Stainless Steel Centrifugal Pump Electric High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Company Introduction

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Manufacturing process:

1.Stamping of lamination

2.Rotor die-casting

3.Winding and inserting – both manual and semi-automatically

4.Vacuum varnishing

5.Machining shaft, housing, end shields, etc…

6.Rotor balancing

7.Painting – both wet paint and powder coating

8.Motor assembly

9.Packing

10.Inspecting spare parts every processing

11.100% test after each process and final test before packing

Features

1. Hydraulic design with wide flow-path non-clogged structure ,allowed fibres(3 times

length of inlet diameter),particles(30% size of inlet diameter )

2. Excellent design,high efficiency and energy saving .

3. Double mechnical seals in series,made of hard alloy corrosive proof silicon

carbide,which is durable and .wearable ,that enable pump safely operation for more

than 8000 hours continous.

4. Compact structure, small volume, easy moved and conveniently mounted , no need build

pump house, greatly reduct the cost.

pump superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

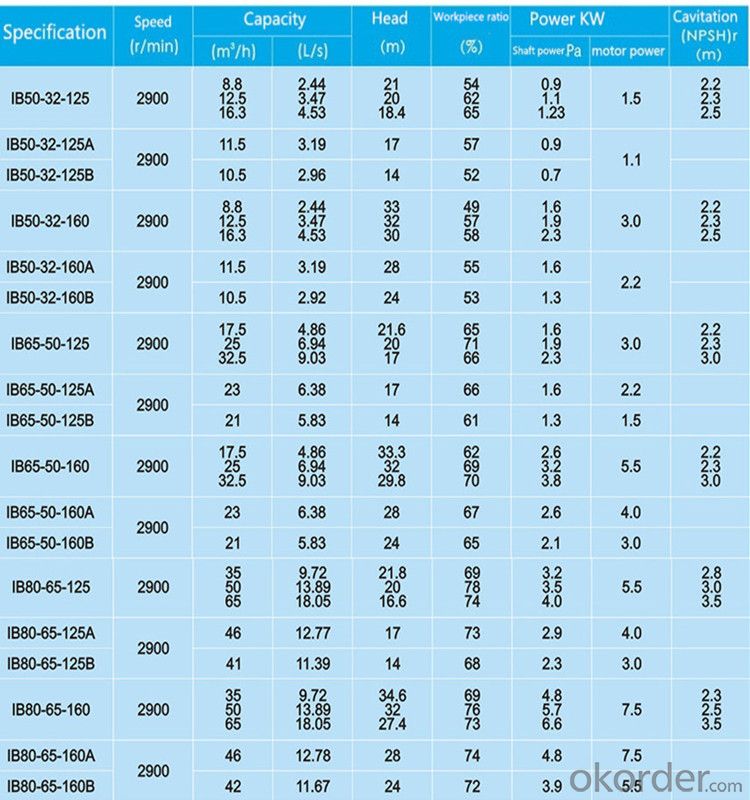

Product specification

Pictures show

Transportation

- Q: removed my water pump to replace it. i have the fan and clutch assembly still attached...i have no idea how to remove these...the fan clutch has bolts that hold the fan to it...and i did remove those but im just not sure how to separate this assembly...my water pump pulley has 4 holes...and no bolts so i presume it's pressed on...and there looks to be a very large nut between the pulley and the fan/clutch assembly...any help would be appreciated on this...i'd much rather go to the parts store w/ the old pump instead of guessing.....thnx in advance...

- The fan has a large nut that needs to unscrew off of the water pump. It is easiest to do that when pump is still on engine. It should be standard righthand thread.

- Q: ive just replaced my water pump as i know it wasnt in good shape and was a big cause of my problems. but the new water pump also seems to make a noise once in a while like its dry and there isnt anywater or its having a hard time. the head is good and has an extra thick headgasket on it. my guess is i have a clogged radiator and it would sound reasonable as i have used head gasked sealant in the radiator and it has prob clogged parts of it. the other symptom is afater about 4 hrs of continuous driving it starts to over heat if im doing 70 bor more but if i drop back down to 65 it seems to stable out or in many cases go down all together. anyone else had thes symptoms. and will a water pump make noise if there isnt anywater to pump.

- what is the 22r fitted in as most run a thermo fan assy which is fitted to the front of the water pump if you have this then most likely the thermo is either just about to seize or it's still turn's then its in freewheel mode the best way to check is when the motor is cold check and se if you have a thermo fan fitted if so out one blade at 12 oclock and spin with one hand if the blade goes down past 3 oclock then you will need to open the coupling this is a simple job you will see 8 phillips head screws remove all and crack open the coupling but before this is done go to your local toyota dealer and purchase 1x 08816 10001 silicone empty this into the coupling and close this will fix your problem

- Q: I would like information to use an automotive water pump to ( or possibly another device ) to pump water approximately 60 feet (20 meters) elevation from creek without electricity. I only need enough water for 25 chickens. So we are not talking about a households supply of water.

- I agree, the bucket sounds like a better idea, but if you're intent on using a pump, try this. There are several manufacturers who make small (about the size of a coffee mug) portable pumps that hook to garden hoses, and run off of drill power. You can use a cordless drill, so you don't need power at the pump. The pumps are a few dollars, and available at most old fashioned hardware stores. Try Sears. I've also seen an old style hand pump fitted with a garden hose fitting. You can rig a bracket to hold the pump over the water, with the inlet in the water, and use muscle power to pump the water to your chickens. No idea where to buy it though. I hope that helps

- Q: i want details and requirement of it in water pump

- For the best answers, search on this site https://shorturl.im/awBzE A very good foot valve will cost about $20 then it will be the cost of a service call, here we charge about $70 but depending on where you live, how deep the valve is and where its located the price maybe different, and the cost maybe more on a weekend too. Giving quotes for this is not really profitable for service companies, so if you are not prepared to do it yourself then you will have to pay the service call rate. A good reputable company will arrive at your home and give you an approximation on what it will cost, but remember once you call them there you will probably have to pay the service call rate, if you are running tight on money call around and ask the rates but remember that this is a weekend and most companies will be running a small crew and might take time to answer your call. The other option is since you have changed the pump yourself why not just change the foot valve your self? Have you primed the pump after replacement? To replace the valve the pipe that runs to the bottom of your well must be pulled up and the valve is on the bottom of it, its a simple matter of removing the old one and replacing with new the big job is usally the pulling up of the pipe.

- Q: honda acord water pump 1988

- hello Purchase a how to book, because part of the water pump sits behind the timing belt cover.Hope this was some help.

- Q: my water pump went bad on my 1997 chevy cavalier, causing it to leak all the coolant it had in the system. i put water in it til i could get new water pump. changed out water pump. attempted getting air out of system. put more concentrated coolant in system than i did water. bad guessing on my part. ran car around block 5 times. it was fine. this morning on the way to work, it started overheating again. my thoughts : more air in system that's not coming out? thermostat REALLY went bad at same time as water pump???? overheating all because of a little too much coolant??? for some crazy reason, my system needs to be suddenly flushed? Your thoughts? one last thing, the car has always ran perfectly normal temp til water pump went bad.

- Check your radiator,check your radiator fan to see if it works! Sometimes they go bad or their sensor won't work anymore and the car is overheating the sensor doesn't pick that up and the fan won't start! That's make the car overheating!

- Q: first off i should say it is below freezing here....with that said, the water pump pulley is not turnning so.. the fan belt busted which leads me to believe the water pump is frozen...... right?i am currently traveling and have little money to spend on a new water pumpis there any way that anyone may know to dethaw a frozen water pump without damaging it?... i should say, the motor is running great, no cracks or leaks from the cold.

- dethaw LOL! That would mean freeze it right? Apply heat to thaw.

- Q: i have a significant stream of water running out of the coolant return side of the engine under the coolant pipe on a 1997 caravan i will lose a gallon and then it stops until the engine heats up and of course more comes out with expansion

- You will have to remove the AC compressor, all of the drive belts, alternator bracket, power steering pump and bracket, motor mount, timing cover, and the timing belt. This job calls for 4.3 hours and I was able to do one in about 3. If you really want to attempt this yourself, let me know and I will give you detailed step by step instructions to do it, right down to the timing marks and what size each bolt is. If you have never done a water pump/timing belt on any car before, I strongly recommend you don't attempt this repair yourself. The 3.0 really isn't a bad one to do, if you have the tools and some mechanical knowledge and ability.

- Q: 37KW how many contactors does the pump need to start directly?

- First of all, you have to see what voltage you use If 380V then current per KW is about 2A, if it is 660V per KW at about 1.1A, then it is the starting current is 3 to 7 times for the starting current, but for the moment, 380V voltage: 37*2=74A 100A on the line, 660V voltage: 37*1.1=40.7A 63A on the line.

- Q: There is a 5.5KW before the pump head is now 25 meters and flow of 20 cubic meters, but not up to the requirements, I think this is like with a motor pump, lift more than 20 meters, the flow is about 40 cubic meters of water pump, please inform the models and parameters, thank you

- Model has: QS-250-40-21, lift 21m, flow 40 square, motor power is 4KW, water pump diameter is 232cmQJ-200-40-26, lift 26m, flow 40 square, motor power is 5.5KW, water pump diameter is 189cmYou can choose the right pump according to your well path.

Send your message to us

Stainless Steel Centrifugal Pump Electric High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords