HVAC Aluminum Coils - Alloy 1050, 1100, 3003 Mill Finish Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

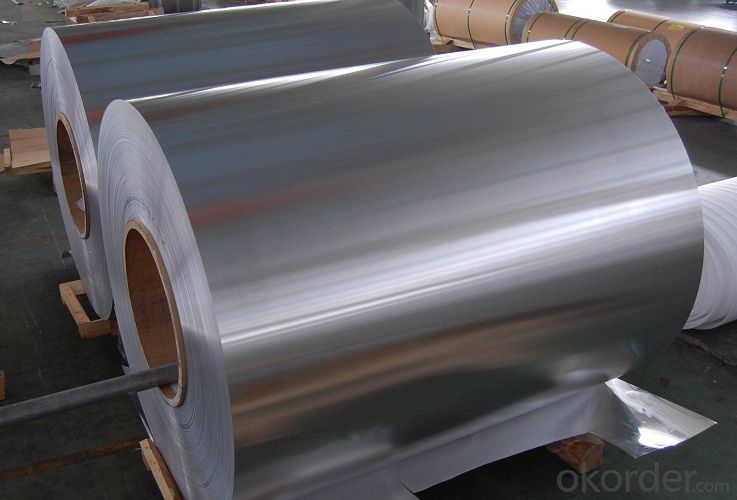

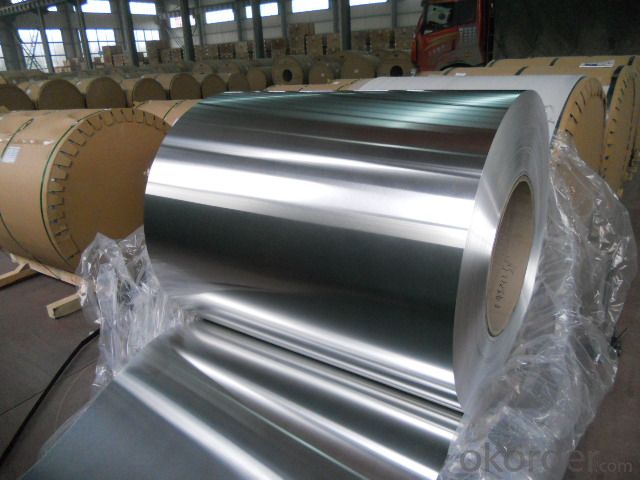

Alloy 1050,1100, 3003 Mill Finish Aluminum Coil

l Product Introduction

Aluminium Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification

Perforated/Slitting Mill Finish Aluminum Strip Coil | |

Grade and Temper | Alloys: 1050, 1100, 3003, 3004 3005, 3105, 5005, 5052, 6061,6083, 8011,etc Temper: 0-H112 |

Widths | 35mm – 2,450 mm available |

Thickness | 0.09mm – 150mm |

Treatment | Mill Finish |

Coil Specifications | I.D.: 405mm, 505mm O.D.: 800mm - 1270mm |

Packing Detail | Wooden pallet either eye to wall or eye to sky |

Application | Perforated Aluminum Ceiling Panel, Conner Bead, sifter for mechanical equipment and Fencing, etc. |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q:Can aluminum coils be used for roofing applications?

- Yes, aluminum coils can be used for roofing applications. Aluminum is a popular choice for roofing due to its lightweight nature, durability, and resistance to corrosion. It is commonly used for both residential and commercial roofing projects.

- Q:How are aluminum coils stored in a warehouse?

- Aluminum coils are typically stored in a warehouse in a way that ensures their protection and easy accessibility. The coils are usually stacked in rows, either vertically or horizontally, depending on the available space and the weight of the coils. To prevent damage and maintain their shape, the coils are often stored on pallets or racks that provide support and stability. Additionally, the coils may be wrapped in protective materials such as shrink wrap or plastic sheets to shield them from dust, moisture, and other potential hazards. Proper labeling and organization are also crucial to facilitate inventory management and efficient retrieval. Overall, the goal of storing aluminum coils in a warehouse is to maximize space utilization, minimize the risk of damage, and ensure their readiness for shipment or further processing.

- Q:What are the potential applications of coil-anodized aluminum coils?

- Coil-anodized aluminum coils possess unique properties and advantages, allowing them to be employed in a wide range of potential applications. Here are some of the primary areas where they can be utilized: 1. Architectural: The distinct properties of coil-anodized aluminum make it well-suited for architectural purposes, including cladding, roofing, and facades. With its anodized coating, it offers increased durability, resistance to weather conditions, and color stability, making it suitable for outdoor use in various climates. Furthermore, the coils can be shaped and formed to create different architectural elements, providing design flexibility. 2. Transportation: Due to its lightweight nature, coil-anodized aluminum is ideal for transportation applications. It can be employed in the manufacturing of parts and components for the automotive, aerospace, and marine industries. The anodized coating enhances its corrosion resistance, making it suitable for exterior components and structures. 3. Electronics: Coil-anodized aluminum coils find utility in the field of electronics manufacturing. The anodized coating provides excellent electrical insulation, which is crucial in applications necessitating high conductivity and insulation. It can be utilized in the production of components such as heat sinks, casings, and connectors. 4. Signage and displays: The vibrant and long-lasting colors achieved through coil-anodizing make it a perfect material for signage and displays. The anodized coating ensures color stability against UV radiation and harsh weather conditions, rendering it suitable for both indoor and outdoor applications. It enables the creation of eye-catching and durable signage and displays. 5. Furniture and interior design: Coil-anodized aluminum coils can be employed in the manufacture of furniture and interior design elements. The anodized coating provides a smooth, durable, and scratch-resistant surface, making it suitable for applications like tables, chairs, wall panels, and decorative elements. The wide range of available colors and finishes allows for versatile design possibilities. 6. Industrial applications: Coil-anodized aluminum coils can be utilized in diverse industrial sectors. The anodized coating offers enhanced corrosion resistance, which is advantageous in industries such as chemical processing, food processing, and pharmaceuticals. It can be used in the production of tanks, containers, and equipment that require resistance against harsh chemicals and environments. 7. Energy and sustainable applications: The lightweight nature and durability of coil-anodized aluminum make it suitable for energy and sustainable applications. It can be employed in the manufacturing of solar panels, heat exchangers, and other energy-related components. The anodized coating provides protection against weathering and corrosion, ensuring long-term performance. In conclusion, coil-anodized aluminum coils have extensive and diverse potential applications, spanning across architectural, transportation, electronics, signage, furniture, industrial, and energy sectors. The combination of its lightweight nature, durability, color stability, and corrosion resistance makes it a versatile material for various industries and applications.

- Q:Why does it take less energy to get aluminum metal from used cans than to get it directly from the ore?

- in order to extract the raw aluminum, you have to heat everything and melt it first, then remove the stuff that precipitates out as it cools or forms via chemical reaction with catalysts you introduce. With aluminum cans, you don't have to raise the temperature much above the melting point of aluminum, since it's already the substance in the can with the highest melting point. With aluminum ore, there can be anything in the ore with pretty much any melting point. In particular, if the ore contains an alloy of aluminum and a metal with a higher melting point than aluminum, then rest assured, you will have to raise the temperature of the ore above the melting point of aluminum in order to melt that alloy, In any case, because the maximum required temperature of the smelter needed to melt used aluminum cans is necessarily lower than the maximum temperature required to work with the ore, less energy is required to get aluminum from used cans than from ore.

- Q:Can aluminum coils be used in high-humidity environments?

- Indeed, high-humidity environments can accommodate the use of aluminum coils. Due to its corrosion-resistant nature, aluminum proves to be a fitting material for areas with elevated humidity levels. The formation of a natural oxide layer on the aluminum surface acts as a safeguard against moisture, effectively warding off rust and corrosion. Hence, aluminum coils are widely favored for HVAC systems, as they encounter regular exposure to moisture and humidity. Moreover, the lightweight, durable, and exceptional heat transfer properties of aluminum coils render them an optimum selection for a multitude of industrial and commercial applications in high-humidity settings.

- Q:How are aluminum coils used in the production of medical equipment?

- Aluminum coils are widely used in the production of medical equipment due to their unique properties and versatility. One of the primary applications of aluminum coils in the medical industry is in the manufacturing of various medical devices, such as MRI machines, X-ray machines, and ultrasound equipment. Aluminum coils are utilized in the production of medical equipment mainly because of their excellent conductivity. This property allows them to efficiently conduct and dissipate heat, which is crucial for the proper functioning of medical devices. For instance, MRI machines generate a significant amount of heat during operation, and aluminum coils help in regulating and maintaining the desired temperature to ensure optimal performance and patient safety. Moreover, aluminum coils are also highly malleable and can be easily formed into different shapes and sizes. This makes them ideal for the production of medical equipment, where intricate designs and precise specifications are often required. For example, aluminum coils are used in the construction of radiation shields, which protect medical personnel and patients from harmful radiation emitted by X-ray machines. In addition, aluminum coils are lightweight yet durable, making them an excellent choice for medical equipment that needs to be portable or easily maneuvered. This is particularly important for devices like portable ultrasound machines, where lightweight components are necessary for ease of use and transportation. Furthermore, aluminum coils have excellent corrosion resistance, which is vital in the medical field where cleanliness and hygiene are of utmost importance. The resistance to corrosion helps in preventing the buildup of bacteria, germs, and other contaminants on the surface of medical equipment, ensuring a safe and sterile environment for patients and healthcare professionals. Overall, aluminum coils play a crucial role in the production of medical equipment by providing properties such as conductivity, malleability, lightweight, durability, and corrosion resistance. These properties allow for the efficient and safe operation of medical devices, contributing to improved patient care and well-being.

- Q:Can aluminum coils be used in telecommunications infrastructure?

- Yes, aluminum coils can be used in telecommunications infrastructure. Aluminum is commonly used in various components of telecommunications infrastructure, including cables, connectors, and antennas. It is preferred for its lightweight, durable, and corrosion-resistant properties, making it suitable for outdoor installations. Additionally, aluminum coils provide excellent conductivity, ensuring efficient transmission of signals in telecommunications systems.

- Q:Are aluminum coils recyclable?

- Indeed, recyclability applies to aluminum coils. As one of the most easily recyclable substances, aluminum can be recycled ceaselessly without compromising its integrity. The process of recycling aluminum coils entails melting them down to create fresh coils or alternative aluminum goods. This practice not only diminishes landfill waste but also conserves energy and resources necessary for manufacturing new aluminum from primary materials. Opting for the recycling of aluminum coils is an environmentally conscious decision that aids in the preservation of natural resources and the mitigation of greenhouse gas emissions.

- Q:Can aluminum coils be used in the production of aluminum downspouts?

- Yes, aluminum coils can be used in the production of aluminum downspouts. Aluminum coils are typically made from high-quality aluminum alloy and are rolled into thin sheets. These coils can then be cut and formed into various shapes and sizes, including downspouts. Aluminum is a popular choice for downspouts due to its lightweight, durable, and corrosion-resistant properties. Additionally, aluminum coils can be easily manipulated and shaped to meet specific design requirements, making them suitable for manufacturing aluminum downspouts.

- Q:What do you think of the stainless steel with copper and aluminum core cookware? And what's a good brand?

- Plastic! High temperature plastic! The inside is coated with Teflon a high temp polymer and the outside is aluminum foil. Take the cookware, tip it upside down and spray it with Rustoleum copper tone and presto, you have the cooper bottom like Revere Wear. When you are done after being careful to cook only low temp foods, throw it away thus eliminating the chores of doing dishes and practicing going green with no water used. Oh, by the way, the name of this cookware is Flash-in-The Pan!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HVAC Aluminum Coils - Alloy 1050, 1100, 3003 Mill Finish Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords