Borosilicate 3.3 Heat-resistant Glass(Optical lens)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product introduction:

Borosilicate glass 3.3 is a type of glass that has become increasingly popular in recent years, due to its excellent thermal and chemical resistance properties. It is composed mainly of silica, boric oxide, aluminum oxide, sodium oxide, and other oxides. This specific combination makes it ideal for use in optical lenses as well as various types of laboratory equipment. Borosilicate 3.3 glass can be used as optical lens for cameras and other equipment.At the same time, its wear resistance is also very prominent.

Borosilicate Glass Optical Lenses are used for a variety of applications such as microscopy and telescopes. The combination of the borosilicate glass material with the precision-made optics allows for superior performance when compared to standard plastic or acrylic lenses. Additionally, Borosilicate Glass Optical Lenses provide increased clarity and color fidelity which helps reduce eye fatigue during extended viewing sessions.

The composition of Borosilicate Glass 3.3 makes it particularly suitable for high temperature use without compromising on strength or durability; this property can be beneficial when creating optical lenses which require higher temperatures during production processes than what traditional glasses can handle without cracking or melting under pressure.

Technical Data

Thickness Range:2mm-20mm

Color: ultra-clear, transmittance 92%

Thermal properties

Coefficient of Linear Thermal Expansion (C.T.E) α (20°C~300°C): 3.3×10-6 K-1

Specific heat capacity cƤ (20-100°C) :0.83kJ/(kg·K)

Thermal conductivity λ (90°C):1.2 W/(M·K)

Heat shock temperature:240°C

Annealing Point:560°C

Strain Point: 510°C

Optical data

Optical index of refraction:1.48

Mechanical properties

Density ρ (25°C) :2.23ɡ/cm3

Young's Modulus E (according to DIN 13316):64 kN/mm2

Poisson's Ratio μ (according to DIN 13316):0.2

Advantages

High borosilicate 3.3 glass is high-temperature resistant glass, heat-resistant glass and temperature difference resistant glass. The linear expansion coefficient is 3.3 ± 0.1 × 10-6 / K, is a glass with sodium oxide (Na2O), boron oxide (b2o2) and silicon dioxide (SiO2) as the basic components. The content of boron and silicon in the glass composition is relatively high, namely, boron: 12.5 ~ 13.5%, silicon: 78 ~ 80%.

The expansion coefficient will affect the stability of glass. The expansion coefficient of borosilicate 3.3 heat-resistant glass is 0.4 times that of ordinary glass. Therefore, at high temperature, borosilicate 3.3 heat-resistant glass still maintains excellent stability and will not crack or break.

Note:

Borosilicate Glass 3:3 offers many advantages regarding its usage when making complex optical lenses such as microscopes or telescope components; not only does it have excellent properties against heat distortion but also provides exceptional clarity & colour fidelity necessary when viewing objects at either microscopic level or great distances away respectively - offering users much better visual experiences than many other materials out there today regardless if they’re using them recreationally through hobbyist activities like astronomy/birdwatching etc., professionally through medical research etc.

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc

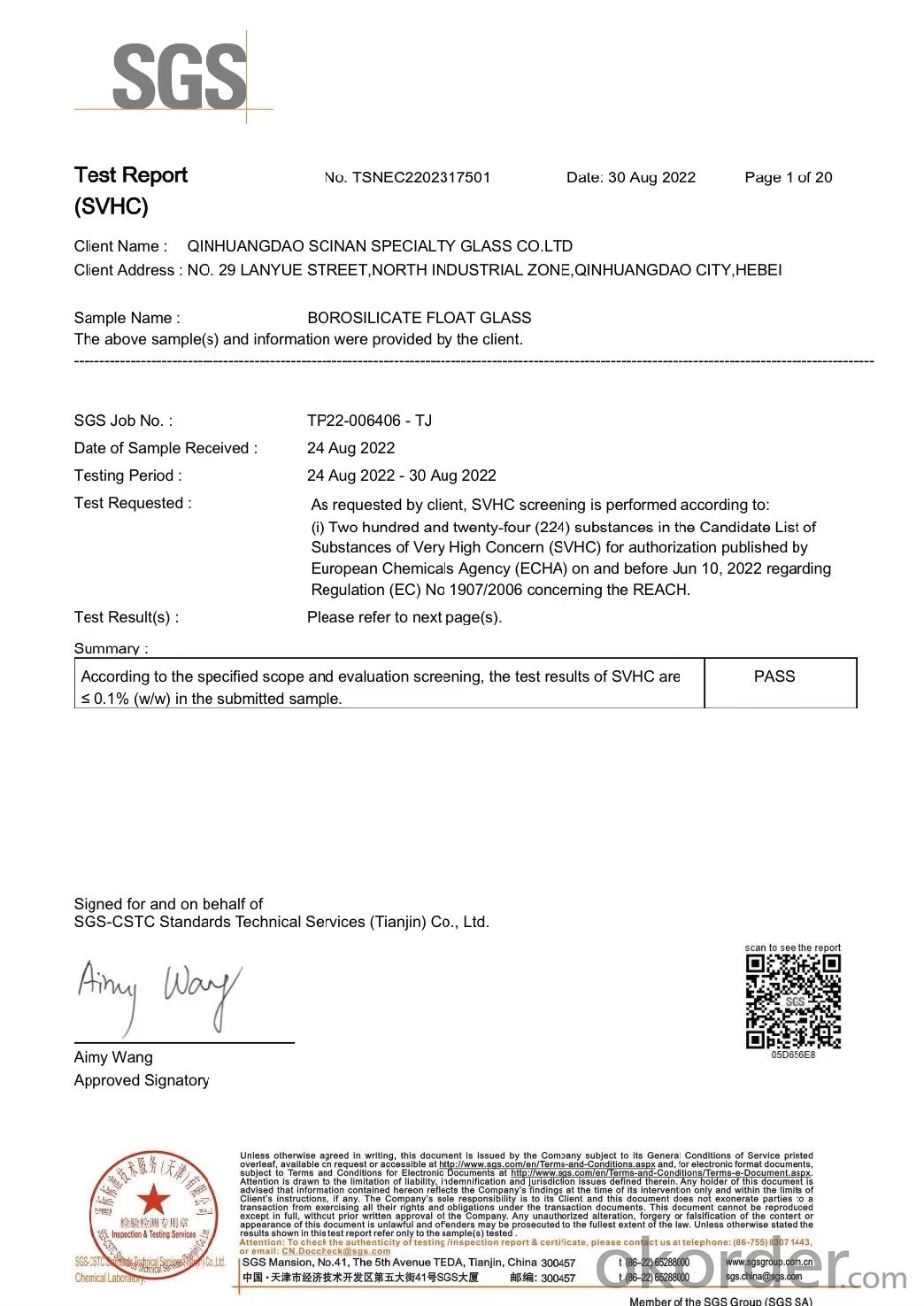

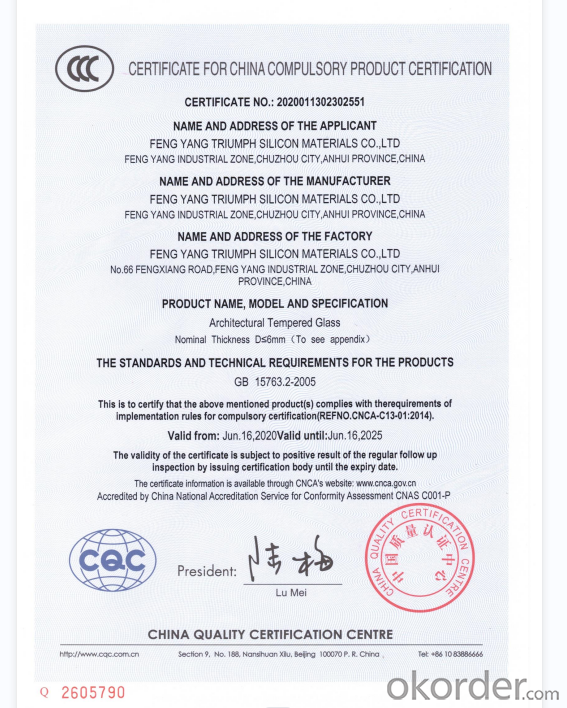

Our company has passed the SGS certification 、SISO9001:2015 certification, and we have also passed the Certificate China National Compulsory Product Certification.Our company has obtained more than 20 national patents,and fireproof glass test report.

Company Introduction

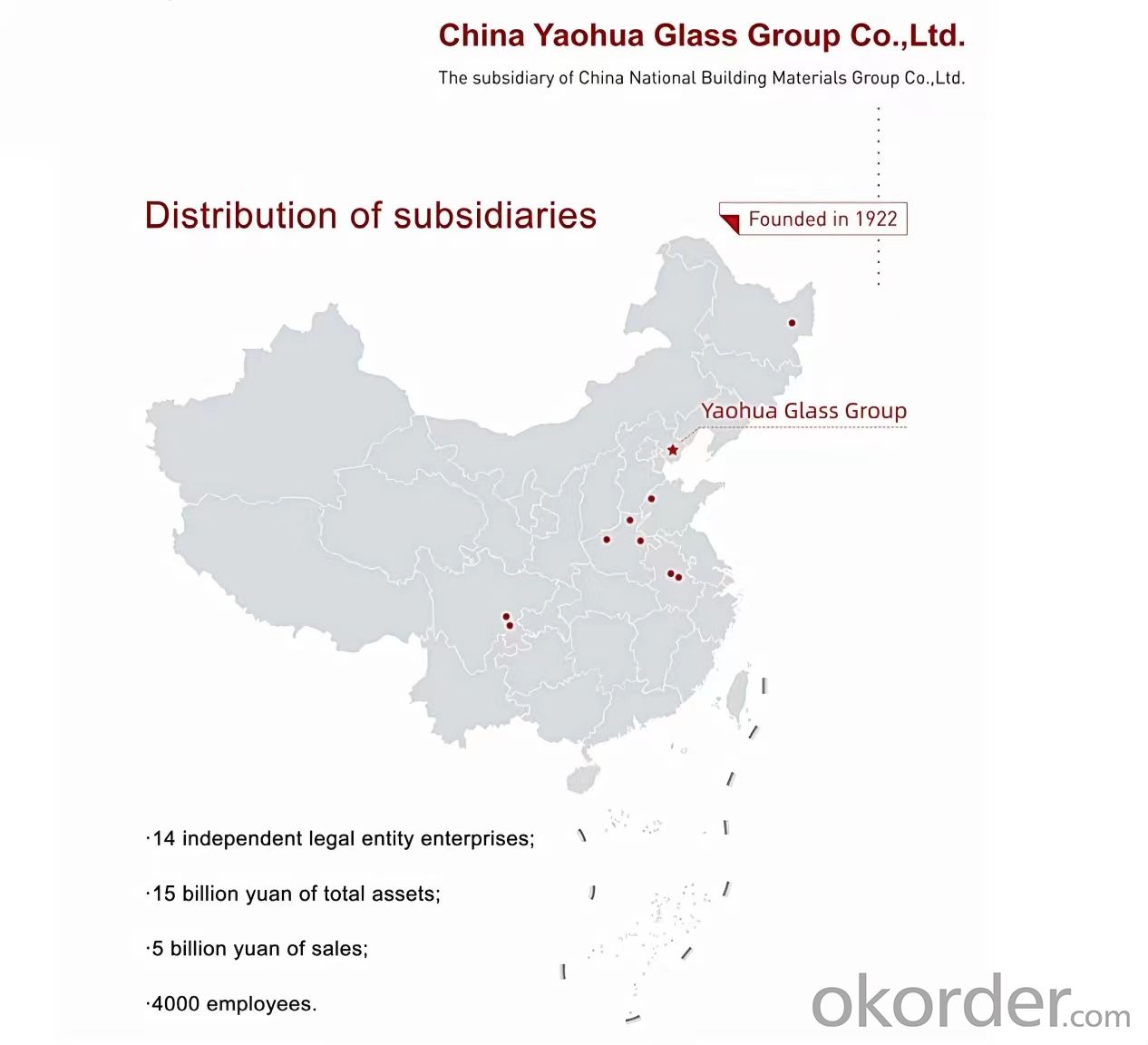

China Yaohua Glass Group Co., Ltd.

founded in 1922, china yaohua glass group co., ltd. (hereinafter referred to as "yaohua group”) is a second-tier subsidiary of triumph science&technology co. ,ltd. it is the first manufacturer in asia to continuously produce flat glass by machine,and is known as “the cradle of chinese glass industry”.

yaohua group, as the core platform of triumph science & technology group for high-quality float and special glass, now has 14independent legal entity enterprises, with assets of over 10-billion-yuan, annual revenue of more than 5 billion yuan and total annual profit of more than 1 billion yuan. the group covers 10 prefecture-level cities in six provinces including heilongjiang, hebei, shandong., henan, anhui and sichuan, with 4000 employees.

it has three sectors float glass, special glass and deep-processing glass. the special glass unties composed of engyang triumph silicon materials co., ltd. 、 qinhuangdao scinan specialty glass co., ltd.、triumph bnegbu glass co., ltd. and cnbm(puyang) photoelectric materials co., ltd.

Qinhuangdao Scinan Specialty Glass Co., Ltd.

Company Introduction

Founded in 2009 with 65.47 million registered capital and 162 employees, Qinhuangdao Scinan Specialty Glass Co.,Ltd. formerly known as “Qinhuangdao Yaohua Special Glass Co., Ltd.”. The company’s leading products borosilicate flat glass, the annual production capacity of 16425 tons, the products to 3.3 borosilicate flat glass based.

Qinhuangdao Scinan Specialty Glass Co.,Ltd. has researched and developed borosilicate glass products for about 20 years, and has a technical team with excellent professional knowledge and rich experience.

Located in Funing District, Qinhuangdao, the new park is expected to have an annual production capacity of 17,520 tons. It plans to produce 2.6 borosilicate and 3.3 borosilicate glass for household appliances, and 4.0 borosilicate fire-resistant glass. The project is expected to be completed by the end of 23 years.

Our service

We provide high-quality services throughout the process:

Before sales, we provide professional product introduction

In sales, we provide high-quality products

After sales, we have a perfect after-sales system

Our advantage

It is the first high-tech enterprise in China to produce borosilicate flat glass products by full electrofusion technology. At present, the domestic market share industry ranks first. The core technology of the production line is self-developed, the key equipment is the most advanced industrial products, the company set borosilicate flat glass production, processing, sales and service as one, sales network has been spread throughout the country and many countries and regions of the world.

- Q: Theoretically, if glass dropped and the stress incurred was just less than that required to shatter it, would the next drop, no matter how small, break the glass? If not can it continue to take infinitely more stress damage as long as they each individually do not surpass its stress limit, even though their sum does?Note: I am asking this with the real life application of the glass backs of iPhones in mind

- You should investigate what the amount of energy is required to cause a defect either in manufacturing or physical damage to initiate and propagate a crack. The defect may be improper heat treatment, a foreign inclusion, a void in the glass matrix, a nick or scratch in the casting process or in handling in the production line, for example. Each cycle of dropping could potentially have enough energy to further propagate the crack until full fracture is achieved, You may want to investigate fracture mechanics. .

- Q: Introduction to Building Membrane Materials

- Building film is the use of PET (polyethylene) substrate, leading the use of multi-layer metal sputtering technology and vacuum technology and ion technology and thin film physics, fine chemical technology, it has a very high heat insulation efficiency, high tension, Strong acid and alkali resistance. And the color is rich natural, the test results show that: can block 81% of the solar energy; in the outdoor temperature of 38 ℃ ~ 39 ℃, lower than the average glass temperature of 3.5 ℃, saving more than 30% of the air conditioning power consumption, Energy - saving safety materials.

- Q: New glass features

- plate glass Flat glass is not processed by other flat glass products, also known as white glass or clean glass. According to the production method is different, can be divided into ordinary flat glass and float glass. Flat glass is the largest in the building glass, the most used one, mainly for doors and windows, from lighting, enclosure, insulation, sound insulation and other effects, but also further processed into other technical glass of the original film. Flat glass according to its use can be divided into window glass and decorative glass. According to the national standard "ordinary flat glass" and "float glass" provisions, the glass according to its thickness can be divided into the following specifications: In accordance with national standards, flat glass according to its appearance quality classification grading, ordinary flat glass is divided into superior products, first-class goods and second-class three grades. Float glass is divided into three grades: superior grade, first grade and qualified product. Flat glass use has two aspects: 3 ~ 5mm flat glass is generally used for doors and windows of the lighting, 8 ~ 12mm flat glass can be used to cut off. Another important use is as the original film of tempered, interlayer, coated, hollow and other glass.

- Q: China's well-known foreign glass factory which several

- Glass is a big industry, there are many subdivisions, such as flat glass, architectural glass, medical glass, ultra-white glass, etc., China Southern Glass Group Co., Ltd The Group is headquartered in Shekou, OKorder, with subsidiaries in Australia, the Middle East and Hong Kong. The Group's top ten production and raw materials bases are located in OKorder, Dongguan, Guangzhou, Chengdu, Tianjin, Langfang, Wujiang, Yichang, Hainan Wenchang, Sichuan Jiangyou and other places

- Q: I am about to build an all-glass aquarium, the glass edge-joined with silicon. I have seen it done a number of times and am confident I am able to do it. The finished tank size will be 150cm long, 60cm tall and 50cm deep. I intend to brace the front and back as well as the two sides and also put two cross braces running front to back at the top of the tank at 50cm and 100cm intervals. Does anybody know how I should calculate the glass thickness or, alternatively, does anyone out there have a tank of a similar size they could tell me what the dimensions of theirs is.Thanks

- This Site Might Help You. RE: Home built glass aquarium - how thick should the glass be? I am about to build an all-glass aquarium, the glass edge-joined with silicon. I have seen it done a number of times and am confident I am able to do it. The finished tank size will be 150cm long, 60cm tall and 50cm deep. I intend to brace the front and back as well as the two sides and also put...

- Q: Head of the town of glass steel factory in what way

- You want to see what you do glass car glass glass glass art glass building glass equipment is not the same as I said the next building glass equipment, cutting machine two, milling machine (unilateral, bilateral grinding), shaped machine, Drilling machine, etc. Third, the steel furnace four, plastic pre-pressure line, autoclave Fifth, the hollow production line These are the construction of glass more complete production machinery

- Q: LOW-E Insulating Glass Price (6 + 6A + 6)?

- Upstairs price a bit scary of the CSG hollow is indeed their own production of Yao leather are foreign companies of the process is the same, but their institutions are huge management costs so expensive.

- Q: What parts of the building curtain wall project?

- Building curtain wall is the building does not bear the external wall of the Wai, usually by the panel (glass, metal plate, slate, ceramic plate, etc.) and the back of the support structure (aluminum beam column, steel structure, glass ribs, etc.).

- Q: If there is no air conditioning at home, how to make the room cooler,

- Reasonable opening and closing doors and windows. Many people think that the summer doors and windows to open only cool, it is not true. During the day and outside the high temperature, doors and windows open, the sun and heat radiation accompanied by bursts of hot air to the indoor hit, will become indoor and outdoor heat. If you open the doors and windows in the morning and evening when the ventilation, so that air circulation, and especially during the day and afternoon will be closed doors and windows to isolate the hot air outside the invasion, and pull the light curtains, blocking the sun, reflecting the heat radiation, Become cooler. The actual observation, the author living in Chengdu, although the afternoon outdoor air temperature of more than 30 degrees, using the above method can still be maintained at 28 ℃ or so.

- Q: Building glass specification is that set?

- (JGJ 113-2009), "Construction Safety Glass Management Regulations" (Development and Reform Commission [2003] No. 2116), "Specification for Design, Construction and Acceptance of Aluminum Alloy Doors and Windows", "Regulations for the Application of Building Glass" (JGJ 113-2009) (DBJ15-30-2002).

Send your message to us

Borosilicate 3.3 Heat-resistant Glass(Optical lens)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Qinhuangdao Scinan Special Glass Co., Ltd.

Qinhuangdao Scinan Special Glass Co., Ltd.