Cast Steel Centrifugal Pump Electric High Flow

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

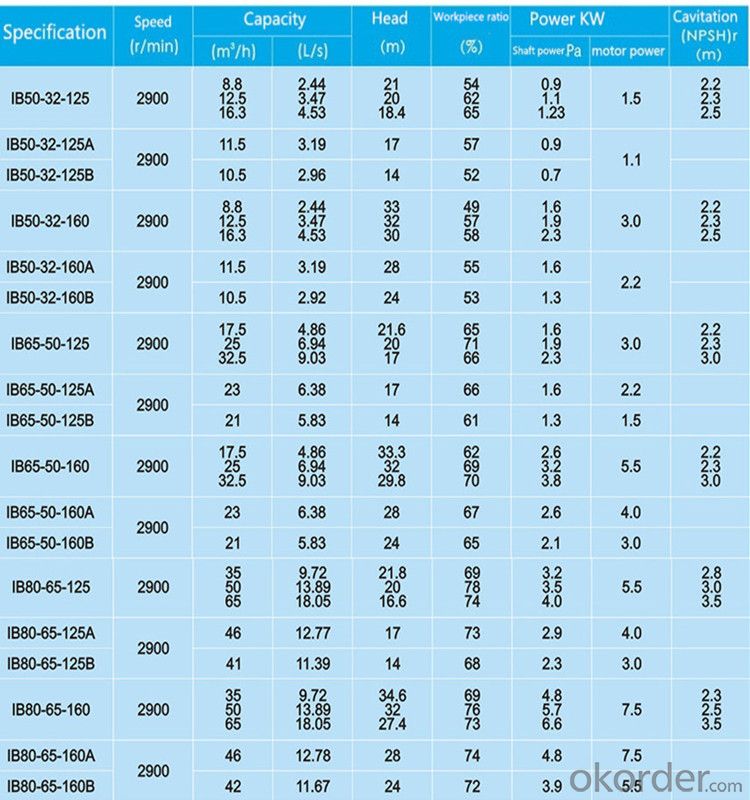

Specification

Company Introduction

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product specification

Application

Mainly apply to delivery sewage water ,waster water and rain water contains solids and

fibres:

*municipal project

*building construction

*residential area

*industrial sewage treatment

*eviroment protect

*mining

Features

1. Resistant to acid, alkali, wear and high temperature.

2. High mechanical strength, steady performance, good tightness.

3. Convenient operation and durable.

4. Be able to transport water that under the position it was installed. No need for filling liquid after the first time it was used.

Pictures show

Transportation

- Q: 1 water pump frequency converter constant pressure water supply wiring diagram

- This is a Fuji inverter, water pressure sensor, if it is remote pressure gauge, connect 11, 12, 13 ends, if the pressure transmitter 11 and C1 end

- Q: I want to know how to start up a water pump so i can move up to my camp.

- There's a few different kinds of water pumps. If you're referring to a hand-pumped well water pump that doesn't work, then it's generally lost it's prime. Some well pumps are constructed so you pour a quart or so of water into the pump and stroke the handle up and down until the water rises in the well. Other kinds of well pumps you have to take the hand pump off and pour a bucket of water into the well hole. It just depends on what kind of water pump you have.

- Q: I would like information to use an automotive water pump to ( or possibly another device ) to pump water approximately 60 feet (20 meters) elevation from creek without electricity. I only need enough water for 25 chickens. So we are not talking about a households supply of water.

- You need a lot more information than that. My first question is: how do you intend to operate a pump of any kind without electricity? Another piece of information needed for this is how far the chickens will be kept from the creek. Required change in elevation is a factor, but so is the length of pipe through which the water will be pumped. Pumping water farther leads to more energy lost due to friction which means you need a larger pump to maintain the same flow rate. Diameter and material of pipe is also a factor, along with bends and expansions/contractions. Since you don't need exact values for this... the flow rate required wouldn't even need to be 5 gal per day. That's just a trickle of water, so basically any pump capable of pumping water up 60 feet through however long your pipe (probably PVC) will be, would probably be enough to maintain drinking water for your chickens. That being said... if this is near your house, why don't you just run a water hose out there? Put a cap on the hose, drill a small hole in the cap and leave the valve to the hose turned on all the time. You could test it by seeing how long it takes to fill up a gallon or something...

- Q: My friend wants to buy a 90's somethin dodge avenger.( not sure what year) and the guy says the water pump is bad. Does the car have to be re timed when u replace the water pump?

- There is no connection between the water pump and the timing. Timing is a function of the engine ignition system, water pumps are part of the cooling system. There is no relationship. The water pump is driven by the belt that drives all the other engine accessories. Changing a water pump does not in any way effect timing.

- Q: What does water flow mean?

- The quantity of water produced per hour

- Q: My '95 Ford Ranger has had the sound of a bearing going bad in a pulley for about two months. Finally this weekend I started it up and it must have locked up, the belt was squealing really loud and snapped. So, now the water pump pulley has rubber chunks on it, which would make me think that is the bad pulley. But the pulley spins perfectly, really smooth. The alternator pulley on the other hand does not spin perfectly. It is not really hard to spin, but it does not spin smoothly. And the alternator pulley is real clean, no rubber on it at all. Any thoughts? I was thinking of buying a cheap belt and putting it on there, have someone start the truck and watch under the hood to see which is bad.

- Bad Alternator Pulley

- Q: i have just bought a coachman 1994 wanderer but water pump do`snt work,there are 3 wires to pump socket inside the van,white,red,yellow,only the white was fitted and reads 12v to earth,the other 2 read 6v to earth, any help as I cant find a wiring diagram on net !

- THREE HALFWITS DONT NO WHAT A CARAVAN IS

- Q: I have an ls vtec set up on my 89 EF si, I want to install a better oil and water pump. I m thinking of going with GSR. BUt my question is are all years gsr oil, water pump the same? I think my ls Block is from 93-95 acura. which year gsr water oil pump can I use for my motor?. also I have a 2000 si head. do I have to change the timing belt? and Last question is should I use b16, gsr type r pumps? I heard gsr and type r have the same part #. Thanks

- you need the GSR/Type-R water pump. This is one of the major causes of LS/VTEC failure. The GSR/Type-R has 22 teeth while the LS/GS has 19 teeth. The extra teeth cause it to spin faster pushing more water through the system. Any time you change something related that uses the timing belt, I ALWAYS install a new timing belt, and tensioner. That way there are no worries later.

- Q: In this area (picture) its leaking quite a bit of coolant underneath the car it is heavy dripping. Could it be the water pump? Car is over heating .It almost looks like its missing a screw or something where the coolant is dripping.

- Looks like it needs a thorough coolant flush and a water pump.

- Q: i got that special socket but everytime i try to loosen the pump going clockwise i can not get the pump to come loose the socket just slips off any suggestions these is a northstar engine

- The tool you need is the kent moore design one. it has a bracket that bolts on and helps hold that socket that you call it snug against the pump..one other thing look at the new pump to determine the direction it loosens because i do not remember,also we have only one tool and its worked on all northstar engines so far

Send your message to us

Cast Steel Centrifugal Pump Electric High Flow

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords