Green Aluminum Foil

Green Aluminum Foil Related Searches

Eco Friendly Aluminum Foil Recycled Aluminum Foil Aluminum Paper Foil Golden Aluminum Foil Foil Aluminum Sustainable Aluminum Foil Food Aluminum Foil Glad Aluminum Foil Recycling Aluminum Foil Reusable Aluminum Foil Yellow Aluminum Foil Reinforced Aluminum Foil Red Aluminum Foil Aluminum Foil Recyclable High Quality Aluminum Foil Grow Light Aluminum Foil Aluminum Foil Tree Sealed Aluminum Foil Aluminum Gold Foil Biodegradable Aluminum Foil Royal Aluminum Foil Thin Aluminum Foil Buy Aluminum Foil Transparent Aluminum Foil Grease Aluminum Foil Aluminum Foil Recycle Aluminum Foil Foam Aluminum Foil For Packaging Cast Iron Aluminum Foil Food Packaging Aluminum FoilGreen Aluminum Foil Supplier & Manufacturer from China

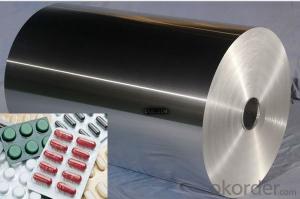

Green Aluminum Foil is a versatile product that is widely recognized for its high-quality and durability. This eco-friendly material is crafted from recycled aluminum, making it an excellent choice for various applications where a sustainable option is desired. Its unique green color not only adds a touch of aesthetics but also serves as a distinguishing feature in various industries.The application and usage scenarios of Green Aluminum Foil are extensive, ranging from food packaging and insulation to arts and crafts. Its lightweight and malleable properties make it ideal for wrapping food items, ensuring freshness and protection from external elements. Additionally, it is used in construction and electrical industries for insulation purposes, providing a reliable barrier against heat and moisture. In the world of arts and crafts, Green Aluminum Foil is a popular choice for creating decorative items and sculptures, thanks to its vibrant color and ease of manipulation.

Okorder.com is a reputable wholesale supplier of Green Aluminum Foil, boasting a large inventory that caters to the diverse needs of customers across different sectors. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Green Aluminum Foil they provide meets the highest industry standards. This makes them a trusted source for businesses and individuals seeking a reliable and sustainable aluminum foil solution for their specific requirements.

Hot Products