Fiberglass Mesh for Stucco - E-Glass Fiberglass Marble Mesh for Buildings and Wall

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E-glass Fiberglass Marble Mesh for Buildings and Wall

Definition of E-glass Fiberglass Marble Mesh

E-glass Fiberglass Marble Mesh is mainly alkali-resistant fiberglass fabric. Fiberglass Mesh mainly use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. Fiberglass Mesh is an ideal engineering material in construction and decoration industry.

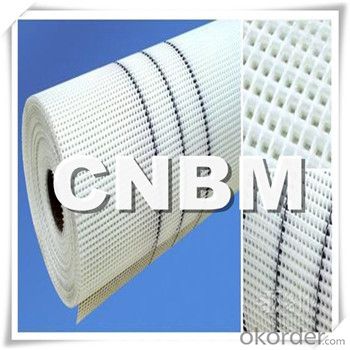

Image of E-glass Fiberglass Marble Mesh

Application/Usage of E-glass Fiberglass Marble Mesh

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement Fiberglass Mesh, Electrical heating mats Fiberglass Mesh

Marble slab reinforcement / Mosaic carrier Fiberglass Mesh, Asphalt reinforcement (roof water-proof) Reinforced lightweight construction boards Fiberglass Mesh.

E-glass Fiberglass Marble Mesh Production Process

Application :

Package: E-glass Fiberglass Marble Mesh are packed in shrink-wrapped, then put into cartons or pallets.

Packing volumes: about 20000m/20FCP, 40000m2/40HQ.

Delivery: About 15 days after confirming the order.

FAD:

Q: What is the storage of Fiberglass Mesh?

Store Fiberglass Mesh out of direct sunlight, away from direct contact ground or concrete;

Store Fiberglass Mesh rolls in cool, dry location, away from weather or other damage.

Q: What is the guarantee period of Fiberglass Mesh ?

Fiberglass Mesh: Four years under normal weather conditions and usage directions.

Q: What is the Advantage of Fiberglass Mesh ?

Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

Good dimensional stability & positioning property, stiffness, smoothness an difficult to shrink & deformation.

Good impact resistance and not easy to be teared.

Q: Why choose our CNBM Fiberglass Mesh?

We are the manufacturer of Fiberglass Mesh, price will be reasonable and much competitive

We have produced Fiberglass Mesh strictly in according to customers' detailed requirements

CNBM Fiberglass Mesh theme is: Good Quality, High Credibility & Best Service.

- Q:Why does the construction sector have no supervision on the use of fiberglass mesh?

- External thermal insulation needs a large amount of fiberglass mesh.

- Q:Should gridding cloth be added when painting the inside corner of infilled wall and concrete column or shear wall?

- The square staff of inside corner must be added.

- Q:Does the new house wall need to paste mesh?

- It depends on the situation of wall flatness and the base wall, the general commercial residential semi-finished building is not needed

- Q:What is the difference between alkali resistant fiberglass gridding cloth and glass fiber gridding cloth?

- Actually they both are called glass fiber gridding cloth?

- Q:Is glass fiber harmful to human body?

- Skin damage: glass fiber workers have contact dermatitis, but some workers can gradually tolerance, known as "hardening" phenomenon. The extent of skin damage depends on fiber diameter and surface roughness. It is now accepted that fiber diameter exceeds 5 mu m, which has a significant stimulating effect. A small number of people exposed to glass fiber and rock wool have skin allergies, but so far they have not been proved to be allergens.

- Q:Should the wall shear walls be hung with fibre nets?

- The role of fiber networks:Cement concrete special reticular fiber into concrete, the concrete mixing process, fiber through the lateral connections between concrete self rubbing and friction role and destroy the formation of monofilament or reticular structure fully open, in order to achieve a large number of polypropylene filament plays on crack effect. The special mesh fiber of cement concrete can effectively control the micro cracks caused by plastic shrinkage, shrinkage and temperature changes of concrete, and prevent and control the formation and development of cracks. As a new kind of anti cracking fiber for concrete, concrete mesh fiber with cement concrete is becoming the focus of research and application of fiber reinforced concrete after glass fiber and steel fiber.

- Q:How to use gridding cloth tape, namely glass fiber self adhesive tape?

- 1. Keep the wall clean and dry. 2. Paste and press the tape on the crack. 3. Confirm that the gap has been covered with tape, and then cut the needless tape and paint with mortar. 4. Allow it to dry naturally, then polish gently. 5. Fill enough paint in and make its surface smooth. 6. Cut the leak-out tape. Then, check if all the cracks have been properly patched, and decorate the crack with subtle composite material to make it look clean and new.

- Q:What is the difference between carbon fiber and glass fiber

- The chemistry is quite differentCarbon fiber (Carbon Fiber) is made of carbon fiber treated and graphite epoxy coating fabric of the pressure. The utility model has the advantages of light weight, high tensile strength, low density in all synthetic handle materials, carbon fiber is probably the most strong. Carbon fiber is a kind of highly processed materials, so the general is also used in high-end products.

- Q:Mesh cloth and Dacron cloth, which one is better?

- I think Dacron is better. If it is light wall, and if allowed, you can also use wallpaper to cover the spots.

- Q:When plastering walls, can alkali-resistant fiberglass mesh be replaced by galvanized steel mesh?

- Before puttying in the stage of decoration, alkali-resistant fiberglass mesh is used to prevent the surface putty from cracking. The price is too large. When the plasterign thickness is equal to or more than 35mm, galvanized?steel?mesh is needed. It wastes too much and it's not easy to operate. Galvanized steel mesh is generally used in the stage of cement mortar whitewashing wall.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Mesh for Stucco - E-Glass Fiberglass Marble Mesh for Buildings and Wall

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords