Aluminum Composite Foil High Strength Lightweight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

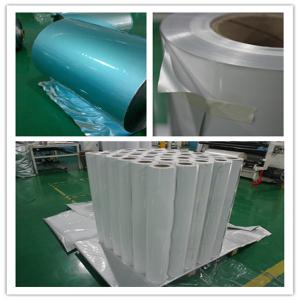

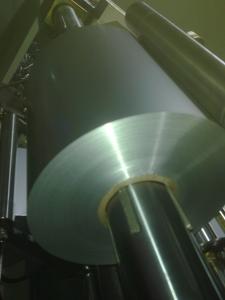

Aluminum Composite Foil is a composite material made by bonding aluminum foil with other materials such as plastic or paper. It is widely used in packaging, construction, electronics, and other fields. By combining the properties of aluminum foil and the characteristics of other materials, aluminum composite foil enhances overall performance.

Main Features:

High Strength: Compared to pure aluminum foil, it has higher strength and toughness.

Lightweight: It has a low density, making it lightweight and easy to transport and install.

Corrosion Resistance: Aluminum has excellent corrosion resistance, and the composite material can further enhance this property.

Good Thermal and Acoustic Insulation: Provides excellent thermal and acoustic insulation, suitable for construction and home decoration.

Easy to Process: It can be processed through cutting, bending, stamping, and other methods to meet various application needs.

Advantages:

Versatility: Can combine the advantages of multiple materials, such as the moisture resistance of aluminum, the sealing properties of plastic, and the printability of paper, to meet various packaging needs.

Cost-Effective: Compared to pure aluminum foil, aluminum composite foil is more cost-effective.

Environmentally Friendly: Aluminum composite foil can be recycled, reducing environmental pollution and resource waste.

Aesthetic Appeal: The surface of aluminum composite foil can be decorated through various treatments such as printing, embossing, and coating, enhancing the product's appearance.

Wide Application: Widely used in food, pharmaceuticals, construction, electronics, and other fields, with broad market prospects.

Applications:

Food Packaging: Extensively used in food packaging, such as chocolate wrappers, beverage pouches, and pharmaceutical packaging, providing excellent sealing and preservation.

Construction Materials: Used in building exterior wall decoration, roof insulation materials, etc., offering thermal insulation.

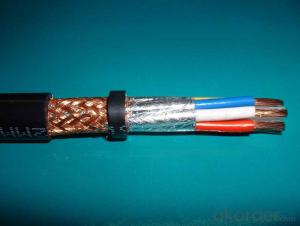

Electronic Products: Used in electronic products as shielding materials and heat dissipation materials, providing good electromagnetic shielding and heat dissipation.

Specification:

PROPERTIES | UNIT | VALUE | TEST METHOD |

| Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength | N/15mm | 13.5 | ASTM D882 |

| Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C-130°C | No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM C1263 |

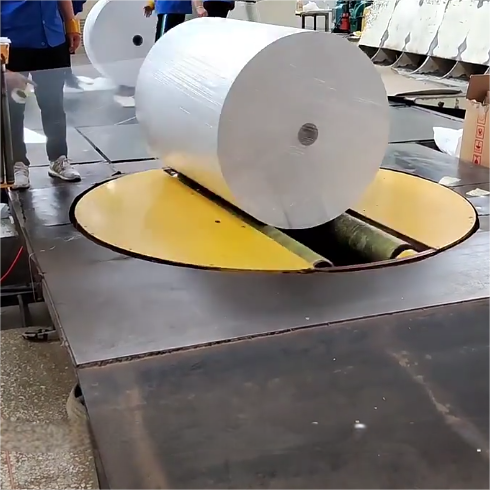

Images:

FAQ:

We have organized several common questions for our clients, may help you sincerely:

1) Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

2)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3)How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: The existing engineering air conditioning pipe aluminum foil glass wool insulation requirements, supervision and protection layers, with glass cloth as a protective layer. Please follow mandatory specifications,

- I think we can find reasons from the following aspects:1, to see how the requirements of the construction drawings, if foil glass wool board clear, no mention of glass cloth, according to the drawings without error, the need to increase it, Party Supervision approval, plus the money!2, to find manufacturers to communicate, so that manufacturers show that aluminum foil, glass, cotton foil foil is the protective layer, do not need to increase other protective layer.3, the design and owners to come in to see their views. Such as glass cloth protective layer do not mention on the design drawings, design will speak for you, otherwise it would be his design errors.4, check list and owner bidding documents, to see the list of project features and bidding documents technical requirements, how to write?.

- Q: How many degrees of aluminum foil can burn?

- The surface does not handle 500 degrees Celsius, if has the coating, the anode oxidation and so on, good nearly 1000 degrees will not burn.

- Q: What is a composite aluminum foil molded poly vinyl foam board, and what is a composite aluminum foil extrusion poly vinyl vinyl insulation board, the two how to distinguish?Please try to be more specific

- 2, insulation performance EPS 0.041, XPS 0.030, indicating that in the same thickness, XPS insulation performance better, or to achieve the same insulation effect, thinner thickness3, water absorption rate EPS, water absorption rate is higher than XPS, XPS almost no water absorption

- Q: I heard that using aluminum foil and salt to add water can make the silver ring bright. Who told me what aluminum foil is and where can I buy it?

- Aluminum foil paper is made from aluminum foil backing paper and aluminum foil paper bonding paper. Soft, easy to change, such as paper, and does not rebound after deformation. The utility model can be characterized in that the utility model has the advantages of ensuring shading, no falling, no light transmission, no pollution, and low price. Aluminum foil paper as an industrial raw and auxiliary materials, products are mainly used in packaging, protection, daily necessities, buildings and so on. The initial development of Hebei Langfang Dacheng is a common type of application in construction, and is mostly used in industrial buildings. It should conform to the application type and basic requirements of auxiliary building materials. Production began in 1932 and the test was successful. Aluminum foil is a new type of industrial material. Will replace more single material, widely used in a variety of flexible packaging. With economic development, China will become the world's most important packaging demand market. Aluminum foil packaging development prospects are very broad.

- Q: Where are the aluminum foil lunch boxes used?

- They are aluminium foil, some restaurants, takeout packages, barbecue boxes, and some baking shops

- Q: Do the aluminum foil used in the electric oven have the right and negative sides?

- In fact, aluminum foil is not only positive and negative sides, the reason why there is a gloss surface and matte surface distinction,Because the aluminum foil is in the manufacture process, is two, two manufacture.

- Q: The aluminum foil I bought reads, "microwave ovens, be sure to refer to the microwave oven instructions."".My microwave oven has barbecue. With foil wrapped in meat into the microwave oven, how should operate? Is that all right? With a microwave or a light wave?

- Microwave oven using skills:1, the use of aluminum foil. Other parts of the corner pointed wings, chicken or fish head, tail or cake too easy to cook, cover with aluminum foil wrap can achieve the purpose of cooking evenly.2. Use of vessel cover or plastic film seal. When cooking, stewing food and fried vegetables, in order to preserve the original flavor of the food, prevent excessive evaporation of water, and accelerate the cooking speed, the vessel cover or plastic wrap should be used.

- Q: Can foil foil be put on and off?

- It can be assured that shading will not fall, light, pollution free and cheap. For high grade cigarettes, sweets and other food moistureproof and decorative packaging.

- Q: Why can copper foil and aluminum foil shield electromagnetic signals?

- Therefore, they usually back conductive adhesive, otherwise shielding effectiveness is very poor, under normal circumstances, with conductive adhesive copper foil / aluminum foil can reach more than 90dB, with flying conductive adhesive only about 40dB

- Q: Can foil work at 430 degrees high temperature?

- The melting point of aluminium is 660.4 degrees centigrade and the boiling point is 2467. The foil can resist high temperature, but it will be oxidized. A white powder, a covalent compound, having a melting point of 2050 DEG C and a boiling point of 3000 DEG C

Send your message to us

Aluminum Composite Foil High Strength Lightweight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords