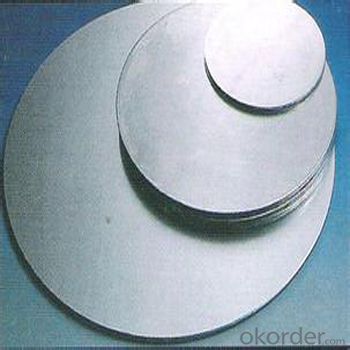

Aluminium Circle and Circles Round Shape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

Aluminium foil is produced by rolling sheet ingots cast from molten billet aluminium, then re-rolling on sheet and foil rolling mills to the desired thickness, or by continuously casting and cold rolling. To maintain a constant thickness in aluminium foil production, beta radiation is passed through the foil to a sensor on the other side. If the intensity becomes too high, then the rollers adjust, increasing the thickness. If the intensities become too low and the foil has become too thick, the rollers apply more pressure, causing the foil to be made thinner.

The continuous casting method is much less energy intensive and has become the preferred process.For thicknesses below 0.025 mm (1 mil), two layers are usually put together for the final pass and afterwards separated which produces foil with one bright side and one matte side.The two sides in contact with each other are matte and the exterior sides become bright, this is done to reduce tearing, increase production rates, control thickness, and get around the need for a smaller diameter roller.

2.Specification

ALLOY:AA1***(AA1050,AA1070,AA1100etc)

AA3***(AA3003 etc)

TEMPER:O,H14

THICKNESS:0.5mm-4mm

DIAGONAL:100mm-1200mm

STANDARD:GB/T 3880-2006

Special specification is available on customer's requirement

3.Why you can choose us?

We can supply you best quality and price!

4.Pictures

5.FAQ:

1)what is aluminum?

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

2)What's kind of payment term we can supply?

CIF,CFR, FOB and other.

3)Can we supply samples?

Yes, we can!

- Q:Are 101 aluminum sheets suitable for automotive applications?

- Yes, 101 aluminum sheets are suitable for automotive applications. 101 aluminum is a high-strength alloy that offers good formability, corrosion resistance, and excellent weldability. These properties make it a popular choice for various automotive components such as body panels, heat shields, and structural parts. Additionally, 101 aluminum sheets are lightweight, which helps improve fuel efficiency and overall vehicle performance. Overall, 101 aluminum sheets are well-suited for automotive applications due to their strength, formability, corrosion resistance, weldability, and lightweight characteristics.

- Q:What is the weight of an aluminum sheet?

- The weight of an aluminum sheet can vary depending on its dimensions and thickness. Aluminum is a lightweight material, so sheets made from it generally have a relatively low weight compared to other metals. To determine the weight of an aluminum sheet, you would need to know the length, width, and thickness of the sheet. By multiplying the dimensions and the density of aluminum (2.7 g/cm³ or 0.0975 lb/in³), you can calculate the approximate weight of the sheet.

- Q:What is aluminium oxide sheet?

- Brief introduction:Advantage:(1) good processing: anodized aluminum decorative strong, moderate hardness, easy bending forming, continuous high-speed, convenient and direct processing into products, no need for complicated surface treatment, greatly shorten the production cycle and reduce production cost.(2) good weather resistance: standard thickness of oxide film (3 m) anodized aluminum plate, indoor use for a long time, no discoloration, no corrosion, no oxidation, no rust. Anodized aluminum oxide film (10 m) can be used outdoors, and can be exposed to sunlight for a long time without discoloration.(3) strong sense: the metal surface of aluminum anodic treatment of high hardness, as gem, scratch resistance, surface is not covered with paint, keep aluminum metal color, highlight the modern sense of metal, improve product quality and added value.(4) high fire resistance: pure metal products, the surface without paint and any chemical substances, 600 degrees high temperature does not burn, does not produce toxic gases, fire protection and environmental protection requirements.(5) strong dirt resistance: no fingerprints, no stain marks, easy cleaning, no corrosion spots.(6) applicability: it is widely used in metal aluminum ceiling, curtain wall board, aluminum plastic panel, fireproof board, honeycomb aluminum plate, aluminum veneer, electrical panel, cabinet panel, furniture panel and so on.

- Q:Are 101 aluminum sheets suitable for heat exchangers?

- No, 101 aluminum sheets are not suitable for heat exchangers. Heat exchangers require materials with good thermal conductivity and corrosion resistance. While aluminum is a good conductor of heat, 101 aluminum alloy does not possess the necessary corrosion resistance properties required for heat exchangers. Other aluminum alloys, such as 3003 or 5052, are commonly used for heat exchangers due to their excellent thermal conductivity and resistance to corrosion.

- Q:What are the different surface finishes for aluminum sheets in the automotive industry?

- The different surface finishes for aluminum sheets in the automotive industry include mill finish, anodized finish, and painted finish. Mill finish refers to the untreated surface of aluminum sheets, which typically has a matte appearance. Anodized finish involves an electrochemical process that creates a protective layer on the surface of aluminum, enhancing its resistance to corrosion and increasing its durability. Painted finish involves applying a layer of paint onto the aluminum sheet, providing both aesthetic appeal and additional protection against the elements.

- Q:How do aluminum sheets perform in terms of wear resistance?

- Aluminum sheets generally offer good wear resistance due to their inherent properties and surface characteristics. Aluminum is a lightweight yet durable material that exhibits a high strength-to-weight ratio, making it suitable for various applications where wear resistance is required. The wear resistance of aluminum sheets can be further enhanced through various methods such as alloying, heat treatment, and surface treatments. Alloying elements like copper, magnesium, or zinc can be added to aluminum to improve its hardness and wear resistance. Heat treatment processes like precipitation hardening can also increase the strength and wear resistance of aluminum sheets. Furthermore, surface treatments such as anodizing or applying protective coatings can significantly enhance the wear resistance of aluminum sheets. Anodizing forms a protective oxide layer on the surface of aluminum, providing increased resistance to abrasion, corrosion, and wear. Coatings like powder coatings or paint can also provide an additional layer of protection against wear and tear. In terms of specific applications, aluminum sheets are commonly used in industries such as automotive, aerospace, construction, and marine due to their excellent wear resistance. They are utilized in components that experience sliding, rubbing, or impact, such as panels, body parts, and structural elements. Overall, while aluminum sheets may not possess the same level of wear resistance as certain steel alloys or other specialized materials, they offer a good balance between strength, weight, and wear resistance. With appropriate alloying, heat treatment, and surface treatments, aluminum sheets can provide satisfactory wear resistance in a wide range of applications.

- Q:For my chem class that I just barely started taking, we're making bohr models. Even though my teacher explained it, I still dont get the concept of it all, like how the protons are lined up in their inner circle and the outer circles. I get everythign else about atoms except how they're actually made up lol. Maybe someone on here can explain it to me? I hope so because i have to make a model for it for friday.The element I'm asigned is aluminum btwYour help is greatly appreciated!

- People also rarely display the vast space between the orbitals and the nucleus. That would be a good one. If it is aluminum that you are showing, Why not make it out of aluminum? Hope this helps.

- Q:What are the different forms of aluminum sheet available?

- There are several different forms of aluminum sheet available, including plain, embossed, perforated, and painted aluminum sheets.

- Q:Which kind of glue is best for bonding wood and aluminum sheet together?

- You can use 502 adhesive.

- Q:I am using Reeves Acrylic Colour Set and I plan on painting on Heavy Duty Ralphs Brand Aluminum Foil. Will the paint be able to go on the foil well? Tips? Thank you.

- i use aluminum foil to mix colors on and when it dries it DOES stick, however, it will scratch off really easy. just try experimenting. what do u need the foil for? maybe you can try the aluminum foil leaves? the flakes that you put ontop on the art instead of under it. that way you can glue it on and dont have to worry about it scratching off. foil looks beautiful on paintings :) how it turns out great

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Circle and Circles Round Shape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords