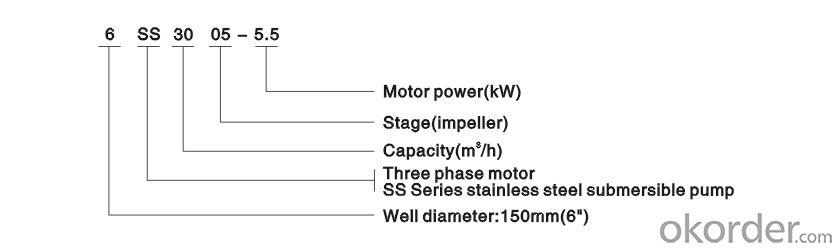

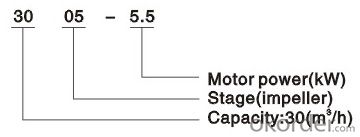

Well Pump 6SS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

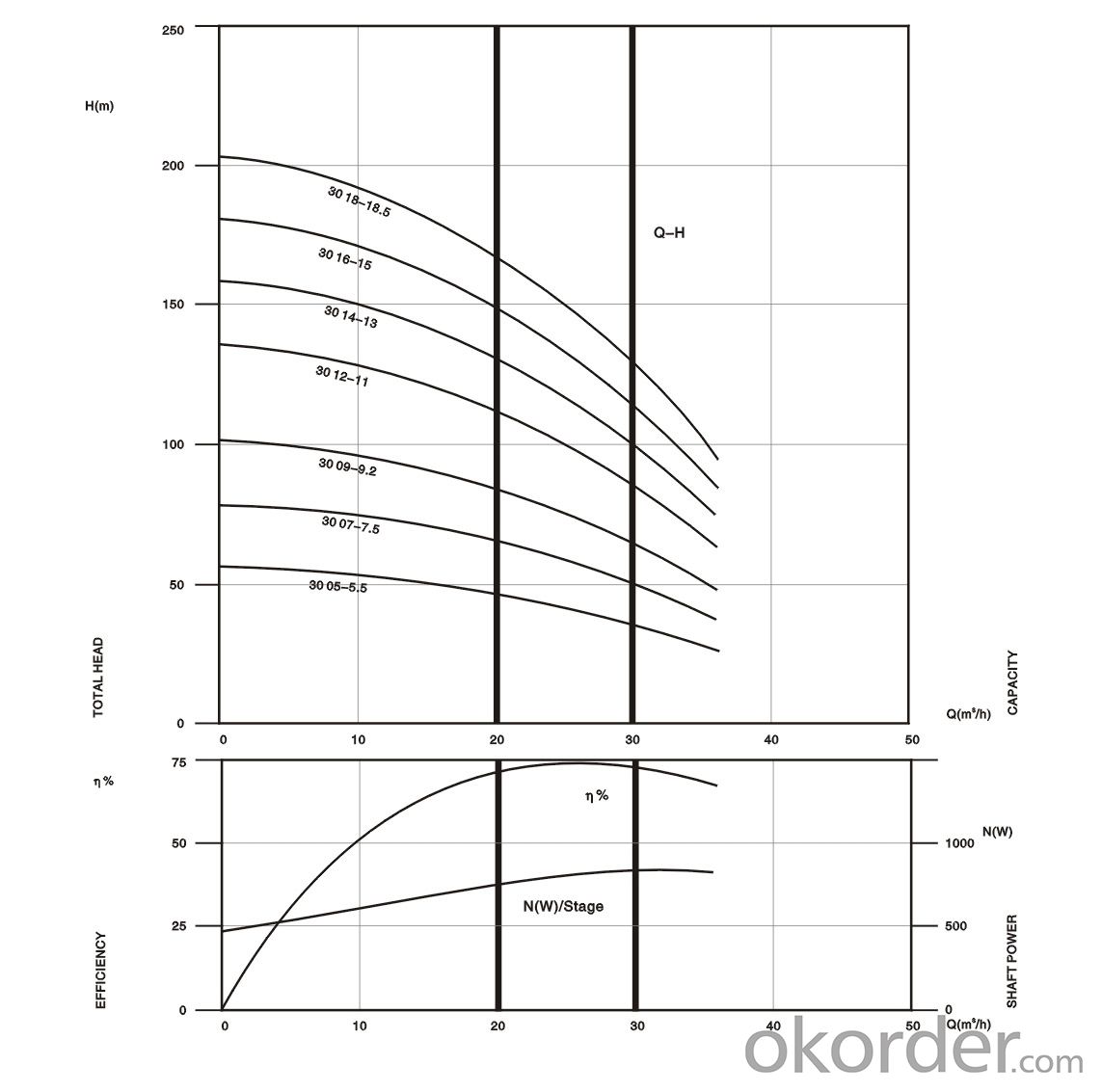

Well Dia.:150mm(6") -Typical applications -Working conditions -Pump/Motor |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: What is the function of boiler feed pump, condensate pump, vacuum pump and low drain pump in operation?

- The feed pump is a pump for supplying water to the boiler and maintaining the water level of the boiler. The condensate pump provides water to the deaerator after condensing the turbine and provides water for some condensate users. Vacuum pump is to maintain the vacuum of the pump, the pump is to lower the drain in a timely manner to the next level of low pump

- Q: there is a knocking noise coming from the water pump pulley..i think, the pulley also wiggles when its running. If that's what is wrong, how long do i have to fix it and is it hard and expensive to fix?

- No it isn't hard to fix, first loosen the little bolts on the water pump pulley, then take the belt off, then unbolt the water pump and take pulley off old pump, clean off old seal from block, put on new seal, you may have to use gasket maker or silicone, install new pump, and bolt pulley on to new pump, then reinstall belt. Oh I forgot you will have to drain the antifreeze before you start, and refill it after you are done! Start the car and let it warm up and look for leaks, if you see a leak you didn't get it sealed properly and will have to repeat the sealing process and antifreeze. Takes an hour or so to do!

- Q: Having a hard time taking out the water pump on my 2004 Grand Am. it's been leaking anti-freeze for some time and finally had the time to fix it. Didn't know it will be so difficult to take out. So hopefully it won't be so difficult to put back up.

- You did not say if you have a 4 cylinder or a 6 cylinder. The 6 is really easy so I will assume you have a 4.If equipped with an automatic transmission, remove the exhaust manifold. Refer to Exhaust Manifold Removal in Engine Mechanical - 2.2L (L61). Drain the cooling system. Refer to Cooling System Draining and Filling . Raise and suitably support the vehicle. Refer to Lifting and Jacking the Vehicle in General Information. Remove the right front tire and wheel. Refer to Tire and Wheel Removal and Installation in Tires and Wheels. Remove the front fender liner. Refer to Front Fender Liner Replacement in Body Front End. Remove the access plate on the water pump sprocket from the timing cover. Install J 43651 to the water pump sprocket. Use the access plate bolts to secure J 43651 to the engine front cover. Remove the bolts that secure the sprocket to the water pump. Remove the bolt (1) that secures the engine block to the water pump. Remove the bolt (2) that secures the engine front cover to the water pump. Remove the feed pipe that joins the thermostat housing to the water pump. Remove the 2 bolts that secure the water pump to the engine block. Remove the water pump.

- Q: 2 inches of water pump is generally equipped with high-power motors

- Clean water pump 5.5 kw

- Q: Where is the water pump located on a 1993 mitsubishi eclipse with a 1.8 motor

- Your water pump would be located on the right hand side of the motor. It has the fan belt running on the pulley in front of it the top water hose is connected to it. I hope this has helped you out.

- Q: Variable flow variable frequency water pump how to adjust the flow?

- Variable frequency pump is mainly depending on the frequency converter to adjust the speed of the pump motor, thereby regulating the flow and lift pump, the following Q1/Q2=n1/n2; H1/H2= (n1/n2) -, the frequency range of the frequency converter in 30HZ~50HZ

- Q: water pump on a Suzuki forenzakia optima

- You better shop around on that one but you're looking at a few hundred dollars minimum. The newer the car, the more you're going to pay to get it fixed.

- Q: Motor has over 200k miles. Water pump took a dump. Gear is very wobbly! primary timing chain tensioner off the right bank hasn't any tension on chain at all! Crank turns but doesn't turn the chain. So motor is way out of time for sure now.Found small piece of aluminum and 2 -1/2pieces of appears to be a spring pin. Am I correct to assume these pieces are from the water pump? A new chain and water pump I can see doing on this old motor! But? Any suggestions on what to do next before I waste my money? What kind of compression reading can I get with all the plugs out and manually turning the crank? Short answers of scrap it not welcomed! I'll determine that after I'm satisfied it's truly bad! Thanks!

- I also own a 2001 Intrepid and recently had a water pump go bad which also broke my timing chain. The pieces of aluminum you found are probably valves or valve springs from the head. Mine broke every vavle and spring on one head when my engine jumped time and a few more on the other head that is probably what your seeing. Also you don't want to check for compression by turning the crank manually. It is an expensive job to fix but the cars are great but I wouldn't spend too much on them because they only go for about $3000-3700 in great condition nowadays. Good Luck

- Q: Work done in water pumping?Water is to be brought from a well 60 meters bellow ground level to a tower 10 meters high, once there the water falls freely on a 5000 liter tank. A submerged pump 10 meters under water level and a two inch diameter pipe is to be used. What is the work done by the pump when 2000 liters have been served to the tank; what is the power of a pump selected to do this work in 20 minutes.

- Power_W = (Mass_kg * Gravity_m/s/s * Height_m) / time_s Where: Mass kg is 1kg/l of 2000 liters Gravity is 9.81m/s/s Head is 60m + 10m (height). The suction head is ignored because the pump is submerged. In practice there is some suction head due to intake restrictions like pipes, check valves, strainers. The time is 20 minutes in seconds. The work is the energy used in the time allocated, which is: power * time in seconds, which is watt seconds = joules. Not needed here as it is in the formula above. Power is the rate of doing work. The depth below water is not really relevant except for pipe losses which increase the head slightly. The flow is 2000 liters/20 minutes = 100 l/min. This can be used with the head of 70m to determine the pipe restriction, which amounts to a pressure drop representing extra head added. It will indicate whether the pipe is too small (excessive head added) or whether the pipe is overkill (no head added). You can find on line calculators for this, e.g. search pipe resistance flow on line calculator. I am guessing a 2 inch pipe has little loss at this flow. This is the so called water power. It is the output power of the pump. The pump may only be 50% or so efficient, so the mechanical power delivered by the motor needs to be greater by this ratio. The electrical input power to the motor is greater again to allow for motor efficiency. This might be 60-90%. In practice the efficiency of pump and motor are determined from user manual or specification of the actual devices with the actual loads (head and flow).

- Q: 89 Dodge van overheats, no water leak, replaced thermostat but still overheats.

- leave the cap off and start it. if it circulates then the water pump is still good. you say it overheats? flush out the radiator. if that van has a electric fan then make sure it is kicking on.

Send your message to us

Well Pump 6SS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords