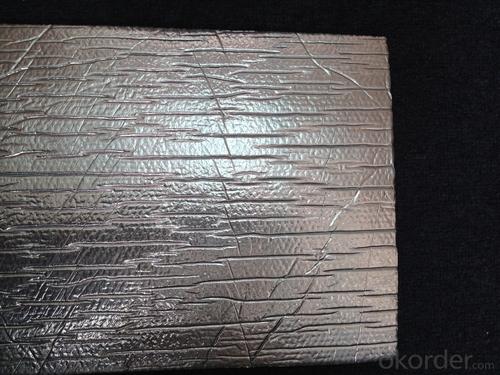

Flexible Ducts Bubble Foil Green Insulation with Fiberglass Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: Does fiberglass facing require regular maintenance?

- No, fiberglass facing does not require regular maintenance. Fiberglass is a durable material that is resistant to many environmental factors, such as moisture, UV rays, and pests. It does not rust, rot, or decay like other materials, which means it does not need to be painted or sealed regularly. However, it is important to keep the fiberglass facing clean and free from dirt or debris to maintain its appearance and performance. Regular cleaning with a mild detergent and water should be sufficient to keep it in good condition. Additionally, if any damage or cracks occur in the fiberglass facing, it should be repaired promptly to prevent further issues. Overall, fiberglass facing is a low-maintenance option that can last for many years with minimal care.

- Q: Is it possible to utilize black fiberglass tissue for the production of insulation materials?

- <p>Yes, black fiberglass tissue can be used to make insulation materials. It is a type of non-woven fabric made from glass fibers that are coated with a phenolic resin. This material is known for its excellent insulating properties, resistance to heat and electricity, and durability. It is commonly used in applications requiring thermal and acoustic insulation, such as in construction, automotive, and aerospace industries. However, it's important to note that proper safety measures should be taken when handling fiberglass due to its potential health risks if inhaled or if skin comes into prolonged contact.</p>

- Q: Explain the distinction between black and white fiberglass tissue, including their composition and potential applications.

- <p>Black and white fiberglass tissue are both made from glass fibers, but they differ in color and certain properties. Black fiberglass tissue typically contains carbon black, which provides UV protection and can improve the material's resistance to weathering. It is often used in applications where durability and resistance to sunlight are important, such as in the construction of boats and outdoor structures. White fiberglass tissue, on the other hand, does not contain carbon black and is generally used in applications where aesthetics are a priority, such as in the automotive and aerospace industries. It is also used in situations where the absence of color is beneficial, such as in the production of translucent composites.</p>

- Q: Is it possible to use black fiberglass tissue as an insulating material within walls?

- <p>Yes, black fiberglass tissue can be used for insulation in walls. It is a type of fiberglass insulation that is often used in residential and commercial buildings due to its effectiveness in reducing heat transfer and providing thermal insulation. Black fiberglass tissue is made from glass fibers and has a high resistance to heat flow, which helps to maintain a comfortable temperature inside the building. It is also known for its durability and resistance to moisture, making it a popular choice for wall insulation. However, it's important to follow proper installation procedures and safety precautions to ensure the insulation's effectiveness and to protect against potential health risks associated with fiberglass.</p>

- Q: Is it possible to use black fiberglass tissue as a material for painting?

- <p>Yes, black fiberglass tissue can be used for painting, but it requires specific preparation. The surface needs to be properly sanded and primed to ensure paint adhesion. Fiberglass is a composite material and can be challenging to paint due to its smooth and non-porous nature. Using a primer designed for plastics or fiberglass can help the paint bond better. Additionally, the choice of paint is crucial; acrylic or epoxy-based paints are often recommended for their durability and adhesion properties on fiberglass.</p>

- Q: How does fiberglass facing compare to other types of insulation materials?

- Fiberglass facing is widely chosen as an insulation material for its many advantages compared to other options. Primarily, it excels in thermal insulation, effectively maintaining a comfortable temperature indoors by minimizing heat transfer. With its high R-value, it offers substantial resistance to heat flow. Moreover, fiberglass facing boasts exceptional durability, ensuring its insulating properties remain intact over time. This longevity also makes it impervious to moisture, mold, and pests, common issues faced by other materials like cellulose or foam. Furthermore, the ease of installation sets fiberglass facing apart, reducing both time and labor costs. It comes in various forms, such as batts, rolls, or loose-fill, adapting to different applications and spaces. Its lightweight nature facilitates hassle-free handling and maneuvering during installation. Another standout characteristic of fiberglass facing is its fire resistance. It is non-combustible, meaning it does not contribute to the spread of fire and can aid in containing it. This feature renders it a safer choice compared to flammable options like foam. Lastly, fiberglass facing is environmentally friendly. It is manufactured from natural materials like sand and recycled glass, minimizing its impact on the environment. Additionally, fiberglass insulation assists in conserving energy and reducing carbon emissions by enhancing the energy efficiency of buildings. Overall, fiberglass facing emerges as an excellent insulation choice due to its thermal insulation properties, durability, ease of installation, fire resistance, and eco-friendliness. It surpasses many other materials in insulation performance, making it the preferred option for diverse construction and insulation projects.

- Q: This question asks for the duration or period of time that black fiberglass tissue can last or remain functional.

- <p>The lifespan of black fiberglass tissue can vary significantly based on its application and environmental conditions. In general, when properly maintained and not exposed to extreme conditions, black fiberglass tissue can last for several years, often ranging from 5 to 15 years. However, factors such as UV exposure, moisture, and physical wear can reduce its lifespan. It's important to note that the quality of the fiberglass and the specific manufacturing process can also impact its durability.</p>

- Q: What distinguishes black fiberglass tissue from other types of tissues in terms of color, material, and usage?

- <p>Black fiberglass tissue is a type of non-woven fabric made from black fiberglass fibers, known for its high tensile strength, heat resistance, and chemical stability. It differs from other tissues primarily in color, as most tissues are white or natural-colored. Additionally, black fiberglass tissue has unique properties such as resistance to UV light, making it suitable for outdoor applications. It's often used in construction, automotive, and electrical insulation, whereas other tissues might be used for cleaning, medical purposes, or as a base for hygiene products.</p>

- Q: What are the uses of black fiberglass tissue in the construction industry?

- <p>Black fiberglass tissue, also known as black glass fiber cloth, is widely used in construction for its heat resistance, strength, and durability. It is commonly used as a reinforcement material in cementitious materials, such as in the production of GRC (Glass Reinforced Concrete) panels and other composite materials. It can also be used as a fire-resistant barrier in walls and ceilings, and for insulation purposes. Additionally, it is employed in the creation of lightweight and strong structures, such as in the construction of roofs and facades, due to its high tensile strength and low weight.</p>

- Q: Can fiberglass facing be used in high-temperature applications?

- Using fiberglass facing in high-temperature applications is not possible. Fiberglass is a reinforced plastic material, renowned for its remarkable thermal insulation and resistance to corrosion. Nonetheless, it possesses a low melting point, rendering it unsuitable for high-temperature settings. High temperatures can cause fiberglass to melt, distort, or deteriorate, thereby jeopardizing its structural soundness and insulation capabilities. To guarantee safety and achieve optimal performance, it is crucial to select alternative materials explicitly engineered for high-temperature environments, such as ceramic fiber or metal facing.

Send your message to us

Flexible Ducts Bubble Foil Green Insulation with Fiberglass Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords