Borosilicate 3.3 Heat-resistant Glass Household Electrical Appliance Glass Panel Glass Tray BG33

- Loading Port:

- NANJING

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Borosilicate Float Glass3.3(BG33)

Our 3.3 borosilicate glass is extremely versatile too – you can use it for almost any purpose imaginable; such as microscope slides and petri dishes; kitchenware items like oven-proof baking dishes; art projects like stained-glass windows.

The possibilities are endless! Its lightweight yet strong construction allows for easy transport between workspaces so you can take your creations wherever they need to go.

And thanks to its crystal clear transparency, light passes through beautifully with no distortion whatsoever - making sure whatever design you come up with looks perfect every time!

Borosilicate Float Glass3.3 Introduction

This revolutionary glass is made of borosilicate, a special material that combines strength and durability with an extraordinarily high heat resistance.

Whether it's functional or decorative, this magnificent material will make any project look great while helping protect against extreme temperatures up to 500°C (932°F). And because of its excellent thermal shock properties, it won't cloud over time from frequent temperature fluctuations either!

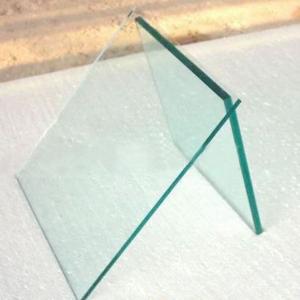

Borosilicate float glass 3.3 is a special glass material with low expansion rate, high emperature resistance, high strength, high hardness, high light transmittance and high chemical stability.

Because of its excellent performance, it is widely used in household appliances, environmental engineering, medical technology, safety protection and other fields, especially in the field of household appliances, borosilicate float glass 3.3 is widely used as the panel and inner tray of ovens and microwave ovens.

In addition, because the hardness of borosilicate float glass 3.3 is 8-10 times that of ordinary glass, it is also used as bulletproof glass by many customers.

Product Features

Great heat resistance performance

Stable chemical property

High light transmission

Various thicknesses for you to choose

Wide optical application

Application field

Borosilicate 3.3 serves as a material of true function and wide applications:

1). Household electrical appliance (panel for oven and fireplace, microwave tray etc.);

2). Environmental engineering and chemical engineering (lining layer of repellence, autoclave of chemical reaction and safety spectacles);

3). Lighting (spotlight and protective glass for jumbo power of floodlight);

4). Power regeneration by solar energy (solar cell base plate);

5). Fine instruments (optical filter);

6). Semi-conductor technology (LCD disc, display glass);

7). Medical technique and bio-engineering;

8). Safety protection (bullet proof glass)

Advantages

High borosilicate 3.3 glass is high-temperature resistant glass, heat-resistant glass and temperature difference resistant glass.

The linear expansion coefficient is 3.3 ± 0.1 × 10-6 / K, is a glass with sodium oxide (Na2O), boron oxide (b2o2) and silicon dioxide (SiO2) as the basic components.

The content of boron and silicon in the glass composition is relatively high, namely, boron: 12.5 ~ 13.5%, silicon: 78 ~ 80%.

The expansion coefficient will affect the stability of glass.

The expansion coefficient of borosilicate 3.3 heat-resistant glass is 0.4 times that of ordinary glass.

Therefore, at high temperature, borosilicate 3.3 heat-resistant glass still maintains excellent stability and will not crack or break.

The long-term working temperature of borosilicate 3.3 heat-resistant glass can reach 450 ℃, so it is often used as the microwave oven panel.

At high temperature, borosilicate 3.3 heat-resistant glass can not only work normally, but also maintain high permeability, which is convenient for users to observe the internal food state.

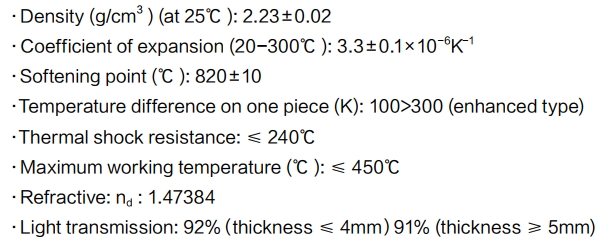

Technical Data:

Thickness Range: 2mm-20mm

Size: 1150*850 / 1700*1150 /1830*2440 /1950*2440 Max.3660*2440mm,

other specifications can be produced according to customer requirements.

Color: ultra-clear, transmittance 92%

Thermal properties

Optical data

Optical index of refraction:1.48

Mechanical properties

Density ρ (25°C) :2.23ɡ/cm3

Young's Modulus E (according to DIN 13316):64 kN/mm2

Poisson's Ratio μ (according to DIN 13316):0.2

Bending Strength σ (according to DIN 522922 T 1) :>25MPa

Packaging Photos of Borosilicate Glass 3.3

Package and transport

Minimum order quantity: 2 tons, capacity: 50 tons/day, packing method: wooden case.

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc

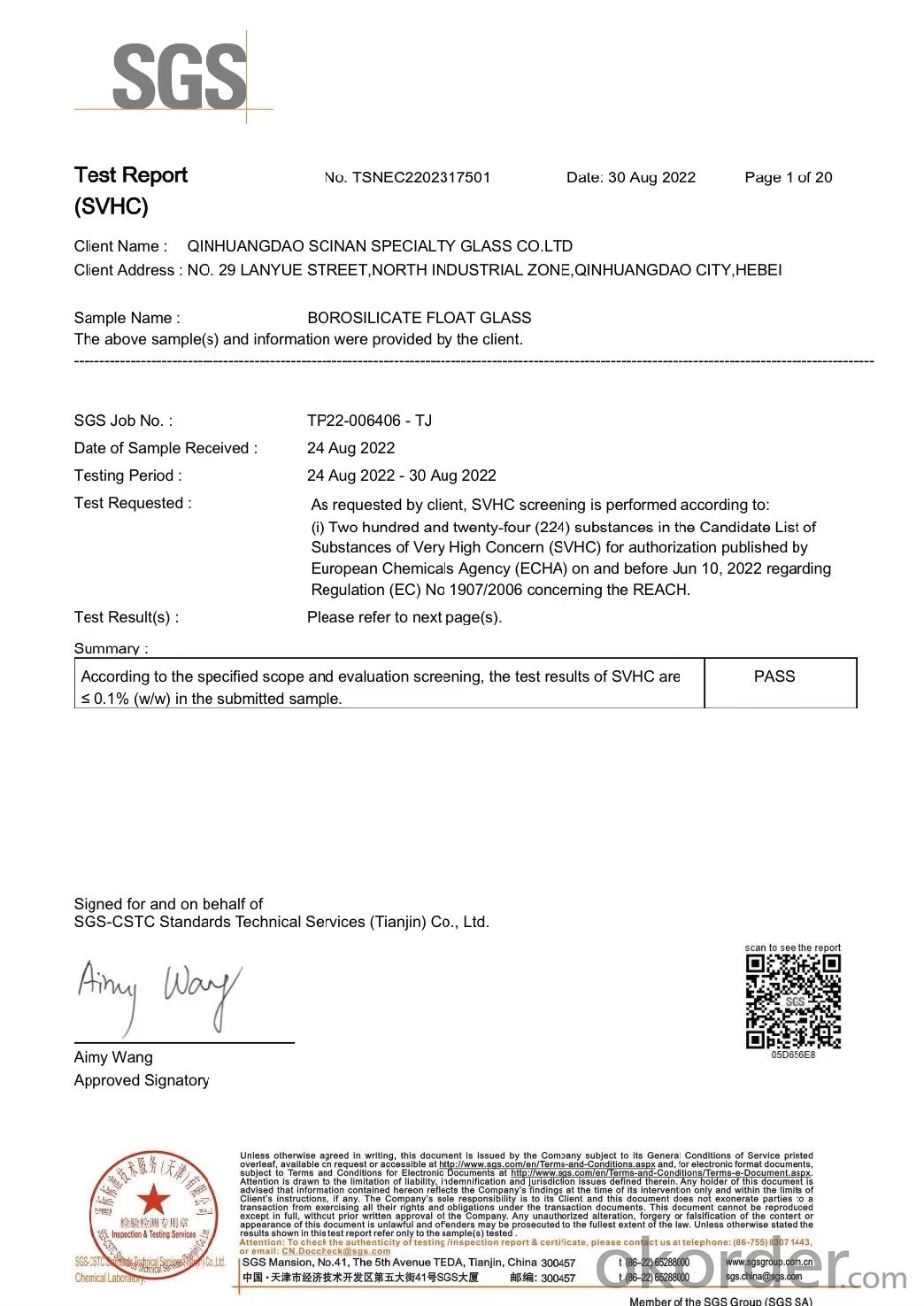

Our certification

At present, the company has passed the SGS certification the ISO9001 management system certification and so on.

The company has 21 national patents and obtained the certification of high-tech enterprises.

Our Advantage

It is the first high-tech enterprise in China to produce borosilicate flat glass products by full electrofusion technology.

At present, the domestic market share industry ranks first.

The core technology of the production line is self-developed, the key equipment is the most advanced industrial products, the company set borosilicate flat glass production, processing, sales and service as one, sales network has been spread throughout the country and many countries and regions of the world.

- Q: In Megamind when Titan takes off the building glass shatters, what does that mean scientifically ?

- It means that fantasy and reality are not one and the same thing. In a fantasy people can imagine what they want to. So for this fantasy you can picture a shock wave. Titan takes off by providing a very sudden very high force. Which radiates through the building shattering glass. Just like high explosive would. But this is only a background to a plausible fiction.

- Q: Alright, so I want to build an under seat sub woofer enclosure for my smaller sports coupe. There's not much room at all under the seats, so I was thinking about going with a Pioneer 8" shallow mount sub, but the box is causing me a bit of a headache. I haven't had a chance to take a measuring tape to it, and doing so would be difficult.My idea is to get a can of the spray foam stuff used to seal homes, to inflate a garbage bag under the seat. After letting it sit and dry for a while, I'll remove the seat, pull the bag out with the exact dimensions of my seat and then play from there. I'll take the bag off of the foam and probably sand it down from there to fit my needs. I'll then use fiber glass to build up the box from the foam mold.Any thoughts on better ways to do this?PS: The car is a 2000 Mercury Cougar incase anyone has actual dimensions.

- you can take the seat out and then use a think foil paper and line under the seat then put a thin layer of fiber glass then let it dry and go from there also. * remember when your using the fiberglass your also gonna want to put a layer of bondo to strengthen the box but you do have a good idea also what ever works.

- Q: My living room west sun, want to paste a window in the insulation film. Will the glass insulation film is doing? Are you going to work? Will the house darken?

- OKorder above the US base film is good, to see the evaluation, I believe the masses

- Q: How to build a glass water wall?

- There are so many different types. It would depend on what type of fall you are looking for. Please add details.

- Q: Manganese dioxide itself is black, why as a colorant added to the glass to show purple it

- Ordinary glass is made of quartz sand, soda ash and limestone, which is a mixture of silicate that is not fixed. The first glass produced by people is some of the poor transparency, with some small color The color of the glass is not used to make the ornaments, the requirements are not high, people just accidentally produced the color of the glass is not used to do the decoration, Out of the color of the glass, but today we require the color glass has a very high scientific requirements, which only opened the glass after the secret, can be made out.

- Q: I need an answer by thursday morning 7 am

- Depends on the size. The glass pyramid over the Louvre cost millions. On the other hand, you could build one the size of your head for about five bucks. A glass pyramid the size of those in Egypt would cost tens of millions. What did you have in mind?

- Q: Which brand of glass ink is good?

- If not high temperature sintering ink, then OKorder Fuhai company for the good oil,

- Q: What are the types of architectural glass materials?

- 【classification】: 1. Window glass: Window with flat glass, also known as plain glass or glass, referred to as glass, is not polished flat glass. Mainly used for building doors and windows, walls, outdoor decoration, play light, heat insulation, sound insulation, wind and protection role, can also be used for shop counters, windows and some means of transport (cars, Doors and windows. Window with the thickness of flat glass generally 2,3,4,5,6 mm five, of which 2 ~ 3mm thick, commonly used in civil construction, 4 ~ 6mm thick, mainly for industrial and high-rise buildings. 2. Polished glass: polished glass, said mirror glass or white glass, polished polished flat glass, single-sided polished and double-sided polished two, polished glass is to eliminate the glass containing Glass and other defects. Polished glass surface smooth and shiny, from any direction perspective or reflection of the scene are not deformed, the thickness is generally 5 ~ 6mm, size can be produced according to need. Commonly used to install large high-level doors and windows, windows or mirror.

- Q: Domestic architectural glass insulation film which brand is good

- Do you say domestic brands? I do not recommend posted domestic brands, it is best to choose foreign brands, such as iUQE, ten years warranty, will not release harmful substances.

- Q: Not man-made destruction of tempered glass why suddenly broken

- Tempered glass has bleed characteristics This is because the glass raw materials containing nickel sulfide crystals, is the world's existing manufacturing technology can not be completely avoided, only through the purity of raw materials and processing technology to control the risk of a little lower blew. On the concept of self-blasting rate, our country only on the external walls of the engineering glass has a national standard, I do not know whether the foreign industry for the use of tempered glass also has detailed provisions. One ton of glass raw materials, there are at least 3-4 nickel sulfide crystals, this one ton of glass made of several square meters of the size of the glass, which will have 3-4 tablets blew, which is blew the image depicting.

Send your message to us

Borosilicate 3.3 Heat-resistant Glass Household Electrical Appliance Glass Panel Glass Tray BG33

- Loading Port:

- NANJING

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Qinhuangdao Scinan Special Glass Co., Ltd.

Qinhuangdao Scinan Special Glass Co., Ltd.