Manufacturers produce borosilicate 3.3 heat-resistant glass(Microwave oven glass panel,glass tray)

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

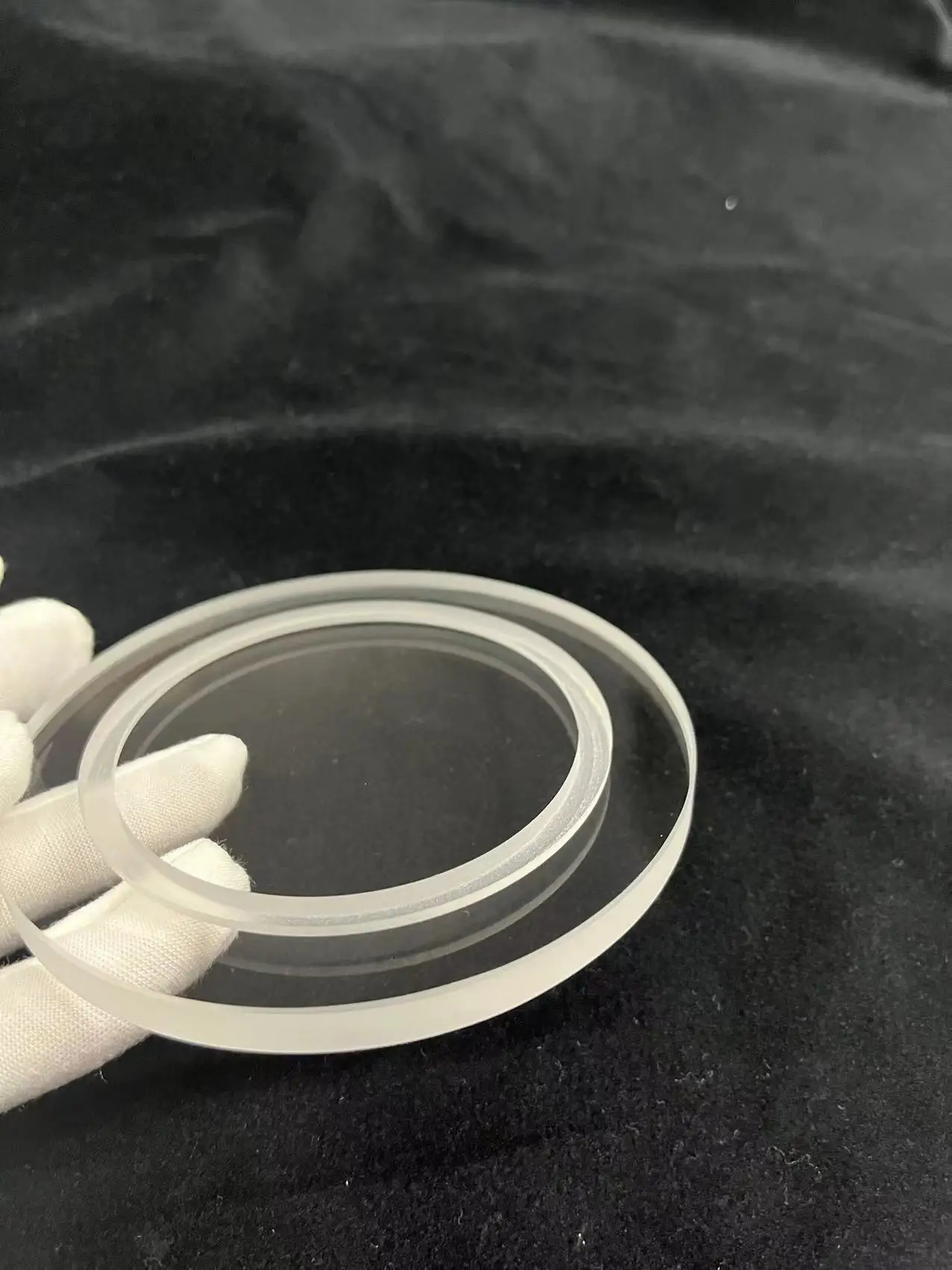

Manufacturers produce borosilicate 3.3 heat-resistant glass(Microwave oven glass panel,glass tray)

Product Introduction

This revolutionary glass is made of borosilicate, a special material that combines strength and durability with an extraordinarily high heat resistance.

Whether it's functional or decorative, this magnificent material will make any project look great while helping protect against extreme temperatures up to 500°C (932°F). And because of its excellent thermal shock properties, it won't cloud over time from frequent temperature fluctuations either!

Borosilicate float glass 3.3 is a special glass material with low expansion rate, high emperature resistance, high strength, high hardness, high light transmittance and high chemical stability.

Because of its excellent performance, it is widely used in household appliances, environmental engineering, medical technology, safety protection and other fields, especially in the field of household appliances, borosilicate float glass 3.3 is widely used as the panel and inner tray of ovens and microwave ovens. In addition, because the hardness of borosilicate float glass 3.3 is 8-10 times that of ordinary glass, it is also used as bulletproof glass by many customers.

Application field

Borosilicate 3.3 serves as a material of true function and wide applications:

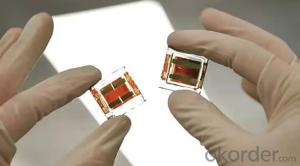

1). Household electrical appliance (panel for oven and fireplace, microwave tray etc.);

2). Environmental engineering and chemical engineering (lining layer of repellence, autoclave of chemical reaction and safety spectacles);

3). Lighting (spotlight and protective glass for jumbo power of floodlight);

4). Power regeneration by solar energy (solar cell base plate);

5). Fine instruments (optical filter);

6). Semi-conductor technology (LCD disc, display glass);

7). Medical technique and bio-engineering;

8). Safety protection (bullet proof glass)

Advantages

High borosilicate 3.3 glass is high-temperature resistant glass, heat-resistant glass and temperature difference resistant glass. The linear expansion coefficient is 3.3 ± 0.1 × 10-6 / K, is a glass with sodium oxide (Na2O), boron oxide (b2o2) and silicon dioxide (SiO2) as the basic components. The content of boron and silicon in the glass composition is relatively high, namely, boron: 12.5 ~ 13.5%, silicon: 78 ~ 80%.

The expansion coefficient will affect the stability of glass. The expansion coefficient of borosilicate 3.3 heat-resistant glass is 0.4 times that of ordinary glass. Therefore, at high temperature, borosilicate 3.3 heat-resistant glass still maintains excellent stability and will not crack or break.

The long-term working temperature of borosilicate 3.3 heat-resistant glass can reach 450 ℃, so it is often used as the microwave oven panel. At high temperature, borosilicate 3.3 heat-resistant glass can not only work normally, but also maintain high permeability, which is convenient for users to observe the internal food state.

Our 3.3 borosilicate glass is extremely versatile too – you can use it for almost any purpose imaginable; such as microscope slides and petri dishes; kitchenware items like oven-proof baking dishes; art projects like stained-glass windows.the possibilities are endless! Its lightweight yet strong construction allows for easy transport between workspaces so you can take your creations wherever they need to go. And thanks to its crystal clear transparency, light passes through beautifully with no distortion whatsoever - making sure whatever design you come up with looks perfect every time!

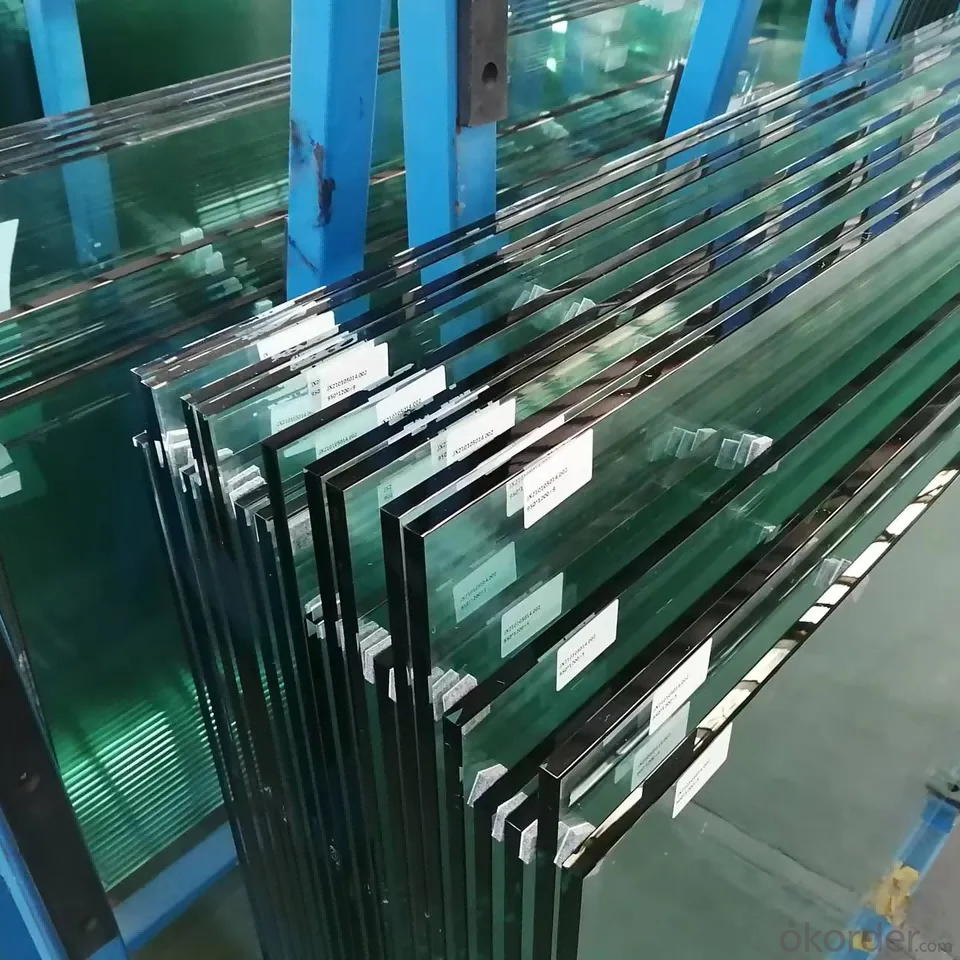

Packaging Photos of Borosilicate Glass 3.3

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: What is the fire cut off?

- Partition refers to the facade that is dedicated as a compartmentalized space. Fire cut off is the fireproof material to do!

- Q: Brother and sister! I would like to get a fire on the material of the network in the demise of the silence, but do not know where to do online, in addition to Google and Alibaba, do fire products more obvious website, products are; fire bags, fire Blocking materials and other products. Thank you so! I have a little points please Thank you so! More

- However, first of all you have to have a good domain name, or bad promotion

- Q: How is the distinction between fire grade?

- Look at how much concentration the concentration of the higher the better

- Q: Fire safety basic knowledge training content

- What is the name of the department?

- Q: Indoor to do with the gypsum board or good or good use of fire board board, fire board is made of what material ah how environmental

- Gypsum board can, low cost Of course the best for wood. Fire board is a particle board or density board paste the skin, which contains plastic, formaldehyde content of course, it is difficult to distinguish the quality of good or bad.

- Q: What is the fire insulation material

- Foam cement insulation board, a new type of fire insulation household 窢 cream drink Viagra pens Taiwan Gongjun material light weight, high fire performance, and the insulation effect is high-rise building exterior wall insulation excellent material.

- Q: Short point is to do hand copy

- The three conditions that trigger the fire are: combustible, oxidant and ignition energy coexist and interact. Explosive conditions are: explosives (containing reducing agents and oxidants) or combustibles (combustible gas, steam or dust) and air mixture and the initiation of energy at the same time, interaction. If we take measures to avoid or eliminate one of the above conditions, you can prevent the occurrence of fire or explosion, which is the basic principle of fire and explosion.

- Q: What is the meaning of the plastic raw material fire rating HB?

- HB level is not the meaning of fire.

- Q: How to brush fire paint

- First, the fire coating in the coating before the paint should be sufficient to stir the average, such as paint is too thick when the amount of water can be too concentrated to be painted, can not flow can be. Second, the choice of spraying methods need to select the specific circumstances, such as the construction of the tunnel is required to take the spray method of construction, although some paint waste but save manpower costs also shorten the construction time, but if the construction object is Indoor, you need to take the method of artificial smear brushing, not only can reduce the use of paint, but also to prevent the paint splashed to other places, to avoid the construction after the clean-up work. Third, the thickness of the coating requirements of the fire coating, the first time the thickness of the coating to cover the appearance of the base is appropriate, the individual does not exceed 1mm; in the previous coating before the practice can be carried out before the next painting; Increase the thickness of each brushing, but not flow is appropriate.

- Q: Plastic products in the classification of fire levels is how the standard ah?

- Flammability rating, that is, the material has or the material has been treated with a postponement of the nature of the flame spread, and the division of the system. 1, the plastic flame retardant grade from HB, V-2, V-1 to V-0 step by step increase: HB: UL94 and CSAC22.2No0.17 standard in the bottom of the flame retardant grade, requiring for 3 to 13 mm thick Sample, burning speed less than 40 mm per minute; less than 3 mm thick sample, burning speed less than 70 mm per minute; or 100 mm mark before extinguishing. V-2: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. There can be a burning thing falling. V-1: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. Can not have a burning thing falling. V-0: After two 10-second burn tests on the sample, the flame is extinguished in 30 seconds. Can not have a burning thing falling. 2, UL classification of plastic material burning grade? UL is the plastic material standard test piece after the flame burning after the spontaneous combustion time, spontaneous combustion speed, falling particles to determine the state of the burning of plastic materials, according to the level of good and bad, followed by HB, V2, V1, V0, 5V, There are very thin material grades VTM-0, VTM-1, VTM-2, and foam material grades HBF, HF-1, HF-2.

Send your message to us

Manufacturers produce borosilicate 3.3 heat-resistant glass(Microwave oven glass panel,glass tray)

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords