All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel pipes used in the automotive industry for fuel injection, transmission, and exhaust systems?

Steel pipes are commonly used in the automotive industry for fuel injection, transmission, and exhaust systems due to their durability, heat resistance, and ability to withstand high pressure. In fuel injection systems, steel pipes are used to transport fuel from the tank to the engine, ensuring efficient and precise fuel delivery. In transmission systems, steel pipes are utilized for hydraulic fluid transfer, aiding in smooth gear shifting and overall performance. Lastly, steel pipes are crucial in exhaust systems as they effectively channel and expel hot gases from the engine, contributing to improved emissions control and engine efficiency.

What are the challenges and solutions for inspecting and maintaining underground steel pipelines?

The challenges of inspecting and maintaining underground steel pipelines include limited accessibility, corrosion, and potential leaks or ruptures. These pipelines are often buried deep underground, making it difficult to visually inspect them regularly. Corrosion is a common issue in steel pipelines due to exposure to moisture and chemicals, which can weaken the integrity of the pipes. Additionally, leaks or ruptures can occur, leading to environmental hazards and service disruptions.

To address these challenges, various solutions can be implemented. One approach is the use of advanced inspection technologies such as inline inspection tools or robotic devices that can navigate the pipelines and provide real-time data on their condition. These technologies can detect corrosion, cracks, or other defects, allowing for timely maintenance and repairs.

Regular maintenance practices are crucial in preventing pipeline failures. This includes cathodic protection systems that help inhibit corrosion by introducing an electrical current to the pipeline, as well as applying protective coatings to prevent direct contact with corrosive elements. Implementing a proactive maintenance program with scheduled inspections, corrosion monitoring, and preventive maintenance can significantly extend the lifespan of underground steel pipelines.

Furthermore, the development and adoption of non-destructive testing methods can aid in identifying hidden defects without the need for excavation. Techniques such as electromagnetic testing, ultrasonic testing, or acoustic emission monitoring can be employed to detect and evaluate potential issues, ensuring the integrity of the pipeline.

Overall, a combination of advanced inspection technologies, regular maintenance practices, and proactive measures can help mitigate the challenges associated with inspecting and maintaining underground steel pipelines, ensuring their safe and reliable operation.

What is the significance of ultrasonic testing in detecting internal defects in steel pipes?

Ultrasonic testing is highly significant in detecting internal defects in steel pipes due to its ability to accurately and non-destructively identify flaws that may compromise the structural integrity of the pipe. By using high-frequency sound waves, ultrasonic testing can penetrate the material and produce detailed images of the internal features. This enables the detection of defects such as cracks, corrosion, and inclusions, which are not visible to the naked eye. The early detection of these flaws through ultrasonic testing allows for timely repairs or replacements, ensuring the safety and reliability of the steel pipes in various industries, including oil and gas, construction, and manufacturing.

What is the impact of corrosion inhibitors on the longevity of steel pipes?

Corrosion inhibitors have a significant impact on the longevity of steel pipes. These inhibitors work by either forming a protective layer on the surface of the steel or by altering the corrosive properties of the surrounding environment. By preventing or slowing down the corrosion process, they can extend the lifespan of steel pipes. This helps to avoid costly repairs or replacements, ensuring the long-term durability and functionality of the pipes.

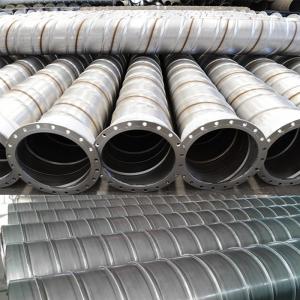

Wholesale Steel Pipes from supplier in Austria

Whether you are in need of seamless or welded steel pipes, we have a wide range of options to meet your specific requirements. Our team of experts is dedicated to providing you with the highest quality products, ensuring durability and reliability for your projects.

In addition to our extensive product range, we also offer comprehensive sales and quoting services. Our knowledgeable sales team will work closely with you to understand your project needs and provide you with competitive pricing and timely quotations. We understand the importance of budget considerations, and we strive to offer cost-effective solutions without compromising on quality.

Furthermore, our technical support services are designed to assist you throughout the entire procurement process. Our team of technical experts is available to answer any questions you may have and provide guidance on product selection, installation, and maintenance. We believe in building long-term relationships with our customers, and we are committed to providing you with ongoing support and assistance.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to ensure a seamless procurement experience for our customers in Austria. CNBM is a trusted and renowned name in the steel industry, known for its expertise, reliability, and commitment to customer satisfaction. By choosing us as your supplier, you can be confident in the quality and reliability of our products and services.

Contact us today to discuss your steel pipe requirements in Austria. We look forward to partnering with you and providing you with the best solutions for your projects.

In addition to our extensive product range, we also offer comprehensive sales and quoting services. Our knowledgeable sales team will work closely with you to understand your project needs and provide you with competitive pricing and timely quotations. We understand the importance of budget considerations, and we strive to offer cost-effective solutions without compromising on quality.

Furthermore, our technical support services are designed to assist you throughout the entire procurement process. Our team of technical experts is available to answer any questions you may have and provide guidance on product selection, installation, and maintenance. We believe in building long-term relationships with our customers, and we are committed to providing you with ongoing support and assistance.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to ensure a seamless procurement experience for our customers in Austria. CNBM is a trusted and renowned name in the steel industry, known for its expertise, reliability, and commitment to customer satisfaction. By choosing us as your supplier, you can be confident in the quality and reliability of our products and services.

Contact us today to discuss your steel pipe requirements in Austria. We look forward to partnering with you and providing you with the best solutions for your projects.