Fiberglass Mat Tissue - E-Glass Chopped Strand Mat for Sanitary Ware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E-glass Chopped Strand Mat , Fiberglass Mat for Sanitary Ware

Introduction:

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moldings, such as, various sheets and panels, boat hulls, boat tubs, cooling towers, corrosion resistant, vehicles, etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

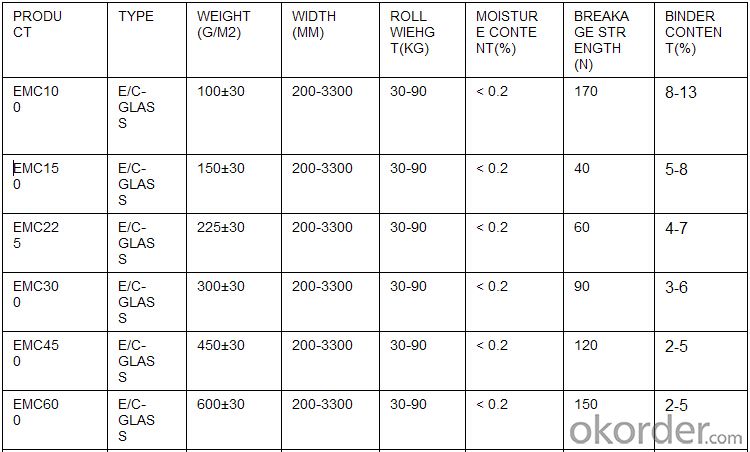

Technical Data:

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Is fiberglass mat tissue suitable for outdoor applications?

- Indeed, outdoor applications are well-suited for fiberglass mat tissue. This particular material is constructed from interwoven fiberglass strands, all effectively bound together by a specialized adhesive. Its exceptional resistance to water, weather, and UV radiation renders it particularly well-suited for deployment in outdoor settings. Its adaptability extends to a range of outdoor applications, including roofing, insulation, and construction projects. The waterproof and weatherproof qualities of fiberglass mat tissue guarantee its robustness and longevity even in the face of harsh environmental conditions. Moreover, its lightweight nature and user-friendly handling characteristics make it a highly versatile option for various outdoor endeavors.

- Q: Is fiberglass mat tissue fire-resistant?

- Yes, fiberglass mat tissue is fire-resistant.

- Q: Can fiberglass mat tissue be used for insulating radiant floors?

- Yes, fiberglass mat tissue can be used for insulating radiant floors. Fiberglass is a popular insulation material due to its excellent thermal properties and resistance to moisture. Fiberglass mat tissue, in particular, is designed to provide additional strength and durability to the insulation layer. When used in radiant floor systems, it helps to prevent heat loss and improve energy efficiency by creating a barrier between the heated floor and the cooler ground or subfloor. Additionally, fiberglass mat tissue is easy to install and can be cut to fit any shape or size, making it a versatile choice for insulating radiant floors.

- Q: Does fiberglass mat tissue require any special precautions during disposal?

- Yes, fiberglass mat tissue requires special precautions during disposal. It should be handled with care and disposed of in accordance with local regulations. Due to its composition, fiberglass mat tissue can release harmful fibers when disturbed, which can be a health hazard if inhaled. Therefore, it is important to wear protective clothing, gloves, and a mask when handling and disposing of fiberglass mat tissue. Additionally, it should be sealed in a plastic bag or container to prevent the release of fibers into the environment.

- Q: What is fiberglass mat tissue made of?

- Fiberglass mat tissue is made of fine strands of glass fibers that are woven together to form a thin, flexible fabric-like material. These glass fibers are typically made from molten glass that is drawn into very thin filaments and then coated with a binding agent to improve strength and durability. The woven structure of the fiberglass mat tissue helps to provide reinforcement and stability to various materials and products, making it an ideal choice for applications such as insulation, roofing, and composite materials.

- Q: Does fiberglass mat tissue provide good moisture control?

- Yes, fiberglass mat tissue does provide good moisture control. It is a highly effective material that helps to prevent moisture build-up and condensation by providing a barrier against water intrusion. Additionally, it helps to improve the overall insulation of the structure, further enhancing moisture control.

- Q: How is fiberglass mat tissue used in the production of chemical storage tanks?

- Fiberglass mat tissue serves as a reinforcement material in the manufacturing of chemical storage tanks. It is combined with resin to create a composite material that offers strength, durability, and protection against different chemicals. By layering the fiberglass mat tissue within the tank structure, its structural integrity is enhanced, and the risk of leakage is prevented. During the manufacturing process, resin, typically polyester or epoxy, is impregnated into the fiberglass mat tissue to establish a strong bond between the fibers and the matrix. This impregnated mat is then placed on a mold or mandrel and covered with additional layers of resin and mat, resulting in a laminate. The number of layers and thickness can vary based on the desired tank specifications and the chemicals it will store. The combination of fiberglass mat tissue and resin yields outstanding corrosion resistance, making it ideal for storing a wide range of chemicals. Fiberglass is inherently non-reactive and can endure exposure to harsh chemicals, acids, and alkalis without compromising the tank's structural integrity or degrading. Hence, fiberglass mat tissue is the preferred material for chemical storage tanks as it guarantees the safety of stored chemicals and minimizes the risk of leaks or contamination. Moreover, the utilization of fiberglass mat tissue enables the production of tanks with complex shapes and sizes. It can be easily molded and formed into various configurations, providing flexibility in design. This ensures that chemical storage tanks can be tailored to specific requirements and seamlessly integrated into diverse industrial applications. In conclusion, fiberglass mat tissue is indispensable in the manufacturing of chemical storage tanks. It reinforces the tank structure, offers chemical resistance, and facilitates the fabrication of tanks with diverse shapes and sizes. When combined with resin, it creates a durable and corrosion-resistant composite material, ensuring the secure storage of chemicals in a variety of industrial settings.

- Q: Can fiberglass mat tissue be used for insulating ductwork?

- Yes, fiberglass mat tissue can be used for insulating ductwork.

- Q: What are the different manufacturing processes for fiberglass mat tissue?

- Various manufacturing processes exist for fiberglass mat tissue, each aiming to create a distinct mat type with unique characteristics. One prevalent method is the wet-laid process. Initially, glass fibers are chopped into small fragments and dispersed in a water-based slurry. This slurry is then spread onto a moving screen or belt, allowing the water to drain off and generating a mat composed of randomly oriented fibers. Subsequently, the mat is dried and further treated to achieve the desired thickness and density. Another technique is the dry-laid process. Here, glass fibers are first transformed into a loose, fluffy mat using either air or mechanical means. Subsequently, the loose fibers are bound together using a binder material, such as resin or latex, which is sprayed onto the fibers. The binder solidifies, resulting in a cohesive mat with controlled thickness and density. A third process is the stitch-bonded process. In this procedure, individual glass fibers are mechanically stitched together using a series of needles. These needles pierce the fibers and interlock them, producing a bonded fabric. This approach enables the production of mats with high strength and dimensional stability. Lastly, the spunbond process involves extruding molten glass through fine spinnerets to create continuous filaments. These filaments are then accumulated onto a moving belt or screen, where they are bonded together using either heat or a binder. This method generates mats with uniform fiber distribution and high strength. In summary, the selection of a manufacturing process for fiberglass mat tissue depends on the desired properties of the final product, including strength, thickness, density, and dimensional stability. Each process possesses its own advantages and disadvantages, and manufacturers will choose the most suitable method based on their specific requirements.

- Q: Can fiberglass mat tissue be used for composite panel manufacturing?

- Yes, fiberglass mat tissue can be used for composite panel manufacturing. It is a common material choice for reinforcing composite panels due to its high strength, durability, and compatibility with various resin systems. The fiberglass mat tissue provides structural integrity and improved strength-to-weight ratio to the composite panel, making it suitable for a wide range of applications.

Send your message to us

Fiberglass Mat Tissue - E-Glass Chopped Strand Mat for Sanitary Ware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords