Single Stage Double Suction Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

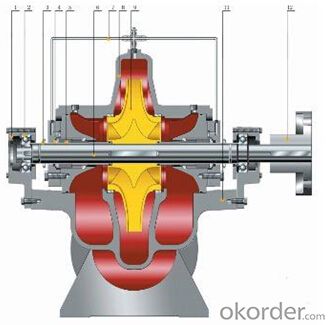

Single Stage Double Suction Centrifugal Water Pump for Irrigation

1.Structure of Single Stage Double Suction Split Casing Water Pump Description

The Single Stage Double Suction Water Pump is designed for Irrigation, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of the Single Stage Double Suction Water Pump

• Compact structure

• Attractive design

• High efficiency, steady performance

• big capacity, medium pressure

• High concentricity of components

3. Single Stage Double Suction Water Pump Images

4. Single Stage Double Suction Water Pump Specification

Specification Parameter of Single Stage Double Suction Split Casing Centrifugal Pump

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

5.FAQ

①What is the applications?

Besides irrigation and drainage pumping Station, the Single Stage Double Suction Split Casing Centrifugal Pump also can be used for Circulation water for air-condition, water supply for industry and building, and other waterworks.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. It related to the state and detailed requirement of customers.

- Q: what is NPSH for the water pump. Can you anyone explain in details? How can it calculate?

- NPSH stands for Net Positive Suction Head. It usually refers to the amount of pressure needed at the inlet of the pump for the pump to work properly. If there is insufficient pressure pushing the fluid into the pump, and the pressure at the inlet is lower than the NPSH requirement, then the pressure will be so low in the sucking center of the pump that the fluid will boil (this is called cavitation). It usually makes a racket, reduces pump performance, and erodes away the pump. To make sure this doesn't happen you have to have enough head (as in some level in the tank feeding the pump) and low pressure drop on the way to the pump (meaning big enough lines, no obstructions, and not too many bends). Some pumps are designed for very low npsh requirements. These pumps can suck water from some depth without cavitating. No pump can suck room temperature water from fore than about 25 feet below the pump, because the vacuum needed to lift the water 25 feet or so is close to the vacuum needed to boil water at room temperature. You cannot easily calculate the npsh a pump needs. This is a function of the design and geometry of the pump. You can calculate the delivered npsh by figuring the pressure of the liquid in the feed tank (don't forget atmospheric pressure) and subtracting the pressure loss due to friction in the piping between feed tank and pump. This loss will be a function of flow rate. Faster flow, more frictional pressure loss.

- Q: What are the quota items for the complete pump installation?

- It can be divided into the following sections:1. pump installation platform, to obtain concrete and reinforced section (if any)2. anchor bolt installation: cap construction reserved bolt mounting holes of the anchor bolt installation hole grouting taking, (may be incorporated into the 1), and the damping piece related item;3. pump installation: installed in the installation of fixed item taking pump, check the wiring and debugging section, the first cable.The above is only a rough expression, the specific problems are flexible.If you still don't understand, you can contact me.

- Q: NEED WATER PUMP AND HOSES, AND A PRICE QUOTE...

- That van will have either the 3.3L or 3.8L engine. Both use the same water pump. It should run you somewhere in the $35.00 range for the pump. The hoses will depend on the brand you chose, but you should be able to get both the upper and lower radiator hose, and the pump, for under $100. Any parts store should either have these in stock or should be able to get them for you within a few hours! This does not include labor. If you are going to do the pump replacement yourself, you will need to be very careful when you remove the bolts that hold the pump. They are thin, and have a tendency to break. You have to be very gentle to avoid breaking off a bolt, or you will have to drill the bolt out. There is not a lot of clearance, so it is difficult to drill. When you replace the water pump, check the serpentine belt for cracks. It is easier to replace it while it is loose than to have to do it later.

- Q: I have a 2000 Ford Focus with 82k miles on it. The car is leaking coolant intermittently. The radiator was replaced about 3 yrs ago. The car doesn't overheat but when I turn it off I can hear a boiling sound and it smells like something is burning. It's not a strong smell but it's there. The car also idles rough and downright shakes at times. Also, and I know this sounds crazy, when I'm driving it I hear a sort of whooshing noise that sounds like water. Could this be the water pump or something more serious? I'm taking it to the mechanic tomorrow but would like an idea as to what could be wrong.

- Could be thermostat, or a head gasket.

- Q: Recently my car overheated on my way to work, and so I decided to give it some much needed TLC.I have replaced all in the last week:Spark PlugsDistributor Cap + RotorTiming BeltRelated to the cooling system:Water PumpThermostatAnd the heater still blows hot air so I believe the heater core is fine. Unfortunately even after a couple of radiator flushes the car continues to overheat. I'm considering replacing the radiator because I think it might have too much debris inside to flow properly.I used ZEREX Radiator Super Cleaner but was only able to acheive an hour and a half of driving before my car would not be able to drive anymore. (Supposed to be 3 hours, car temperature began to escalate far beyond what I'm confortable with) I also used ZEREX Radiator Super Flush to no avail.Any suggestions?Car info:Toyota Camry DX 19913S-FE Engine 2.0L I4 1998cc244,500 miles

- Cooling systems are simple. There are only a few things you need to know to work a cooling system. 1 – Cooling systems consist of only a few parts. Thermostat, radiator, fan, and water pump. 2 – is it visually leaking? if yes fix leak. 3 – It is never the thermostat but it is a couple bucks so change it. 4 – is the water pump pumping. This is usually not the issue and the last thing to replace. Not to mention it is the most difficult to get to so do it last. 5 – is the fan working? 6 – Usually it is the radiator itself. The radiator is pressurized and if there is a pin hole leak your car will slowly overheat. It usually takes an hour or so of driving. Also many people like stop leak and use it as a solution when it is really a band aid. Many times people will find that they have reduced water flow because the previous owner used stop leak in the radiator. Take the radiator out and take it to a radiator shop. Have them pressure test it and inspect it. Your problem is likely in the radiator.

- Q: 1998 BMW 328i : to replace water pump, thermostat and gaskets, brake flush, fuel system cleaning with tune up,drive belt for 90k serivce; totally how much bucks?thx a lot !

- At okorder to prevent mechanics from trying to rip you on the parts.... and they might not be trying to... but their prices are higher than bav's. PS... the 90K mile service is A LOT... I have never paid anyone to do it. Look in the back of your owners manual, it tells you everything they check. I check it all myself. If you change your own oil scope things out while your under the car. It's easy to spot stuff that is wearing out. You can reset the service light yourself too. :P If you don't know anything about cars however.... don't try doing it yourself.... in other words... if you are scared of doing it, don't... if you feel confident... go for it. Also... the first time you do things it might take an hour... second time will take 30 mins... 3rd time you do something it will take 10-15 mins. Most of the projects I have done have been like that. From rebuilding the internal door mechanisms to working on the engine... that's how it's been for me. Key is to not let yourself get frustrated.

- Q: Because the water pressure is too small, this summer with self suction pump 750W, water is big, but every time that water is used for the first time out of the water is yellow like rust, probably after the release of 10 liters will become clear, then is not, but every one hour after the water time out is rusty hair yellow, so to waste a lot of water, but accidentally brought cooked food should not be good to the body.Now come in the water is through the pump, even without electricity, partition time for the first time water will be yellow, there is no master can teach me to disassemble, which can be cleaned?. Or something else. Thank you

- The reason for the yellow water in the water suction pump is that the steel pipe in the underground is corroded. The water flows out through the water during the pumping process, and yellow is mainly the color of rust.Processing method: pull out the steel pipe deep into the ground and replace it with plastic pipe.

- Q: I put the new water pump in and the metal tube that goes to the heater hose it is hitting the wheel that holds the 3 belts that goes onto the water pump. why is it doing that. got the right pump. I have a 1986 firebird V6. any ideas?

- it quite is not any longer trouble-free to respond to given the coaching given. what form of motor vehicle ? in the experience that your vehicle has a waterpump this is grew to become by the timing belt, particular the save might have tousled on the cam timing as they re-assembled after setting up the pump. what's inflicting the click sound ? this is an inclination belt or any of one hundred issues. the place do you hear the sound coming from ?

- Q: I don't want to have to rent or purchase a electric pump to pump the water out of my pool so are there other ways to get the water out besides the obvious (a bucket and alot of people). I am really tight on money so purchasing a device to do the work isn't a real option but I really need to drain the pool without damaging it.

- A garden hose will do it. Just make sure that the hose runs down hill at some point to siphon the water out. Make sure that one end is in the pool and one end is at a lower spot, street,yard ,drain wherever. Then suck on that end like a straw. It will work if you got the suction. Once the water starts to drain, it will continue draining until the pool is empty..Make sure your hose is long enough to reach the bottom of the pool once you get the siphoning to start. Also make sure the water has somewhere to go..A pool holds alot of water and could flood someones yard our house easily.

- Q: The dry season river dock company from the wharf area maximum height difference of 17 meters, is the need to purchase pumps for wharf surface wash pump water, the pipeline outlet pressure to the ordinary fire water pump pressure standard, the best do not directly into the water, can be placed in the dock or wharf surface from 10 meters (below three terminal position floor, 6 meters on average one floor), to facilitate the maintenance of. What type of water pump is the best choice? What brand is the best choice at home and abroad?! Be deeply grateful!

- Domestic I do not understand, only know that you dock water, it is best to use sea water pump, or allow manufacturers to do your anti-corrosionVille, Grundfos.Lift up, I'll do it. 30m is pretty muchThe self-priming pump is OKWhich brand do you want to use? Just call them directlyLet them count it for you and then type itFirst know about yourself, generally know a power head water quantity on the line

Send your message to us

Single Stage Double Suction Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords