All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

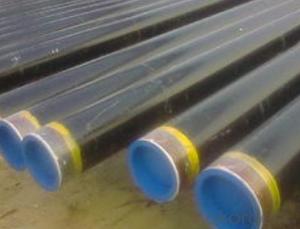

- - Seamless Steel Pipe

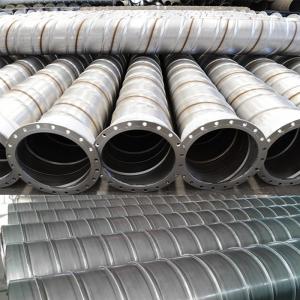

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can welded steel pipes be used for manufacturing testing facilities?

Yes, welded steel pipes can be used for manufacturing testing facilities. Welded steel pipes are known for their strength, durability, and resistance to high pressure and temperature, which makes them suitable for various industrial applications, including testing facilities. They can be used to transport different types of fluids and gases, withstand heavy loads, and maintain structural integrity, making them a reliable choice for manufacturing testing facilities.

Can welded steel pipe be used for structural supports?

Yes, welded steel pipe can be used for structural supports. Welded steel pipe is commonly used in various construction applications, including structural supports, due to its strength, durability, and ability to withstand heavy loads. It provides reliable support and is often preferred for its structural integrity and cost-effectiveness.

Are welded steel pipes suitable for structural applications?

Yes, welded steel pipes are suitable for structural applications. They offer high strength and durability, making them ideal for supporting heavy loads and withstanding various external forces. Additionally, the welding process ensures a strong and secure connection, ensuring the integrity of the structure.

What are the factors that affect the strength and durability of welded steel pipes?

There are several factors that can affect the strength and durability of welded steel pipes. Firstly, the quality of the welding process itself plays a crucial role. Proper welding techniques, including the use of appropriate heat and pressure, can ensure a strong and reliable bond between the pipes. Secondly, the choice of welding consumables, such as filler metals and fluxes, can significantly impact the strength and corrosion resistance of the weld. The composition and mechanical properties of the base metal, as well as the presence of impurities or defects, also affect the overall strength and durability of the welded steel pipes. Additionally, environmental factors such as temperature, humidity, and exposure to corrosive substances can accelerate corrosion and decrease the longevity of the pipes. Regular inspection, maintenance, and proper installation practices are essential to ensure the strength and durability of welded steel pipes in various applications.

How is the surface quality of welded steel pipe ensured?

The surface quality of welded steel pipes is ensured through various measures such as visual inspection, surface preparation, and non-destructive testing. Visual inspection involves examining the pipe's surface for any visible defects such as cracks, pits, or unevenness. Surface preparation techniques like cleaning, degreasing, and descaling are also employed to remove any contaminants or impurities that may affect the surface quality. Additionally, non-destructive testing methods like ultrasonic testing or magnetic particle inspection are utilized to detect any hidden defects or irregularities in the surface of the welded steel pipes.

Wholesale Welded Steel Pipe from supplier in Mali

We are a Welded Steel Pipe supplier serving the Mali, mainly engaged in the sale, quotation, and technical support services of various Welded Steel Pipe products in the Mali region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Welded Steel Pipe procurement services in the Mali. Not only do we have a wide range of Welded Steel Pipe products, but after years of market development in the Mali, we can also provide valuable experience for your projects.