GC378LC-8 Hydraulic Crawler Excavator

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 40 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GC378LC-8 Hydraulic Crawler Excavator’s Operating Weight is 35.7t, equipped with CUMMINS 6C8.3 Engine, with Boom 6.47m, Arm 3.186m, Bucket 1.62m3.

GC378LC-8 Hydraulic Crawler Excavator

Technical Specifications

Engine | Travel System | ||||||||||||

Model | CUMMINS 6C8.3 | Travel motors | BONFIGLIOLI, Italia; /NABTESCO, Japan; Variable axial piston motor | ||||||||||

Type | Water cooling, turbocharged, empty enter-cooling | Support roller quantities | 2×9 | ||||||||||

Carrier roller quantities | 2×2 | ||||||||||||

No. of cylinder | 6 | Travel shoes | 2×48 | ||||||||||

Bore and stroke | 114mm×134.9mm | Travel speed | 5.0/3.0km/h | ||||||||||

Displacement | 8.29L | Drawbar pulling force | 280kN | ||||||||||

Power output | 186kW/2200rpm | Grade ability | 70% (35°) | ||||||||||

Ground clearance | 565mm | ||||||||||||

Hydraulic System | Cab & Control | ||||||||||||

Pump | LINDE, Germany | Cab | All-weather, sound-suppressed Cab and equipped with a heavy, insulated Floor Mat; Front Window can be opened and slid; 6-direction adjustable Seat; LED display, Automatic monitoring, display and warning; cool & hot Air Conditioner | ||||||||||

Type | variable double–piston pump | ||||||||||||

Max. discharge flow | 670.6L/min | ||||||||||||

Max. discharge pressure | |||||||||||||

Boom, arm and bucket | 32.3MPa | Control | Two hand levers and two foot pedals for travel Two hand levers for excavating and swing; Electric rotary-type engine throttle | ||||||||||

Travel circuit | 32.3MPa | ||||||||||||

Swing circuit | 28MPa | ||||||||||||

Control circuit | 3.8MPa | Boom, Arm & Bucket | |||||||||||

Pilot control pump | Gear type | Boom cylinder | 140mm×100mm×1480mm | ||||||||||

Main control valve | Negative flow control | Arm cylinder | 160mm×110mm×1825mm | ||||||||||

Oil cooler | Air cooled type | Bucket cylinder | 150mm×105mm×1250mm | ||||||||||

Swing System | Refilling Capacities&lubrications | ||||||||||||

Swing motor | SUNJIN, Korea | Fuel tank | 580L | ||||||||||

Swing motor type | Axial-piston motor | Cooling system | 24.7L | ||||||||||

Brake | Hydraulic oil released | Engine oil | 28L | ||||||||||

Parking brake | Hydraulic disc brake | Hydraulic oil tank | 380L Tank oil level | ||||||||||

Swing speed | 9.7r/min | 450L Hydraulic system | |||||||||||

Bucket | |||||||||||||

Type | Backhoe bucket | ||||||||||||

Bucket capacity | 1.62m3 (SAE) | ||||||||||||

Bucket width | 1571mm | ||||||||||||

Arm Type |

| ||||||||||||

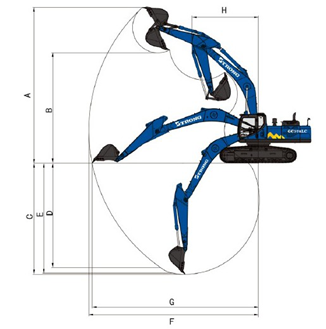

A | Max. digging depth | 10134mm | |||||||||||

B | Max. dumping height | 7182mm | |||||||||||

C | Max. digging height | 7240mm | |||||||||||

D | Max. vertical digging depth | 7170.5mm | |||||||||||

E | Max. Depth cut for 2440m(8')Level Bottom | 6812.5mm | |||||||||||

F | Max. digging distance | 11051mm | |||||||||||

G | Max. digging radius at ground level | 10839mm | |||||||||||

H | Min. swing radius of work equipment | 4332mm | |||||||||||

Digging Force (ISO6015) Unit: kN | |||||||||||||

Arm length | 3200mm | ||||||||||||

Bucket digging force | 213kN | ||||||||||||

Arm digging force | 150kN | ||||||||||||

Arm Type 3200mm | |||||||||||||

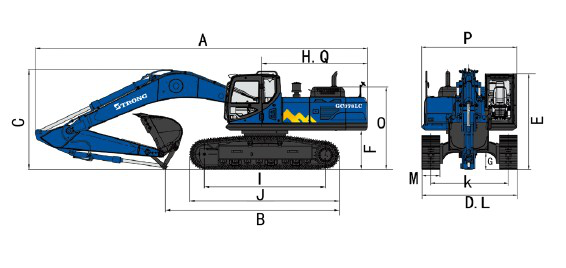

A | Overall length | 11161mm | I | Tread | 4080mm | ||||||||

B | Ground contact length (Transportation) | 5872mm | J | Track length | 5044mm | ||||||||

C | Overall height(to top of boom) | 3347mm | K | Track gauge | 2600mm | ||||||||

D | Overall width | 3200mm | L | Track width | 3200mm | ||||||||

E | Overall height(to top of cab) | 3293mm | M | Shoe width | 600mm | ||||||||

F | Counter weight ground clearance | 1312mm | O | Bonnet height | 2421mm | ||||||||

G | Ground clearance | 565mm | P | Revolving frame width | 3195.3mm | ||||||||

H | Tail swing radius | 3438mm | Q | Distance from swivel center to tail | 3438mm | ||||||||

| |||||||||||||

Operating Weight and Ground Pressure | |||||||||||||

Operating weight includes basic machine (with boom 6.47m, arm 3.186m, and bucket 1.62m3) | |||||||||||||

Shoe width | 600mm | ||||||||||||

Overall width | 3200mm | ||||||||||||

Ground pressure | 62KPa | ||||||||||||

Operating weight | 35700kg | ||||||||||||

- Q: how would you rate the quality of these mechines?

- You probably aren't going to get any serious answers in Polls and Surveys.

- Q: A company that buys excavators from an subcontractor knows by experience that certain proportion of the excavators will be faulty. 3 types of errors occurs,denoting by errortype a,b and c. Probability that errortype a occurs on a random selected excavator is 6%. For b it is 2% and for c 5%. The errors occurs independently of each other. a) Calculate the probability that a randomly chosen excavator has atleast 1 of the 3 errors b) Assume that one excavatoris shown to have both error a and b. What is probability that it also have error c ? Ans: a)0.875 b)5.0

- P(a) = 0.06 => P(not a) = 1 - P(a) = 0.94 P(b I not a) = 0.94*0.02 = 0.0188 => P(not(b I not a)) = 1 - P(b I not a) = 0.9812 P(c I not(b I not a)) = 0.9812*0.05 = 0.04906 Now the probability that a randomly chosen excavator has atleast 1 of the 3 errors P(a) + P(b I not a) + P(c I not(b I not a)) = 0.06 + 0.0188 + 0.04906 = 0.12786 And the probability that a randomly chosen excavator has no error is 1 - 0.12786 = 0.87214 b) this is obvious: 0.05 since c error is independent.

- Q: VOLVO EC460 excavator undercarriage

- There okorder

- Q: I have read several different idea in which none worked. Your hekp would be appreciated.

- Sand is the thing. get a load delivered. It's easy to move and level with a rake or shovel.

- Q: What is the difference between a backhoe and a backhoe?

- According to the difference between the excavation route and the transportation vehicle, there are two ways to dig and unload the soil: forward excavation, lateral unloading, forward excavation and reverse dumpingAs compared with other forms of shoveling:(1): digging backhoe is characterized by "back down, forced soil cutting, the mining power shovel can stop a small, excavation to three below the soil surface, suitable for the foundation pit, foundation ditch, trench excavation depth is less than 4m, but also for soil excavation, wet soil with higher water content and to the underground water level and groundwater level in higher soil. There are two ways to operate the backhoe, namely, ditch end excavation and side ditch excavation.(2) pull shovel: digging features is "back down, self weight cut soil", and its excavation radius and excavation depth is larger, can dig the soil below the stop surface, it is suitable for digging large and deep foundation pit or underwater excavation.(3): grab digging is characterized by "straight up and down, cut the weight of soil, suitable for narrow and deep excavation pit mud or water, especially suitable for cutting under water, the soil is hard not grab construction.

- Q: Regarding fuel efficiency, performance on site, low maintenance, availability of replacement parts, etc.

- That is an impossible question to answer. It would depend too much on where you were, what you were doing and how heavily you weighted each of the criteria. But then that's true for just about any what's the best... type of question. There may be a best choice for one person in one particular situation but it is very rare that there is a clear best choice for all situations.

- Q: what is the price of a 450 hitachi excavator?

- Try okorder /

- Q: Using the “straight line method” and “Inland Revenue” approved method of depreciation calculate the depreciation for a new excavator valued at ?65,000 with a working life of 10 years and explain the residual values.

- Is there a salvage value at the end of the excavator's working life? I have no idea about the Inland Revenue approved method, sorry. You should think equal division when the term straight line method comes up in depreciation terms. You just divide the initial value over the number of working life years and that will give you the depreciation per year. In this case, the excavator depreciates at ?6,500 per year.

- Q: I am going to start selling the following: Diesel TrucksConventional TrucksBobtailsBoom TrucksCaboversCity TractorsDumpsHighway StripersCranesRoll-offsRoll-BacksEquipment HaulersEnd DumpsFlatbedsEquipment Bottom DumpsReefersLive/Walking FloorsRoll-Off TrailersRV TrailersExcavatorsYard GoatsDozersCranesBoomsManliftsBackhoes/ LoadersWheel LoadersSkidsteers (bobcats)Track LoadersMowersTool CarriersSweepersI need some suggestions on a catchy name...

- auto wiz the car place get a quick deal on my chasis

- Q: I have a 2006 Ram 3500 dually, and I'm currently running the 5.9L 610 Cummins Diesel with a 48RE 4 speed automatic. I have a bully dog programmer, set on the lowest power level, an AFE stage 2 intake, ATS arc flow intake, and a 5 inch MBRP cat back exhaust. I'm now pretty much done upgrading the engine and I'm looking for some fairly easy upgrades to help my tranny handle this kind of power. Does anyone have any suggestions? I really don't pull all that much with the truck, mainly just using it on road tooling around town and going on an occasional road trip. Once in a while I'll tow around a skid loader or a mini-excavator on a gooseneck... Any suggestions other than use a quot;light footquot; will help, Thanks

- I'm not sure if a shift kit would really be needed with an electronically controlled transmission, but it's still a good idea. Maybe a larger transmission cooler would help.

Send your message to us

GC378LC-8 Hydraulic Crawler Excavator

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 40 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords