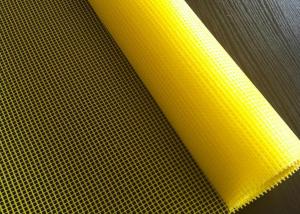

Fiberglass Mesh 75g 4*4mm

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 M2 m²

- Supply Capability:

- 10*40HQ/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Fiberglass Mesh 75g 4*4mm

Coated Alkali-resistant fiberglass mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface.

The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

The resin used for the surface treatment ensures the property of alkali-resistance and increases the mechanical durability that is required by the construction industry.

Usage/Applications of Fiberglass Mesh 75g 4*4mm

1.External Thermo Insulating Composite System (ETICS) & External Insulating Finish System (EIFS)

2.External and internal plaster reinforcement

3.Electrical heating mats

4.Marble Slab Reinforcement / Mosaic Carrier

5.Asphalt reinforcement (roof water-proof)

6.Reinforced lightweight construction boards

Packaging & Delivery of Fiberglass Mesh 75g 4*4mm

Each roll is wrapped in a shrink film or plastic bag. Then rolls are packed into cartons or pallets.

Production Line of Fiberglass Mesh 75g/m2

- Q:What is the performance of wall mesh?

- The features of wall mesh: Lightweight, high strength, heat resistance, alkali-resistant, waterproof, corrosion resistance, chap resistance and dimensional stability. Function: It can effectively avoid tension contraction of the whole surface in the plastering layer and cracks caused by an external force. Dimensions: The width has 10cm, 15cm, 20cm, 30cm and 1-meter (Friendly reminder: Please everyone to select the size of the purchase amount based on the actual situation) If the wall is in serious condition, it should be eradicated and re-done. There is no need to use mesh. The effect cement will be even better, if in the fear of cracking, you can use the cement again after the cement dries.

- Q:Are fiber glass lightweight composites?

- Glass fiber itself is an inorganic non-metallic material, glass fiber as the base material of composite materials, and resin with the formation of composite materials, alone, glass fiber is a composite material unscientific.

- Q:cracking resistant mortar and the adhesive force of the mesh

- Cracking mortar is an organic adhesion agent, the product has a high bonding strength, inorganic binding material mixed by a certain percentage, and it is usually made of a thermal insulation with galvanized steel or alkali fiberglass mesh cloth composite coating, not powder cracking, wall panels, graded sand, the product has high strength, and is cement concrete products.

- Q:How to paste reinforced mesh into the reverse side of stone?

- The professional term is back mesh. Firstly, dry the mesh, then brush glue, and pave mesh, finally wait it to become dry.

- Q:Should the wall be pasted with gridding cloth before painting?

- According to the processing, please check whether greasy layer has water resistance or powder removal. The cement mortar layer should be processed with adhesion agent which is used for solidifying. Then thick leveling materials are used for guarantying the stability of architectural surface durability by selecting wallpaper, latex paint and diatom ooze.

- Q:What is the function of epoxy resin mesh

- it is mainly used for the casting transformer and electric reactor, soaking in the epoxy resin, and the mesh of H level epoxy glass is using the alkali-free glass fiber with high insulation grade, no partly emission and no bubble in the interior. The product is impregnated throughly in the epoxy resin, solidified and sizinged by drying, and the terylene interweaving to the square opening gridding and the gray cloth is dehydrated by high temperature.

- Q:What's the difference between window screens and window screens?

- Screen window is made of chemical fiber as raw material. It's a very thin cloth. Usually with curtain cloth matching. A cloth. Ply yarn. A gauze screen that sticks over a door and window to become a window screen; a screen is widely used in doors and windows and corridors to prevent small insects from disturbing the net. Mostly made of nylon, common white, green and blue. Sometimes also called screen window. The main role is "anti mosquito screen window". Now the screen window is more than before, more patterns, invisible screen window and removable screen window, no longer as hard as before the window will be removed and removed.

- Q:How to layout alkali resistant glass fiber grid cloth?

- When seeting walls, gridding cloth can be cut along with the the dividing joint. Reason: the gridding cloth is used for crack resistance and the dividing joint can help reduce wall stress, therefore, it can be a way to reduce crack. Cutting is ok as long as the cardinal plane of base is not affected.

- Q:What are fiberglass and fiberglass?

- There are many kinds of glass fiber, and their chemical composition, production methods, morphology, properties and uses are also different, so there are different classification methods,

- Q:When the wall plastering, can use galvanized steel mesh instead of alkali glass fiber mesh cloth?

- It's too expensive. It's wasteful and bad to handle.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China |

| Year Established | 2009 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | about 300 |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | about 4000m2 |

| No. of Production Lines | 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | 0.13 usd/m2-0.28usd/m2 |

Send your message to us

Fiberglass Mesh 75g 4*4mm

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 M2 m²

- Supply Capability:

- 10*40HQ/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords