Horizontal Split Case Stain Steel Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

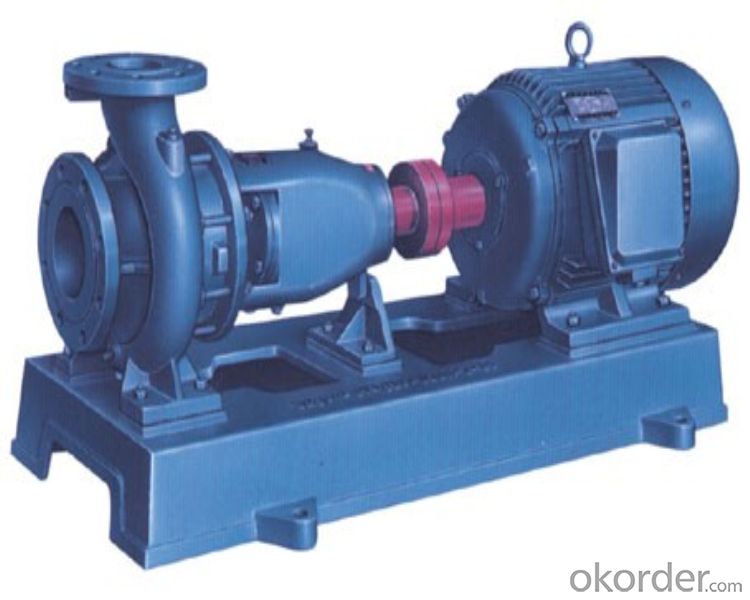

Horizontal Split Case Stain Steel Centrifugal Pump

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product Parameters of Horizontal Split Case Stain Steel Centrifugal Pump

| Capacity: | 6.3~400m³/h |

| Head: | 5~125m |

| Speed: | 2900r/min and 1450r/min |

| Power of fitted motor: | 0.55~90kW |

| Inler diameter: | 50~200mm |

| The max working pressure: | 1.6MPa |

Application Range of Horizontal Split Case Stain Steel Centrifugal Pump

1.Suitable for environment protection, construction, fire fighting, chemical pharmacy, printing, dyeing, brewage, power plant, electroplate,

paper making, washing for mining and cooling for equipment.

2.Application as sprayer equipped with beam nozzle that turning water into little drop irrigation for farm, garden, etc.

3.It is suitable for clear water, sea water, acid or alkali chemical medium and slurry (viscosity≤100 centipoise, consistency of solid can not exceed 30% of total medium).

Horizontal Split Case Stain Steel Centrifugal Pump Features

1. Resistant to acid, alkali, wear and high temperature.

2. High mechanical strength, steady performance, good tightness.

3. Convenient operation and durable.

4. Be able to transport water that under the position it was installed. No need for filling liquid after the first time it was used.

Horizontal Split Case Stain Steel Centrifugal Pump Superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

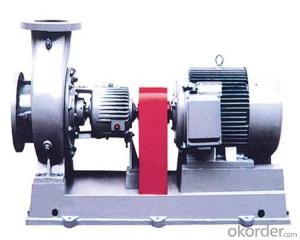

Pictures show

Why choose us

High Quality

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

After-sales service

Transportation

Related products

|

|

Fire Pump Cast Steel High Speed China Made | Cast Steel Centrifugal Pump High Pressure |

| http://www.okorder.com/p/fire-pump-cast-steel-high-speed-china-made_976663.html | http://www.okorder.com/p/cast-steel-centrifugal-pump-high-pressure_975173.html |

- Q: How much would it cost if I took it somewhere like midas?

- what variety of noise? additionally, what do you mean by skill of is it solid? They valuable looking autos IMO and that they are able to be solid if dealt with. do no longer assume to make diverse ability from the 420A engine although.

- Q: Okay so earlier, I went to go test out my water pump and all on my 66 mustang 302. And I got it up to normal operating temp, and had the rad cap off. I gave it some gas, the coolant level didn't go down, instead it came out the rad pretty badly. I've been having overheating problems, and I have no leaks, i just replaced the thermostat a few days ago, it didn't help. I haven't seen any leaks around the weep hole on the water pump, or noises. Other than a belt that does need to be tightened a bit, you can hear the belt squeling a tiny bit. So do yall think it could be my water pump?

- there are several problems that can cause this one is a stoped up radiator or a lower radiator hose thats soft

- Q: I recently took my 2002 Pontiac Grand Prix in for an oil change, and was told that my water pump has burst. I knew something happened the previous night because all of a sudden my car was overheating and when I opened the hood there was water everywhere, Anyways I am currently a single mom, working temp jobs while I look for something permanent. I can not afford the 350.00 to get it fixed. If I continue to drive the car am I looking at serious damage, He showed me how to fill the water tank (or whatever) so that the car will not be empty, But he says I need to get it fixed soon

- This Site Might Help You. RE: How serious is a broken water pump on a car? I recently took my 2002 Pontiac Grand Prix in for an oil change, and was told that my water pump has burst. I knew something happened the previous night because all of a sudden my car was overheating and when I opened the hood there was water everywhere, Anyways I am currently a single mom, working...

- Q: How do I know the pump pressure?

- Flow 18 cubic meters / hour, lift 100 meters, power 4 kilowatts.The pressure supplied by the pump is 1.0Mpa, which is 10 kg pressure.Is it a multistage pump?

- Q: How do I replace the water pump on a 1996 Mercury 200 hp outboard engine? I have the parts, but want to make sure I replace it correctly. Thanks!

- I strongly suggest that you purchase the Bible at a local outboard shop, it has exploded views and good directions, as well as tips, even if you don't know a lot about engine's it will educate you about YOUR engine, just thumb through it, the water pump change out directions are very good !

- Q: I found a small submersible water pump for pond decorations or birdbaths in my garage. It's about the size of three decks of cards stacked on top of each other. Would there be any harm/benefit of putting this into a 55 gal fw community tank?

- well it depends, do you have any small fish? and how is the water cycled in the pump? it needs to be protected so that fish dnt obviously get sucked. before you add it in tho need it submerged in a bucket of water and add several teaspoons of salt; that will kill all the bacteria that may have grown on and inside the pump. leave it in there for minimum 24 hours (just to be sure).

- Q: i mean, the water that runs through the ground from rain and ends up in the pit in the basement,is it clean to drink in an emergency? live close to a public road where they salt for snow and ice, so do you suppose that is in the water?

- yes, I would bet it is in the water. sump pump water is consider by the industry to be GRAY water. you don't want to drink it. if its an emergency, you could boil it, but not in w.v. if you are living there with this type of spill they incurred. even boiling that water will not work. better safe than sorry

- Q: Why should the pump fill the air before running? What's the reason why the water doesn't go up?

- First of all, why should exhaust air, pump suction principle is the rotation of the impeller, pump water inside the throw out, and then let the inlet pipe into a vacuum. Then, under the influence of atmospheric pressure, the water pressure is pumped into the pump. Therefore, if the water is not filled, the sealing of the pump is impossible to pump the air inside the evacuation of high vacuum. In other words, do not fill the water, you can not smoke water. You can hear the noise in the pump when the water bubbles under the bottom vacuumThe water doesn't go up because it doesn't have enough vacuum!The reason 1 is because there is no water filling,2, because your pump and water vertical height higher than the pump itself suction stroke.3., the pipeline resistance is too large (including the pipe diameter is too small, elbow and so on)

- Q: toyota prius 2002 inverter water pump where is located and how to replace and buy

- Go okorder /

- Q: Is this a symptom of a bigger problem or do I just need to replace the water pump?

- either the water pump gasket is leaking, or the water pump impeller seal is leaking. bith can be fixed by replacing the water pump. after replacement make sure to check for any other leaks.

Send your message to us

Horizontal Split Case Stain Steel Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords