All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

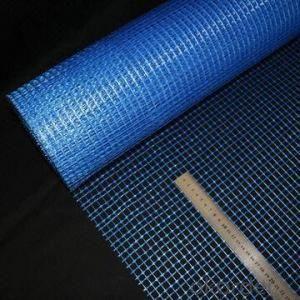

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

What are the different types of fiberglass materials available?

There are several types of fiberglass materials available, including E-glass, S-glass, C-glass, and AR-glass. E-glass is the most common type and is known for its versatility and affordability. S-glass, on the other hand, is stronger and stiffer than E-glass, making it suitable for applications requiring high strength. C-glass is corrosion-resistant and often used in water and chemical environments. Lastly, AR-glass, or alkali-resistant glass, is designed to resist degradation from alkali substances and is commonly used in cement-based applications.

Is fiberglass resistant to UV radiation?

Yes, fiberglass is generally resistant to UV radiation.

What are the different types of fiberglass repair kits available?

There are several different types of fiberglass repair kits available, including gelcoat repair kits, resin repair kits, and patch repair kits. Gelcoat repair kits are specifically designed to fix surface damage to the outer layer of fiberglass, such as scratches or gouges. Resin repair kits are used to repair structural damage to the fiberglass, such as cracks or holes. Patch repair kits are ideal for fixing larger areas of damage and typically include fiberglass cloth or mat, resin, and other necessary tools for a complete repair.

What are the different surface coatings available for fiberglass?

There are several different surface coatings available for fiberglass, including gelcoat, epoxy resin, polyurethane paint, and vinyl ester resin. Each coating offers different benefits and characteristics, such as durability, UV resistance, and chemical resistance, allowing for customization based on specific needs and preferences.

How is fiberglass supply manufactured?

Fiberglass supply is typically manufactured through a process called fiberglass fabrication, which involves several steps. Firstly, glass fibers are produced by melting raw materials such as silica, limestone, and soda ash, and then forcing the molten glass through tiny holes to form thin fibers. These fibers are then treated with a sizing agent to improve their strength and compatibility with the resin matrix.

Next, the fibers are gathered and woven into a mat or fabric, or chopped into shorter strands known as chopped strand mat (CSM). The mat or fabric can be produced in different thicknesses and weights to suit specific applications.

After the fabric or mat is ready, a resin is applied to it using various techniques such as hand lay-up, spray-up, or filament winding. The resin, which is usually a thermosetting polymer like polyester or epoxy, acts as a binding agent and provides the final structure with strength and rigidity. Once the resin has been applied, it undergoes a curing process, often through the application of heat, to harden and solidify the fiberglass composite.

Finally, the cured fiberglass supply is trimmed, cut, or shaped into the desired form, which can range from sheets, panels, or rolls to custom-molded parts. The manufactured fiberglass supply is then ready to be used in various industries such as construction, automotive, aerospace, and marine, where its excellent strength-to-weight ratio and corrosion resistance make it a popular choice.

Wholesale Fiberglass Supply from supplier in Mali

We are a Fiberglass Supply supplier serving the Mali, mainly engaged in the sale, quotation, and technical support services of various Fiberglass Supply products in the Mali region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Fiberglass Supply procurement services in the Mali. Not only do we have a wide range of Fiberglass Supply products, but after years of market development in the Mali, we can also provide valuable experience for your projects.

Hot Search

- Fiberglass Chopped Strand in Finland

- Fiberglass Mesh Cloth in Italy

- Composite Pipes in Nicaragua

- FRP Pultrusion Profiles in Fiji

- Fiberglass Mat Tissue in Iceland

- Fiberglass Fabrics in Guinea

- Fiberglass Mesh in Papua New Guinea

- Composite Tank in Netherlands

- Fiberglass Mesh tape in Malta

- Polymer in Guinea Bissau