All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

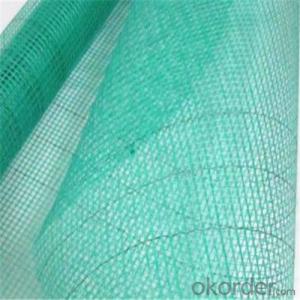

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

Can fiberglass be used for making automotive body parts?

Yes, fiberglass can be used for making automotive body parts. It is a lightweight and durable material that is commonly used in the production of various vehicle components, including body panels, hoods, fenders, and spoilers. Fiberglass offers excellent strength-to-weight ratio, corrosion resistance, and design flexibility, making it suitable for automotive applications.

How do you reinforce medical components with fiberglass materials?

To reinforce medical components with fiberglass materials, the first step is to prepare the surface of the component by cleaning it thoroughly and removing any contaminants. Then, a layer of fiberglass cloth or mat is applied to the desired area, ensuring proper coverage and alignment. The cloth is then saturated with epoxy resin, which acts as a binder and provides strength. This resin is applied evenly using a brush or roller, ensuring that all fibers are well saturated. The component is then left to cure, typically at room temperature, allowing the resin to harden and form a strong bond with the fiberglass. This reinforcement process helps enhance the structural integrity and durability of the medical component.

How is fiberglass used in the production of water tanks?

Fiberglass is commonly used in the production of water tanks due to its excellent properties. It is utilized to reinforce the tanks, providing strength and durability. The fiberglass material is typically used to create the outer shell of the tank, acting as a protective layer against corrosion and leakage. This material is lightweight, yet highly resistant to the harsh environmental conditions and chemicals commonly found in water systems. Additionally, fiberglass allows for flexibility in tank design, enabling the production of tanks in various shapes and sizes to meet specific requirements. Overall, fiberglass plays a crucial role in enhancing the performance and longevity of water tanks.

Can fiberglass supply be used for making water slides or amusement park rides?

Yes, fiberglass supply can be used for making water slides or amusement park rides.

Wholesale Fiberglass Supply from supplier in Austria

Whether you need fiberglass materials for construction, industrial applications, or any other project, we have you covered. Our sales team is knowledgeable and experienced, ensuring you receive personalized service and the right products for your specific requirements.

In addition to our sales services, we also provide quotations to help you plan and budget your projects effectively. Our team will work closely with you to understand your needs and provide competitive pricing options.

Technical support is another aspect we excel in. Our experts have a deep understanding of fiberglass materials and their applications. They are available to answer any questions you may have, provide technical guidance, and assist you in finding the best solutions for your projects.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast network of resources and expertise. This enables us to stay up-to-date with the latest industry trends and innovations, ensuring we can provide you with the most advanced and high-quality fiberglass products in the market.

At our company, we value customer satisfaction above all else. We strive to build long-lasting relationships with our clients by delivering exceptional products and services. Our aim is to become your trusted partner for all your fiberglass supply needs in Austria.

Contact us today to discuss your requirements and experience the difference of working with a leading provider of fiberglass supply products in Austria.

In addition to our sales services, we also provide quotations to help you plan and budget your projects effectively. Our team will work closely with you to understand your needs and provide competitive pricing options.

Technical support is another aspect we excel in. Our experts have a deep understanding of fiberglass materials and their applications. They are available to answer any questions you may have, provide technical guidance, and assist you in finding the best solutions for your projects.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast network of resources and expertise. This enables us to stay up-to-date with the latest industry trends and innovations, ensuring we can provide you with the most advanced and high-quality fiberglass products in the market.

At our company, we value customer satisfaction above all else. We strive to build long-lasting relationships with our clients by delivering exceptional products and services. Our aim is to become your trusted partner for all your fiberglass supply needs in Austria.

Contact us today to discuss your requirements and experience the difference of working with a leading provider of fiberglass supply products in Austria.

Hot Search

- Fiberglass Chopped Strand in Rwanda

- Fiberglass Mesh Cloth in Mongolia

- Composite Pipes in Zimbabwe

- FRP Pultrusion Profiles in Chad

- Fiberglass Mat Tissue in Liechtenstein

- Fiberglass Fabrics in Belarus

- Fiberglass Mesh in Tunisia

- Composite Tank in Haiti

- Fiberglass Mesh tape in Argentina

- Polymer in Andorra