Heat Resistant Borosilicate Glass 3.3 used for Projector lens

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description:

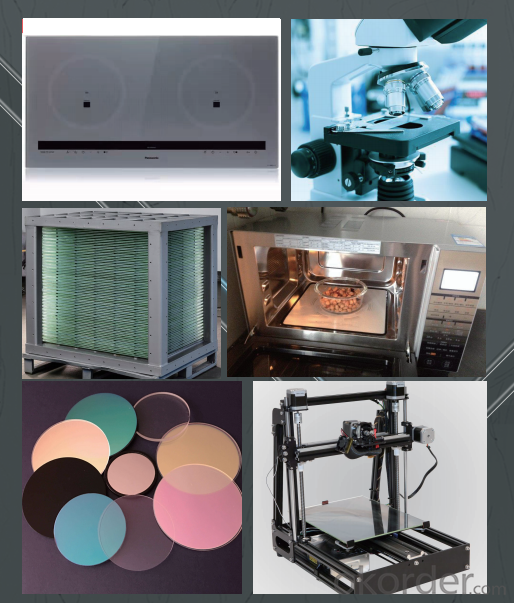

Borosilicate 3.3 serves as a material of truly functional and wide applications:

1). Household electrical appliance (panel for oven and fireplace, microwave tray etc.);

2). Environmental engineering and chemical engineering (Lining layer of repellence, autoclave of chemical reaction and safety

spectacles);

3). Lighting (spotlight and protective glass for jumbo power of floodlight);

4). Power regeneration by solar energy (solar cell base plate);

5). Fine instruments (optical filter);

6). Semi-conductor technology (LCD disc, display glass);

7). Iatrology and bio-engineering;

8). Safety protection (bullet proof glass)

Name | Borosilicate Glass 3.3 |

shape | can make as customer’s request |

Glass Type | Heat resistant Glass |

place of origin | China |

Structure | solid |

Packing | Meet customer's personal requirement |

Color | clear |

Size | 600*800 2200*1650 2440*1830 3300*2140 3660*2140 3660*2440 |

Packing | Wooden box |

Application | Projector lens |

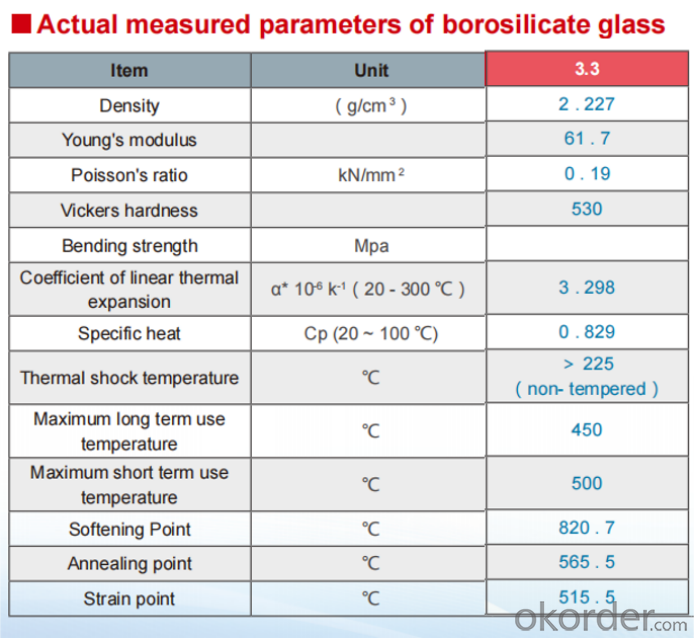

2. Actual measured parameters of Borosilicate Glass:

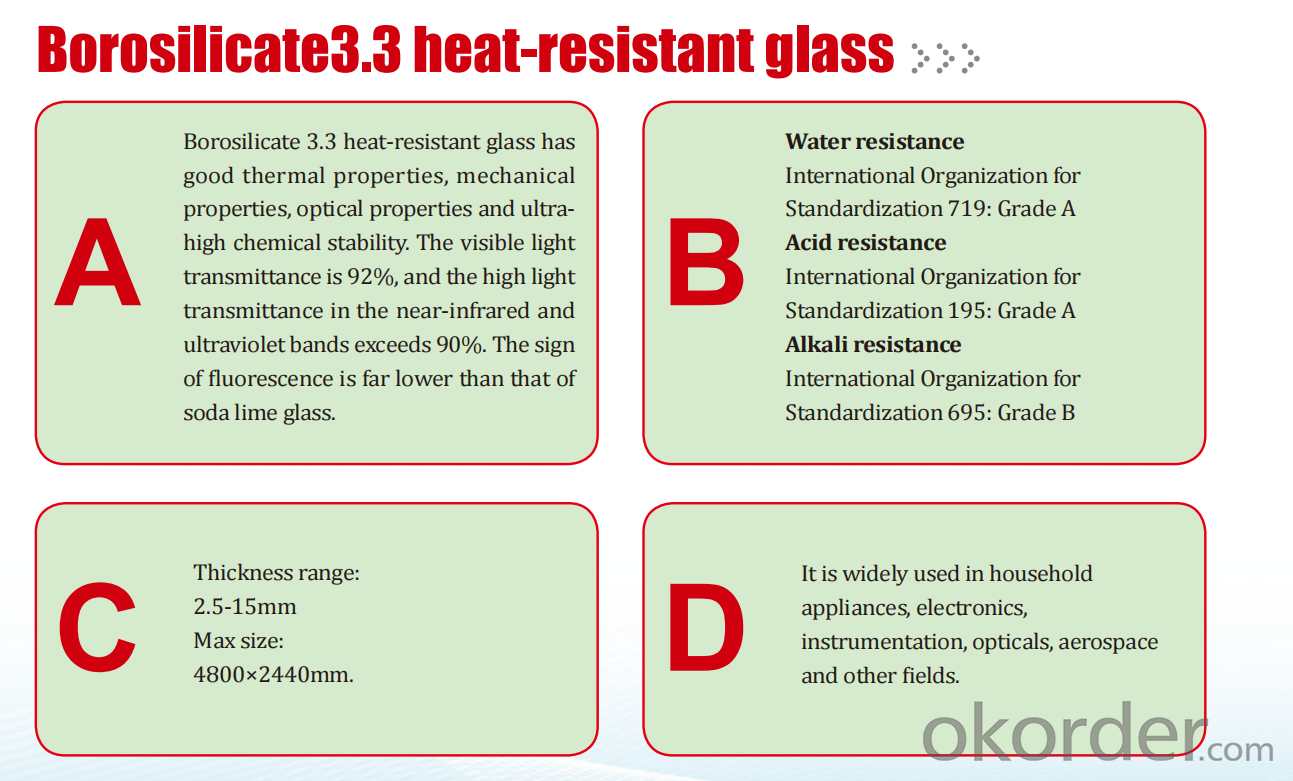

3. Main features:

1. Great heat resistance performance, stable chemical properties

high strength;

2. High light transmittance;

2. High light transmittance;

3. Super acid and alkali resistant;

4. Wide optical applications.

4. Advantage:

Because of the ionic bond, it has good thermal properties, mechanical properties and chemical stability, such as low expansion coefficient, high softening temperature, high strength, low density, and not easy to mold and fog.

CNBM’s largest Size: 4800X2440mm

5. Application Area:

Can be used in fireproof curtain walls, partition walls, platforms, day lighting roofs, smoke-proof vertical walls, railings, doors and windows, elevator shafts, rail transit platform screen doors, rail locomotive doors and windows and other fields. Equipped with water spray, it can be used to replace Class A insulation type fireproof glass system, which can be widely used in building atrium, pedestrian street fireproof glass and building fireproof partition.

More Applications:

l The scope of application:

a) Indoor heating/The windows panel heaters

b) Cover glass heating radiator

c) Reflecting cupand High performance pan light lamp cover

d) Infrared dryer cover

e) Projector protection cover

f) UV shield

g) Barbecue machine panel

6. Process:

7. Packing and Shipping:

All the glass will pack in strong export plywood crates, and load in container strong firmly, to make sure safety delivery.

8. Test Report:

9. Company Brief:

10. FAQ:

Q1:What’s your MOQ?

A: Generally, there is 2 tons for MOQ , CNBM will give you more discount if quantity more.

Q2:Can you send me some samples to check your quality?

A:Sure, CNBM Glass could send the free samples (except special deep processing glass) for you any time. we will refund the courier charge for you once we start business.

Q3:What's the fast production time you can do?

A: It depends on the quantity of building glass you need. Normally it takes 15-45 days after drawing confirmed.

Q4:How can you make sure the glass won't broken during transportation?

A: For all the glass from our factory,we will pack them into strong export plywood crates and load the crates into container with metal belt as stable as possible. If unfortunately by accident, the glass broken, we will have insurance to cover the risk, because for all the glass from our company, we will purchase the insurance to cover all the risk for customers freely.

Q5:How can i get the best price?

In order to offer our best price for you, please send all the details as below for us:

a. what size and thickness of clear float glass/tempered glass/laminated glass are you looking for?

b. How about the approximate quantity?

c. Do you have any special requirement like drill holes, cut notches,cutouts, acid etched, silkscreen?

d. When do you need those glass?

- Q: The use of quartz sand

- Derived from various magmatic rocks, sedimentary rocks and metamorphic rocks, less heavy minerals, associated minerals are feldspar, mica and clay minerals. There are two kinds of sedimentary rock genesis and metamorphic origin, the former is not obvious between clastic particles and cement, and the latter refers to quartz rocks with deep metamorphic and pure quality. The quartz veins are formed by hydrothermal action, almost all of them are composed of quartz, and they are compact and massive structures.The mineral content of quartz sand varies greatly, mainly quartz, followed by feldspar, mica, cuttings, heavy minerals and clay minerals.

- Q: How is the glass made?

- The shape of each vessel is irregular. It is shining like a holy lotus under the light. It was introduced that the vessel was blown through a wooden mold. In the 30s of the last century, Artaud also successfully designed many glassware, this free form of utensils is still in production, has become one of Artaud's masterpiece.

- Q: Is acrylic organic glass?Which is more expensive, acrylic or plexiglass?

- Organic glass is an important heat, a development of earlier plastic, with transparency, chemical stability and good weathering resistance, easy to dye, easy processing, beautiful appearance, is widely used in the construction industry. The plexiglass product usually can be divided into casting plate, plastic extrusion board and the mold.Acrylic is much more expensive than plexiglass

- Q: Can the toughened glass be cracked by the sun?

- high strengthThe toughened glass of the same thickness has 3~5 times the impact strength of ordinary glass, and the bending strength is 3~5 times of that of ordinary glass.

- Q: What is glass fiber reinforced nylon?

- With excellent wear resistance, heat resistance and electrical properties, high mechanical strength, self extinguishing, good dimensional stability, widely used in automotive industry products, textile products, pump impeller and first class precision engineering componentsPA6 enhancement series:With good wear resistance, heat resistance, oil resistance and chemical resistance, but also greatly reduce the water absorption and shrinkage of raw materials, with excellent dimensional stability and excellent mechanical strength

- Q: What are the raw materials for making glass?

- The material used to make glass is mainly sandstone, limestone, and feldspar. The sandstone is the main component of the glass material, and its chemical composition is silica.

- Q: Glass raw materials, in addition to quartz sand, what else can be the main raw materials?

- Soda ash, limestone, quartz, the ratio is: 1:1:6

- Q: What kind of material is the glass made of? Is the price relative to the quality?

- The main raw material of silicon dioxide, the price is related to the quality

- Q: The practice of acid corrosion in tank

- The performance of loading and canning is excellent. The heavy duty coating can keep good storage stability, and the rheological and shearing properties of the coating are constant, and the temperature change is less affected. No delamination after opening, no precipitation, easy to disperse and stir.

- Q: Are there any materials that need to be tested in curtain work?

- Main profiles (including aluminum and steel profiles), screws, bolts, drawing test, four test, hardware fittings, etc.

Send your message to us

Heat Resistant Borosilicate Glass 3.3 used for Projector lens

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches