China Jushi Fiberglass Chopped Strand Mat Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

China Jushi Fiberglass Chopped Strand Mat Supplier

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

1. Uniform density ensures consistent fiberglass content and mechanical properties of the composites products.

2. Uniform powder distribution ensures good mat integrity, little loose fibers and small roll diameter.

3. Excellent flexibility ensures good mold ability with no spring back at sharp angles.

4. Fast and consistent wet-out speed in resins and rapid air lease reduce resin consumption and production cost and enhances productivity and mechanical properties of the end products.

5. The composite products have high dry and wet tensile strength and good transparency.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

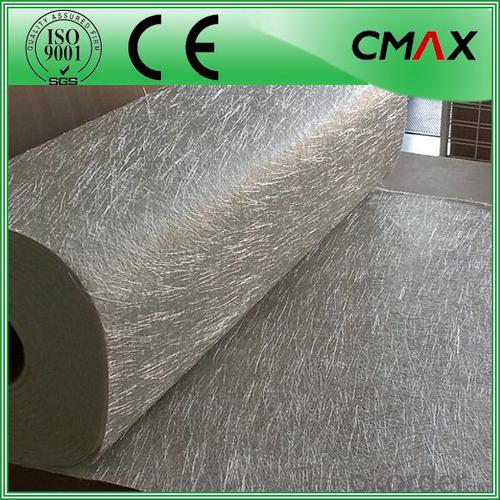

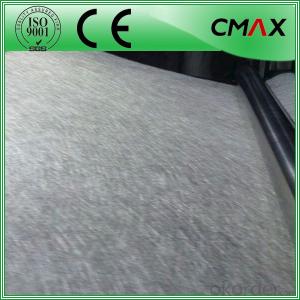

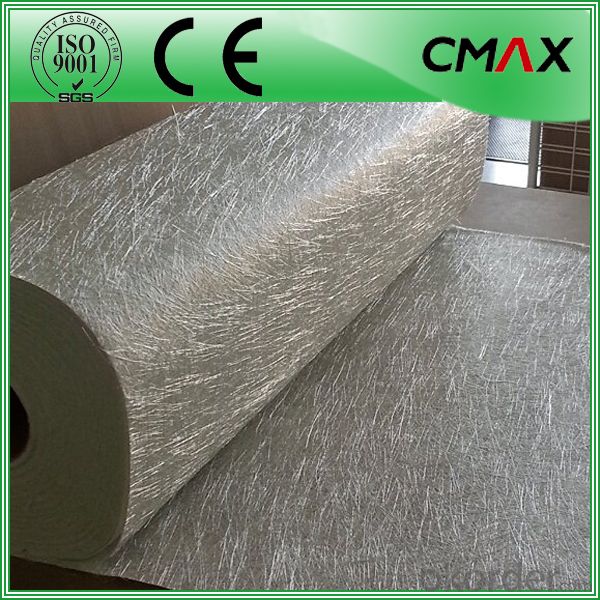

Products Shows:

Certificates:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton.

- Q: This question asks for a comparison between black fiberglass tissue and other nonwoven materials, focusing on their characteristics and applications.

- <p>Black fiberglass tissue is a type of nonwoven material known for its high strength, durability, and resistance to heat and chemicals. Compared to other nonwoven materials such as polyester, polypropylene, and cellulose, black fiberglass tissue offers superior thermal insulation and sound absorption properties. It is often used in applications where these characteristics are crucial, such as in construction, automotive, and aerospace industries. While other nonwoven materials may be lighter or more cost-effective, black fiberglass tissue stands out for its ability to withstand harsh conditions and provide long-lasting performance.</p>

- Q: This question asks about the methods used by manufacturers to maintain the quality of black fiberglass tissue during the manufacturing process.

- <p>Manufacturers ensure the quality of black fiberglass tissue during production through several key steps. They start with high-quality raw materials, such as virgin glass fibers and resins, to ensure strength and durability. They also implement strict quality control measures, including regular testing of the tensile strength, flexibility, and uniformity of the fibers. Advanced manufacturing techniques, such as precision weaving and controlled resin application, are used to maintain consistency in the product. Additionally, environmental controls like temperature and humidity regulation are maintained to prevent variations in the material properties. Finally, post-production inspections and testing are conducted to verify that the final product meets all quality standards before it is released to the market.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other insulation materials, focusing on their properties and performance.

- <p>Black fiberglass tissue is a type of insulation material known for its durability and resistance to heat and moisture. Compared to other insulation materials, it offers a good balance of thermal resistance and affordability. It is lighter than many alternatives, such as mineral wool, and easier to handle, which can reduce installation time and costs. However, it may not provide the same level of sound absorption as materials like cellulose or mineral wool. Additionally, black fiberglass tissue can be less environmentally friendly due to its production process and may not be as effective in certain temperature extremes compared to rigid foam insulations. Overall, the choice between black fiberglass tissue and other insulation materials depends on specific project requirements, including budget, thermal performance needs, and environmental considerations.</p>

- Q: Explain the distinction between black and white fiberglass tissue, including their composition and potential applications.

- <p>Black and white fiberglass tissue are both made from glass fibers, but they differ in color and certain properties. Black fiberglass tissue typically contains carbon black, which provides UV protection and can improve the material's resistance to weathering. It is often used in applications where durability and resistance to sunlight are important, such as in the construction of boats and outdoor structures. White fiberglass tissue, on the other hand, does not contain carbon black and is generally used in applications where aesthetics are a priority, such as in the automotive and aerospace industries. It is also used in situations where the absence of color is beneficial, such as in the production of translucent composites.</p>

- Q: Is it possible to use black fiberglass tissue in the construction or decoration of furniture?

- <p>Yes, black fiberglass tissue can be used for furniture. It is known for its strength, durability, and resistance to corrosion, making it suitable for various applications in furniture design. Fiberglass is often used in outdoor furniture, such as patio sets, due to its weather-resistant properties. It can also be used in modern and contemporary furniture designs for its sleek, matte finish and ability to be molded into various shapes. However, it's important to ensure that the fiberglass is properly treated and finished to avoid any health or safety concerns related to its raw form.</p>

- Q: Can black fiberglass paper be utilized as a material for flooring?

- <p>Black fiberglass paper is not typically used for flooring materials. It is primarily used for insulation and as a reinforcement material in various applications due to its heat resistance and strength. Flooring materials usually require different properties, such as durability, resistance to wear, and comfort underfoot. Common flooring materials include wood, laminate, vinyl, and ceramic tiles, which are designed to withstand foot traffic and provide a comfortable surface for walking.</p>

- Q: Is it possible to utilize black fiberglass tissue for creating insulation materials suitable for homes in cold climates?

- <p>Yes, black fiberglass tissue can be used for making insulation materials for homes in cold climates. Fiberglass insulation has excellent thermal resistance properties, which help in retaining heat within buildings. The color of the fiberglass does not significantly affect its insulating capabilities. However, it's important to ensure that the fiberglass insulation is properly installed and has a high R-value to maximize its effectiveness in cold climates.</p>

- Q: This question asks for the distinguishing characteristics of black fiberglass tissue compared to other fiberglass products.

- <p>Black fiberglass tissue is a specific type of fiberglass product that is treated with a black pigment to provide UV resistance and aesthetic appeal. It is often used in applications where a black finish is desired or where it's exposed to sunlight for extended periods. In contrast, other fiberglass products may come in various colors or be clear, and they can be used for a wider range of applications, including insulation, reinforcement in composite materials, and electrical applications. The main difference lies in the appearance and specific performance attributes, such as UV protection, which is enhanced in black fiberglass tissue due to the pigmentation.</p>

- Q: What distinguishes black fiberglass from other fiberglass types?

- <p>Black fiberglass is a specific type of fiberglass that is dyed black, which gives it a distinct appearance and makes it suitable for applications where a darker color is desired. Other types of fiberglass can be clear, white, or colored, depending on the application and aesthetic preferences. The primary difference is in the color and possibly the additives used to achieve the color. Functionally, they all serve the same purpose of reinforcing materials, providing strength and stability, but the choice of color can affect heat absorption, visibility, and the overall look of the final product.</p>

- Q: Is it possible to utilize black fiberglass tissue as a material for filtration purposes?

- <p>Yes, black fiberglass tissue can be used as a filtration media. It is known for its high tensile strength and resistance to chemicals, making it suitable for various filtration applications. Black fiberglass tissue is often used in air and liquid filtration systems due to its ability to withstand high temperatures and resist corrosion. However, it's important to consider the specific requirements of the filtration system, such as temperature and chemical compatibility, to ensure the black fiberglass tissue is the appropriate choice.</p>

Send your message to us

China Jushi Fiberglass Chopped Strand Mat Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords