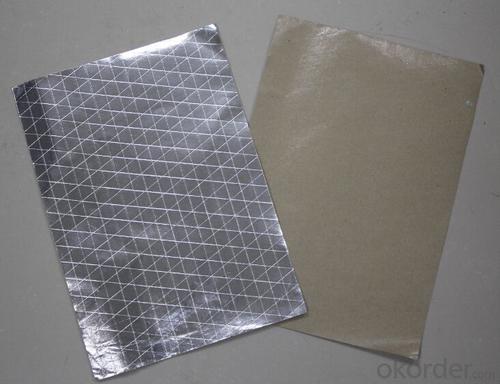

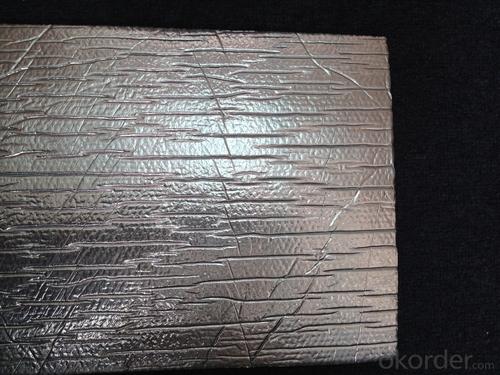

Fiberglass Facing Flexible Ducts Bubble Insulation Reflect

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: Describe the process of creating black fiberglass tissue, including the materials used and the steps involved.

- <p>The production process of black fiberglass tissue involves several key steps. First, raw materials such as glass fibers are combined with a black pigment or dye to color the fibers. These fibers are then melted and extruded into thin strands. The strands are gathered together and woven or laid into a sheet form to create the tissue. This sheet is then treated with a resin to bind the fibers together, resulting in a strong, black fiberglass tissue. The final product is often used in various industrial applications due to its strength and resistance to heat and chemicals.</p>

- Q: The question asks if it is safe to use black fiberglass tissues to clean car windows without causing scratches.

- <p>Yes, you can use black fiberglass tissues to clean your car windows without scratching them. These tissues are designed to be non-abrasive and gentle on surfaces, making them suitable for cleaning windows without causing damage. However, it's always a good idea to test a small, inconspicuous area first to ensure there is no adverse reaction. Additionally, ensure that the tissues are clean and free from any debris that could potentially scratch the glass.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other insulation materials, focusing on their properties and performance.

- <p>Black fiberglass tissue is a type of insulation material known for its durability and resistance to heat and moisture. Compared to other insulation materials, it offers a good balance of thermal resistance and affordability. It is lighter than many alternatives, such as mineral wool, and easier to handle, which can reduce installation time and costs. However, it may not provide the same level of sound absorption as materials like cellulose or mineral wool. Additionally, black fiberglass tissue can be less environmentally friendly due to its production process and may not be as effective in certain temperature extremes compared to rigid foam insulations. Overall, the choice between black fiberglass tissue and other insulation materials depends on specific project requirements, including budget, thermal performance needs, and environmental considerations.</p>

- Q: Explain the distinction between black and white fiberglass tissue, including their composition and potential applications.

- <p>Black and white fiberglass tissue are both made from glass fibers, but they differ in color and certain properties. Black fiberglass tissue typically contains carbon black, which provides UV protection and can improve the material's resistance to weathering. It is often used in applications where durability and resistance to sunlight are important, such as in the construction of boats and outdoor structures. White fiberglass tissue, on the other hand, does not contain carbon black and is generally used in applications where aesthetics are a priority, such as in the automotive and aerospace industries. It is also used in situations where the absence of color is beneficial, such as in the production of translucent composites.</p>

- Q: Are there any black fiberglass tissues specifically formulated for individuals with sensitive skin?

- <p>Yes, there are specific types of black fiberglass tissues designed for sensitive skin. These products are often made with gentler materials and are hypoallergenic to minimize irritation. They may also be fragrance-free and dermatologically tested to ensure they are suitable for those with sensitive skin. It's important to look for products that are labeled as suitable for sensitive skin when choosing black fiberglass tissues.</p>

- Q: What distinguishes black fiberglass tissue from gray in terms of properties and applications?

- <p>Black and gray fiberglass tissue differ primarily in their color and the raw materials used. Black fiberglass tissue is made from basalt fibers, which are known for their high tensile strength, heat resistance, and chemical stability. It is often used in high-temperature applications and for reinforcing materials. Gray fiberglass, on the other hand, is made from E-glass fibers and is characterized by its good electrical insulation properties and resistance to water and most chemicals. It is commonly used in electrical insulation, construction, and automotive applications. The choice between black and gray fiberglass tissue depends on the specific requirements of the application, such as temperature resistance, strength, and environmental factors.</p>

- Q: Does fiberglass facing help with soundproofing?

- Yes, fiberglass facing can help with soundproofing. Fiberglass is known for its excellent sound-absorbing capabilities, as it can effectively trap and dampen sound waves. When used as a facing material, fiberglass can enhance the soundproofing properties of a wall or ceiling by reducing noise transmission through it. The facing acts as a barrier that prevents sound from passing through, making it an effective solution for reducing noise pollution in various settings, such as homes, offices, studios, or even industrial environments. Additionally, fiberglass is lightweight, easy to install, and can be easily combined with other soundproofing materials for even better results.

- Q: What is the typical thickness of fiberglass facing?

- The typical thickness of fiberglass facing can vary depending on the specific application and requirements. In general, fiberglass facing is available in thicknesses ranging from 0.5 millimeters to 2 millimeters. Thinner fiberglass facing, around 0.5 to 1 millimeter, is commonly used for lightweight and flexible applications such as insulation and acoustic panels. Thicker fiberglass facing, around 1.5 to 2 millimeters, is often used for more heavy-duty applications where higher strength and durability are required, such as in construction and industrial settings. It is important to consider the specific needs and specifications of a project to determine the appropriate thickness of fiberglass facing to ensure optimal performance and functionality.

- Q: This question asks for the optimal methods to install black fiberglass tissues, which are commonly used for insulation or flooring purposes.

- <p>The best ways to install black fiberglass tissues for insulation or flooring involve the following steps: 1. Preparation: Ensure the area is clean and dry. 2. Measuring and Cutting: Measure the area and cut the fiberglass to fit precisely. 3. Laying the Fiberglass: Start from one corner and work your way across, ensuring the material lays flat without wrinkles. 4. Securing the Fiberglass: Use adhesive or mechanical fasteners to secure the fiberglass in place. 5. Overlapping: When necessary, overlap the sheets and secure the overlap to prevent gaps. 6. Finishing: Apply a vapor barrier or underlayment if required, and finish with the desired flooring material. Always follow the manufacturer's instructions for the specific product being used.</p>

- Q: Is it acceptable to use black fiberglass tissue as a packaging material?

- <p>Yes, black fiberglass tissue can be used for packaging materials. It is known for its strength, durability, and resistance to various environmental factors such as moisture and chemicals. However, it's important to ensure that the black fiberglass tissue meets any specific requirements or standards for packaging in your industry, such as food safety regulations or environmental considerations. Additionally, it's advisable to check if there are any legal restrictions or guidelines regarding the use of black fiberglass tissue in packaging to avoid any compliance issues.</p>

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Insulation Reflect

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords