lead Time?

1 *40HQ each day, depend on the size of the mat.

- Q:Can fiberglass mat tissue be used for windbreak panels?

- Yes, fiberglass mat tissue can be used for windbreak panels. It is a lightweight and durable material that can provide effective protection against wind and other environmental elements.

- Q:Can fiberglass mat tissue be used for insulation in cleanrooms?

- Fiberglass mat tissue can indeed be used for insulation in cleanrooms. It offers several advantages that make it a suitable choice for such applications. Firstly, fiberglass mat tissue has excellent thermal insulation properties, which helps to maintain the desired temperature and prevent heat transfer in cleanrooms. This is crucial in environments where temperature control is essential for processes or equipment. Additionally, fiberglass mat tissue has good acoustic insulation capabilities, which can help in reducing noise levels within cleanrooms. This is particularly important in cleanrooms where sensitive equipment or experiments are conducted, as minimizing noise disturbances can ensure accurate and reliable results. Furthermore, fiberglass mat tissue is non-combustible, meaning it does not catch fire easily. This adds an extra layer of safety in cleanrooms where flammable materials or volatile substances may be present. The non-combustible nature of fiberglass mat tissue also contributes to its overall durability and longevity. Lastly, fiberglass mat tissue is resistant to moisture, making it suitable for cleanrooms where humidity control is crucial. It does not absorb moisture, preventing the growth of mold or mildew, which can be detrimental to cleanroom environments. Overall, fiberglass mat tissue is a viable option for insulation in cleanrooms due to its thermal and acoustic insulation properties, non-combustible nature, and resistance to moisture. Its use can contribute to maintaining the desired conditions within cleanrooms and ensuring the integrity of processes and equipment.

- Q:Does fiberglass mat tissue require any maintenance?

- Fiberglass mat tissue does not typically require any maintenance once it has been installed. This material is designed to be durable and long-lasting, capable of withstanding various environmental conditions. Unlike other materials, fiberglass mat tissue is resistant to rot, corrosion, and decay, making it a low-maintenance option for many applications. However, it is important to note that proper installation is crucial to ensure the longevity and effectiveness of fiberglass mat tissue. It should be installed according to manufacturer guidelines, ensuring that it is properly bonded and sealed to the surface. This will help prevent any potential issues or damage that may arise from improper installation. In some cases, fiberglass mat tissue may require occasional cleaning to remove any dirt or debris that may accumulate over time. This can be done using mild soap and water, or by following the manufacturer's recommended cleaning instructions. Overall, while fiberglass mat tissue does not require regular maintenance, it is important to address any issues or damages promptly to prevent further deterioration. Regular inspections and necessary repairs should be carried out to ensure the continued performance and longevity of the material.

- Q:Does fiberglass mat tissue require any special surface bonding agents?

- Yes, fiberglass mat tissue often requires special surface bonding agents to ensure proper adhesion and bonding with the substrate. These agents help improve the overall strength and durability of the fiberglass mat tissue when applied to surfaces such as walls, floors, or other structures.

- Q:How does the width of fiberglass mat tissue affect its installation?

- The installation process of fiberglass mat tissue can be influenced by its width. When contemplating the width of fiberglass mat tissue, it is vital to consider the specific demands of the application or project. A broader fiberglass mat tissue can offer numerous benefits during installation. Firstly, it enables a greater coverage area, reducing the number of required overlaps and potentially saving time during installation. This can be especially advantageous in large-scale projects where efficiency is of utmost importance. Moreover, a wider width can provide better overall coverage and minimize the risk of potential gaps or weak points in the installation. This can result in a more consistent and reliable end product, ensuring improved performance and durability. However, it is important to note that a wider fiberglass mat tissue may also present certain challenges during installation. It can be more challenging to handle and maneuver, particularly when working in tight or confined spaces. This may necessitate additional caution and attention to ensure proper alignment and smooth application. Additionally, the width of fiberglass mat tissue can impact the amount of resin or adhesive required for installation. A wider width may necessitate a larger quantity of resin or adhesive, potentially leading to an increase in the overall project cost. Ultimately, the choice of fiberglass mat tissue width should be based on the specific requirements and limitations of the project. Factors such as the size of the installation area, the extent of coverage needed, and the available resources should all be taken into account to determine the most suitable width for the application.

- Q:How is fiberglass mat tissue used in the production of sports equipment?

- Fiberglass mat tissue is widely used in the production of sports equipment due to its unique properties and advantages. This material is a non-woven fabric made from fine glass fibers bonded together with a binder. It has a smooth texture and is lightweight, yet strong and durable. In the production of sports equipment, fiberglass mat tissue is typically used as a reinforcing layer. It helps to enhance the strength and rigidity of the final product, making it more resistant to impact and stress. This is particularly important in sports equipment where durability and performance are crucial, such as in the manufacturing of surfboards, skateboards, snowboards, and tennis rackets. When constructing a surfboard, for example, fiberglass mat tissue is commonly layered over a foam core and then impregnated with epoxy resin. This combination creates a strong and lightweight structure that can withstand the forces exerted by the waves. Similarly, in snowboards and skateboards, fiberglass mat tissue is applied to the wooden core to provide additional strength and stiffness, allowing for better control and responsiveness. Moreover, fiberglass mat tissue is also used in the manufacturing of protective gear like helmets and shin guards. By incorporating this material into the production process, these items can be made more impact resistant and capable of absorbing shocks. This is vital in sports where there is a high risk of injury, as the fiberglass mat tissue acts as a protective layer, dispersing and reducing the force of impacts. Overall, fiberglass mat tissue plays a crucial role in the production of sports equipment by reinforcing structures, enhancing strength and durability, and improving performance. Its lightweight nature combined with its superior mechanical properties makes it an ideal choice for various sporting applications, ensuring athletes can rely on their equipment to perform at their best while minimizing the risk of injury.

- Q:Can fiberglass mat tissue be used for insulation in underground pipelines?

- Yes, fiberglass mat tissue can be used for insulation in underground pipelines. Fiberglass mat tissue is known for its excellent thermal insulation properties and is commonly used in various industrial applications, including underground pipelines. It provides insulation by preventing heat transfer between the pipeline and the surrounding environment, thus helping to maintain the desired temperature inside the pipeline. Additionally, fiberglass mat tissue is resistant to moisture, chemicals, and corrosion, making it an ideal choice for underground applications where pipelines are exposed to harsh conditions. Overall, fiberglass mat tissue is a reliable and effective insulation material for underground pipelines.

- Q:Can fiberglass mat tissue be used for flooring applications?

- No, fiberglass mat tissue is not typically used for flooring applications. It is commonly used in industries such as automotive, construction, and marine for insulation, reinforcement, and insulation purposes. Flooring applications usually require different materials such as tiles, hardwood, laminate, or vinyl.

- Q:Can fiberglass mat tissue be used for insulation in power generation facilities?

- Yes, fiberglass mat tissue can be used for insulation in power generation facilities. Fiberglass mat tissue is a versatile material that is commonly used for insulation purposes due to its excellent thermal and electrical insulation properties. It is resistant to high temperatures and can effectively trap and prevent the transfer of heat, making it suitable for use in power generation facilities where heat management is crucial. Additionally, fiberglass mat tissue is lightweight, easy to install, and offers high durability and longevity, making it a cost-effective choice for insulation in power generation facilities.

- Q:What are the common sizes available for fiberglass mat tissue?

- The common sizes available for fiberglass mat tissue vary, but typically range from 1.27 meters (50 inches) to 2.54 meters (100 inches) in width, and can be customized to desired lengths by manufacturers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2500mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 BOX kg

- Supply Capability:

- 1000MT kg/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords