All Categories

- - Steel Wire Rod

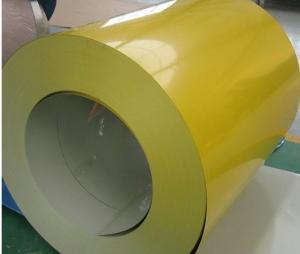

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does coil memory and shape influence the usability of steel coils in various applications?

Coil memory and shape greatly influence the usability of steel coils in various applications. The ability of a steel coil to retain its original shape after being bent or manipulated is crucial in applications where structural integrity and dimensional accuracy are required. Steel coils with good coil memory can be easily formed, shaped, and handled, ensuring a high level of usability in industries such as automotive, construction, and manufacturing. Additionally, the shape of the coil, whether it is flat, round, or custom, determines its compatibility with specific machinery and equipment. Therefore, coil memory and shape play a vital role in determining the usability and effectiveness of steel coils in various applications.

What measures are in place to ensure coil gauge consistency during the manufacturing of aerospace components?

To ensure coil gauge consistency during the manufacturing of aerospace components, several measures are in place. Firstly, strict quality control procedures are followed at every stage of the manufacturing process. This involves regular inspections and measurements of the coil gauge to ensure it meets the required specifications.

Additionally, automated systems and advanced machinery are utilized to accurately measure and control the coil gauge. These systems are capable of detecting even the slightest variations in gauge thickness and can adjust the manufacturing process accordingly to maintain consistency.

Furthermore, comprehensive training programs are provided to the manufacturing personnel to ensure they are well-versed in maintaining coil gauge consistency. They are educated on the importance of gauge control and taught how to identify and rectify any deviations from the desired specifications.

Overall, a combination of stringent quality control procedures, advanced measurement systems, and skilled workforce contributes to the effective management of coil gauge consistency in the manufacturing of aerospace components.

What is the role of tension leveling in the production of metal roofing materials?

Tension leveling plays a crucial role in the production of metal roofing materials by removing any residual stresses and ensuring uniform flatness across the metal sheets. This process allows for better formability, improved surface quality, and enhanced performance of the final roofing product.

Wholesale Steel Coils from supplier in Austria

Contact us today to discuss your Steel Coils requirements and let us provide you with the best solutions for your needs. We look forward to serving you and exceeding your expectations.