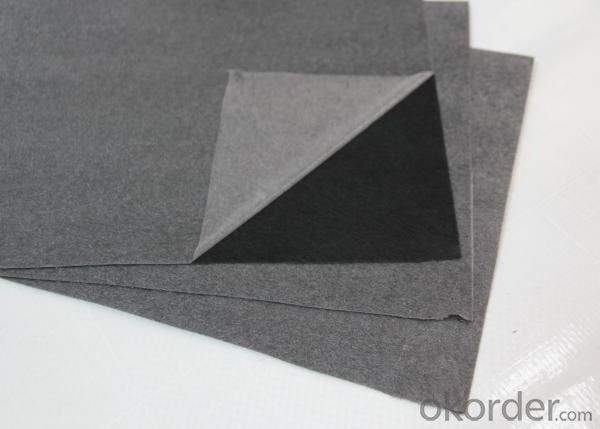

Fiberglass Facing Black Fiberglass Cloth BFC-001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 50000M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification of Black Fiberglass Cloth BFC-001

|

Specification | ||

|

ITEM |

UNIT |

VALUE |

|

Weight of the tissue |

g/m2 |

65 |

|

Weight of the Finished Product |

g/m2 |

65 +25 PE |

|

Thickness |

mm |

0.42 |

|

Fusion Temperature |

℃ |

≦130 |

|

Oxygen Index Number |

% |

≥32 |

|

Tensile Strength MD |

n/5cm |

125 |

|

Tensile Strength CMD |

n/5cm |

105 |

SIZE:

Width: 0.6m---1.3m

Length: 100m-1000m

Core I.D.: 3"(76mm ±1)

Based on order, special sizes are also available.

MSDS:No harm for body and environment, non-volatile product.

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: ±0.5%.

3. The products should be stored at room temperature, kept from wet and kept away heat source.

4. Good appearance without stain, oxidation, mildew.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

2. Application of Black Fiberglass Cloth BFC-001

Fiberglass facing is good at fireproof, mildew resistant, damp proof and strong air permeability. After laminated with glass wool or rock wool, the physical properties is excellent such as hat preservation, noise elimination, fire retardant, extinction,etc.

3. Packaging & Delivery of Black Fiberglass Cloth BFC-001

Depends on the clients' requirements and the production conditions.

- Q: This question asks for environmentally friendly methods to dispose of old black fiberglass tissues.

- <p>To dispose of old black fiberglass tissues without harming the environment, follow these steps: First, check your local waste disposal regulations as they may have specific guidelines for hazardous materials. If fiberglass is considered hazardous in your area, contact a professional waste disposal service that specializes in hazardous waste. If not, you can dispose of it in a designated landfill or recycling facility. Avoid burning the tissues as it can release toxic fumes. Always handle the tissues with gloves to protect your skin and avoid inhaling fibers. Encourage recycling when possible, as this can reduce the environmental impact.</p>

- Q: This question asks about the methods used by manufacturers to maintain the quality of black fiberglass tissue during the manufacturing process.

- <p>Manufacturers ensure the quality of black fiberglass tissue during production through several key steps. They start with high-quality raw materials, such as virgin glass fibers and resins, to ensure strength and durability. They also implement strict quality control measures, including regular testing of the tensile strength, flexibility, and uniformity of the fibers. Advanced manufacturing techniques, such as precision weaving and controlled resin application, are used to maintain consistency in the product. Additionally, environmental controls like temperature and humidity regulation are maintained to prevent variations in the material properties. Finally, post-production inspections and testing are conducted to verify that the final product meets all quality standards before it is released to the market.</p>

- Q: What are the potential drawbacks of using fiberglass facing?

- There are several potential drawbacks of using fiberglass facing in various applications. Firstly, one major drawback is the health hazards associated with fiberglass. Fiberglass is made up of tiny glass fibers that can easily become airborne when disturbed. Inhaling these fibers can cause respiratory issues, skin irritations, and even long-term health problems such as lung diseases. Therefore, proper safety precautions, including wearing protective clothing and masks, need to be taken when working with fiberglass. Another drawback is the potential for fiberglass to degrade over time. Exposure to extreme heat or sunlight can cause the fiberglass to become brittle and crack. This can lead to reduced insulation properties and decreased durability of the material. Additionally, fiberglass is susceptible to moisture absorption, which can cause it to deteriorate and lose its effectiveness. Furthermore, fiberglass facing may not be as effective in certain applications compared to alternative materials. For example, fiberglass may not provide sufficient insulation in areas with high humidity or where there is a risk of water leakage. In these situations, other materials such as foam or foil-faced insulation may be more suitable. Additionally, fiberglass facing can be more expensive than other options. While fiberglass itself is relatively affordable, the cost of installation and maintenance can be higher due to the need for specialized equipment and safety measures. This can make fiberglass facing less cost-effective, especially for smaller projects or those on a tight budget. Lastly, fiberglass facing can be challenging to work with. The material is rigid and can be difficult to cut, shape, and install properly. It requires specific tools and expertise to handle fiberglass effectively, which may limit its accessibility for DIY enthusiasts or inexperienced individuals. In summary, the potential drawbacks of using fiberglass facing include health hazards, degradation over time, limited effectiveness in certain applications, higher costs, and the difficulty in working with the material. It is essential to carefully consider these factors before deciding to use fiberglass facing and to ensure proper safety measures are in place when working with this material.

- Q: What are the standard specifications or criteria that define the quality of black fiberglass tissue?

- <p>Yes, there are standards for the quality of black fiberglass tissue. These standards typically include specifications for tensile strength, elongation, thickness, and other physical properties. The quality is often determined by adherence to industry standards such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). These standards ensure consistency, reliability, and performance of the fiberglass tissue, which is crucial for applications in various industries such as construction, automotive, and aerospace. Compliance with these standards is verified through testing and certification processes.</p>

- Q: Is the use of black fiberglass tissues safe in residential or commercial settings without taking any specific safety measures?

- <p>While black fiberglass tissues can be used in homes or businesses, it's important to take necessary precautions. Fiberglass is made of fine glass fibers that can be inhaled and may cause irritation to the skin, eyes, and respiratory system. Always wear protective gear such as gloves, goggles, and a mask when handling fiberglass. Ensure proper ventilation to avoid inhaling fibers and clean up carefully to prevent the spread of fibers around the area. Consult material safety data sheets (MSDS) for specific safety instructions related to the product you are using.</p>

- Q: This question asks for a comparison between domestic and imported black fiberglass tissue, highlighting their differences.

- <p>The differences between domestic and imported black fiberglass tissue can be attributed to several factors. Domestic black fiberglass tissue is often more affordable due to lower production costs and is readily available in the local market. It may also be more tailored to local standards and requirements. Imported black fiberglass tissue, on the other hand, is usually of higher quality and may offer advanced features not found in domestic versions. It is often sourced from countries with advanced manufacturing capabilities and stringent quality control processes. However, it comes with higher costs due to import taxes and shipping fees. Additionally, imported products may have longer lead times for delivery. Both types have their advantages and disadvantages, and the choice between them depends on specific project requirements, budget, and quality expectations.</p>

- Q: This question asks for the methods to clean and maintain black glass fiber cloth.

- <p>To clean and maintain black glass fiber cloth, follow these steps: 1. Use a soft brush or vacuum cleaner with a brush attachment to remove loose dirt and dust. 2. For stubborn stains, mix a mild detergent with warm water and gently dab the affected area with a soft cloth. Avoid rubbing or scrubbing as it may damage the fibers. 3. Rinse the area with clean water and pat dry with a soft towel. 4. Avoid using harsh chemicals, bleach, or high heat, as they can degrade the fibers. 5. Regularly inspect the cloth for signs of wear and tear, and replace it if necessary to maintain its performance and appearance.</p>

- Q: Is it possible to use black fiberglass paper for the interior of a car?

- <p>Yes, black fiberglass paper can be used for car interiors. It is a durable and heat-resistant material that can be used for various interior applications such as lining the trunk, under the hood, or as a protective layer on the floor. However, it's important to ensure that the fiberglass paper is of high quality and properly installed to avoid any potential issues with durability or safety. Always follow the manufacturer's guidelines and consider professional installation for best results.</p>

- Q: Is it possible to utilize black fiberglass tissue within the interior of a car?

- <p>Yes, black fiberglass tissue can be used in car interiors. It is known for its strength, durability, and lightweight properties, making it suitable for various interior applications such as decorative panels, structural components, and even certain types of trim. However, it's important to ensure that the material meets safety standards and is properly treated for any potential health concerns related to fiber exposure.</p>

- Q: Is it possible to utilize black fiberglass tissue as a material for soundproofing purposes?

- <p>Yes, black fiberglass tissue can be used for soundproofing materials. It is known for its excellent sound absorption properties due to its porous structure, which allows it to trap and dampen sound waves. Fiberglass is also resistant to heat and moisture, making it a durable choice for various applications. However, it's important to note that while it can help reduce noise, it may not provide complete soundproofing. Proper installation and additional layers or materials may be necessary to achieve the desired level of sound reduction.</p>

1. Manufacturer Overview

| Location | Jangsu, China |

| Year Established | 1999 |

| Annual Output Value | Above US$0.3 billion |

| Main Markets | 0.00% Mid East 15.00% Northern Europe 15.00% North America 10.00% Eastern Asia 20.00% Africa 0.00% Eastern Europe 20.00% Southeast Asia 0.00% Oceania 0.00% Western Europe 0.00% Southern Europe 0South east asia;North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fiberglass Facing Black Fiberglass Cloth BFC-001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 50000M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords