Cold Rolled Steel Coil price shipping from china

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 65450 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The raw material of cold rolled steel coil/sheet is high quality hot rolled product.

Cold rolled steel coil/sheet as defined in the EN 10130/98 standard, with guaranteed maximum mechanical characteristics and guaranteed minimum ductility and formability.

It is suited to formation by bending or drawing, which enables complex parts to be produced in good repeatable conditions and intended for indoor use.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF (non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Pictures of Cold rolled steel coils

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

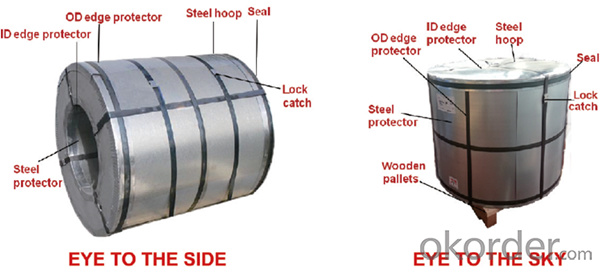

Packing:

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;

We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC.

We will arrange the factory manufacturing as soon as possible.

The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: What products can we make with steel (eg Steel strip, rod, bar, rail, tube) How are these made? What can we make from these steel products?Can you please make the answers as detailed as possible you can because i really want to know this really well. Thank you.

- Your okorder (they make steel deck and steel joists) There are thousands of other items routinely produced from steel, including rebar, and all the metal in cars, airplanes, and about a million other things.

- Q: What are the different types of coil leveling machines?

- There are several different types of coil leveling machines used in various industries. Some of the most common types include: 1. Precision Roll Levelers: These machines are highly accurate and capable of leveling coils with high precision. They use a series of rolls to apply pressure and remove any distortions or imperfections in the coil. 2. Straighteners: Straighteners are used to flatten coils that have become curved or warped during the manufacturing process. They typically consist of a set of rollers that gradually bend the coil in the opposite direction to restore its flatness. 3. Rotary Levelers: Rotary levelers are used to level coils that are thicker or have a higher yield strength. They utilize a series of rolls that rotate in opposite directions to apply pressure and flatten the coil. 4. Tension Levelers: Tension levelers are commonly used for leveling thin-gauge coils. They work by applying tension to the coil while passing it through a series of rollers. This process helps to remove any waviness or unevenness in the coil. 5. Stretch Levelers: Stretch levelers are specifically designed to level coils made of high-strength materials. They use a combination of stretching and bending to remove any irregularities in the coil's surface. 6. Cut-to-Length Lines: These machines not only level the coil but also cut it into specific lengths as per the customer's requirements. They are commonly used in industries where precision and customization are essential, such as automotive or construction. Overall, the choice of coil leveling machine depends on factors such as the type and thickness of the coil, desired level of accuracy, and the intended application of the leveled coil.

- Q: Several reading methods of steel tape measure

- Precise steel tape factory and after a period of time must go through the verification and indicate the verification of temperature, tension and feet. Feet marked on the length of its nominal length, and the difference between the actual length is called length correction delta l ruler by different tension will make feet long. To avoid this change requires the use of steel tape according to the scale mark force of steel tape. At different temperature the foot will change with the temperature so it is necessary to use t as variable function to represent the feet long, this is the ruler length equation, its general form:

- Q: What is the minimum diameter of a steel coil?

- The minimum diameter of a steel coil can vary depending on the specific requirements and manufacturing processes, but it is typically around 4 inches or 100 millimeters.

- Q: What are the different grades of steel used for coils?

- The different grades of steel used for coils vary depending on the specific application and requirements. Some common grades include low carbon steel (C1008/1010), medium carbon steel (C1045), high carbon steel (C1070/1095), stainless steel (304/316), and advanced high-strength steels (AHSS) like dual-phase (DP), transformation-induced plasticity (TRIP), and martensitic (MS). Each grade offers different properties such as strength, corrosion resistance, formability, and weldability, allowing manufacturers to choose the most suitable grade for their coil production.

- Q: is cold roll or hot roll mill roller is cast steel? or cast iron?

- another name is Grey iron, come from groups of ferrous alloys

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are processed and shaped into long sections known as rails. These coils are first uncoiled and then heated, allowing them to be rolled and formed into the desired rail shape. The resulting rails are then cut to the required length and undergo further processes such as straightening and finishing to ensure their strength, durability, and suitability for use in railways.

- Q: How do steel coil manufacturers manage inventory?

- Steel coil manufacturers manage inventory by implementing various strategies and techniques. Firstly, they maintain a robust forecasting system to accurately predict demand and plan production accordingly. This helps in avoiding overproduction or stockouts. Additionally, they establish strong relationships with suppliers to ensure a steady supply of raw materials and reduce lead times. Inventory is carefully monitored using inventory management software, which tracks stock levels, identifies slow-moving or obsolete inventory, and enables timely reordering. Just-in-time (JIT) or lean manufacturing techniques are often employed to minimize inventory holding costs. Lastly, regular inventory audits and analysis are conducted to identify areas for improvement and optimize inventory levels for maximum efficiency and profitability.

- Q: I wrote in my assignment that mild steel has a high carbon content (4%).This is why it has its strong and rigid properties.. is this correct?

- High carbon steel is much harder than iron. In fact, steel -is- iron with carbon in it. Mild steel has a very low carbon content and is much softer. High carbon steel is much stronger after heat treatment. However, about 2% carbon, it is considered cast iron. Mild steel contains about 0.16% to 0.29% carbon content. It has a relatively low strength but is highly malleable.

- Q: What are the common transportation defects in steel coils?

- Steel coils can experience various transportation defects. Improper handling or securing during transportation is a major cause of coil damage, resulting in dents, scratches, or tears in the steel. Coil edge damage is another issue that arises when the coils lack proper protection or rub against each other during transit, leading to deformation or breakage of the edges. Additionally, coil shifting occurs when the coils are inadequately secured or braced, causing them to move and shift during transportation, potentially causing misalignment or damage. Moreover, coil corrosion is a prevalent defect that arises when the coils are exposed to moisture or corrosive elements during transportation, leading to rust and deterioration of the steel. To prevent these common transportation defects in steel coils, it is essential to implement appropriate handling, securing, and protection measures.

Send your message to us

Cold Rolled Steel Coil price shipping from china

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 65450 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords