GC228LC-8 Hydraulic Crawler Excavator

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 40 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GC228LC-8 Hydraulic Crawler Excavator’s Operating Weight is 21.7t, equipped with CUMMINS 6BTAA5.9-C150 Engine, with Boom 5.7m, Arm 2.925m, Bucket 1.0m3.

GC228LC-8 Hydraulic Crawler Excavator

Technical Specifications

Engine | Travel System | |||||||||||||

Model | CUMMINS 6BTAA5.9-C150 | Travel motors | DOOSAN, Korea; Variable axial piston motor | |||||||||||

Type | Water cooling, turbocharged, empty enter-cooling | Support roller quantities | 2×9 | |||||||||||

Carrier roller quantities | 2×2 | |||||||||||||

No. of cylinder | 6 | Travel shoes | 2×49 | |||||||||||

Bore and stroke | 102mm×120mm | Travel speed | 3.4/5.4 km/h | |||||||||||

Displacement | 5.9L | Drawbar pulling force | 178kN | |||||||||||

Power output | 112kW/1950rpm | Grade ability | 70% (35°) | |||||||||||

Ground clearance | 440mm | |||||||||||||

Hydraulic System | Cab & Control | |||||||||||||

Pump | KAWASAKI, Japan | Cab | All-weather, sound-suppressed Cab and equipped with a heavy, insulated Floor Mat; Front Window can be opened and slid; 6-direction adjustable Seat; LED display, Automatic monitoring, display and warning; cool & hot Air Conditioner | |||||||||||

Type | variable double–piston pump | |||||||||||||

Max. discharge flow | 455.5L/min | |||||||||||||

Max. discharge pressure | ||||||||||||||

Boom, arm and bucket | 32.3MPa | Control | Two hand levers and two foot pedals for travel Two hand levers for excavating and swing; Electric rotary-type engine throttle | |||||||||||

Travel circuit | 32.3MPa | |||||||||||||

Swing circuit | 25.5MPa | |||||||||||||

Control circuit | 3.5MPa | Boom, Arm & Bucket | ||||||||||||

Pilot control pump | Gear type | Boom cylinder | 120mm×85mm×1335mm | |||||||||||

Main control valve | Negative flow control | Arm cylinder | 135mm×95mm×1490mm | |||||||||||

Oil cooler | Air cooled type | Bucket cylinder | 115mm×80mm×1120mm | |||||||||||

Swing System | Refilling Capacities&lubrications | |||||||||||||

Swing motor | KAWASAKI, Japan | Fuel tank | 400L | |||||||||||

Swing motor type | Axial-piston motor | Cooling system | 14L | |||||||||||

Brake | Hydraulic oil released | Engine oil | 20.5L | |||||||||||

Parking brake | Hydraulic disc brake | Hydraulic oil tank | 200L Tank oil level | |||||||||||

Swing speed | 12r/min | 254L Hydraulic system | ||||||||||||

Bucket | ||||||||||||||

Type | Backhoe bucket | |||||||||||||

Bucket capacity | 1.0m3 (SAE) | |||||||||||||

Bucket width | 1150mm | |||||||||||||

Arm Type |

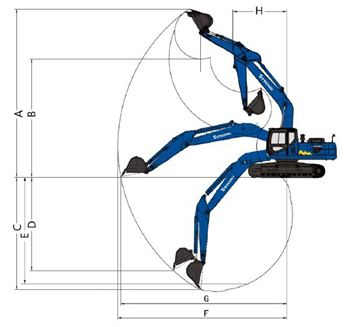

| |||||||||||||

A | Max. digging depth | 10080mm | ||||||||||||

B | Max. dumping height | 7079mm | ||||||||||||

C | Max. digging height | 6504mm | ||||||||||||

D | Max. vertical digging depth | 5910mm | ||||||||||||

E | Max. Depth cut for 2440m(8')Level Bottom | 6265mm | ||||||||||||

F | Max. digging distance | 9859mm | ||||||||||||

G | Max. digging radius at ground level | 9677mm | ||||||||||||

H | Min. swing radius of work equipment | 2972mm | ||||||||||||

Digging Force (ISO6015) Unit: kN | ||||||||||||||

Arm length | 2900mm | |||||||||||||

Bucket digging force | 127.7kN | |||||||||||||

Arm digging force | 120.4kN | |||||||||||||

Arm Type 2900mm | ||||||||||||||

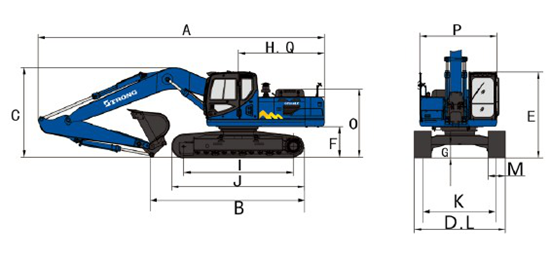

A | Overall length | 9512mm | I | Tread | 3655mm | |||||||||

B | Ground contact length (Transportation) | 5020mm | J | Track length | 4477mm | |||||||||

C | Overall height(to top of boom) | 2941mm | K | Track gauge | 2380mm | |||||||||

D | Overall width | 2980mm | L | Track width | 2980mm | |||||||||

E | Overall height(to top of cab) | 2998mm | M | Shoe width | 600mm | |||||||||

F | Counter weight ground clearance | 1063mm | O | Bonnet height | 2365mm | |||||||||

G | Ground clearance | 440mm | P | Revolving frame width | 2700mm | |||||||||

H | Tail swing radius | 2850mm | Q | Distance from swivel center to tail | 2813mm | |||||||||

| ||||||||||||||

Operating Weight and Ground Pressure | ||||||||||||||

Operating weight includes basic machine (with boom 5.7m, arm 2.925m, and bucket 1.0m3) | ||||||||||||||

Shoe width | 600mm | |||||||||||||

Overall width | 2980mm | |||||||||||||

Ground pressure | 43.8KPa | |||||||||||||

Operating weight | 21700kg | |||||||||||||

- Q:i have one male about three inches long and two femals two inches long (head to tail)

- That is hard indeed. i had a pair for 2 years and they never ever mated. Substrate: Try to use the excavator burrowing clay. This is fairly easy to keep clean and if given proper care you should only need to clean it every 6 months. Another on is reptibark or a mixture of dirt and sand 4:1 (without fertlizer). Lighting: You should use a 5.0 UVB light. Like Repti-Sun 5.0. Try to keep the theme rainforest-ish. Don't use heat rocks because it will burn their stomachs. If using a ten gallon cage I recommend using a 25 watt spotlight as it is very weak and won't burn your lizards while still giving them the heat they need. Branches and hides can be placed in the tank. They will climb branches and these are good for basking. They will need the basking side to be of about 90 degrees and a cool side of 75-80 degrees. Other: Misting the cage once a day will keep them at a good humidity. Also give them a water dish that is deep enough for them to soak in. For feeding you can offer them mealworms, crickets, roaches, waxworms. They do not eat any vegetable matter. Clean the cage every 2 weeks.

- Q:Can anyone tell me the Country 92.5 Country Club Drive Code for 2/29/08?

- the codes String is (just cut and paste in all): blajarlinbadturexc .

- Q:NEW ORLEANS - Thieves hauled off $100,000 worth of heavy equipment that was being used to help build a Lower Ninth Ward memorial to the victims of Hurricane Katrina. A Bobcat excavator and a Bobcat T300 Skid Steer Loader, both of which require trailers or flatbed trucks to transport, were removed from the site sometime between midnight and 6:30 a.m. Saturday, construction company officials said.In the neighborhood that remains nearly pitch black at night almost a year after the levees failed, the equipment didn't last three days at the site.Can you really blame them???? Almost a year and no fucin homes put up and some assholes are tryin to build a memorial for the dead people (no disrespect) and sayin fuc the ones that are alive, I would have stole the equipment too. Why the hell are they even building a memorial in a town where anyone that its quot;SUPPOSEDquot; to be for isnt even there to see it because they are out of a home and jobs, what the fucs the purpose????

- Yeah, I didn't see that in the TP and I read it every day. No real surprise, but I firmly believe that the Lower 9 has every chance at recovery as do other, less hard hit neighborhoods. Residents must return and must be a part of the recovery process. No exceptions, no waiting for handouts. This means rolling up your sleeves and cleaning up your house, your block, your neighborhood. Wanna blame Nagin? Try again! New Orleans has been broke and devoid of sound education, sound political processes for DECADES. Wanna wait for Entergy to swing by and turn on your power, maybe pour you some iced tea? Maybe Bellsouth will also come over and rip out your drywall? This city is overrun with a population that can no longer take care of themselves, and this is why it looks like it does after 12 months. Come drive down my street. I took 4 feet of water. My street looks good. Most everyone is back. I pick up the trash in the street. Neighbors made and hung street signs. I mow the neutral ground. That's how it works.

- Q:When Will the AMD Steamroller Be Released?

- I okorder .

- Q:What is the structure of the excavator?

- Thoroughly inspect the surroundings and bottom of the locomotive in accordance with the following sequence: 1, whether there is oil, fuel and coolant leakage. 2, whether there are loose bolts and nuts?. 3 、 is there any broken wire, short circuit and loose joint of the battery in the electrical circuit?. 4, whether there is oil pollution?. 5, if there are rumors accumulation. Daily maintenance notice of daily inspection work is to ensure that the hydraulic excavator can be an important part in maintaining long-term efficient operation, especially for the self-employed, do the usual daily inspection work can reduce maintenance costs. First of all, around two laps to check the appearance of mechanical and mechanical chassis or unusual, and whether there is a rotary bearing oil flows out, and then check the braking device and bolt fastener track, tighten the screw, the change of the change in time, if you need to check the tire wheel excavator is whether there is abnormal, and pressure stability. Excavator bucket teeth to see whether there is greater wear, it is understood that the bucket teeth will greatly increase the wear and tear in the construction process of resistance, will seriously affect the work efficiency and increase the wear and tear of equipment parts. See if there is crack or oil leakage in the bucket and the cylinder. Check battery electrolyte to avoid below level line. The air filter is an important part of preventing dust from entering the excavator. It should be checked and cleaned frequently. Always check the fuel, lubricating oil, hydraulic oil, coolant, etc. whether to add or not, and choose the oil according to the requirements of the manual, and keep it clean. After starting check 1, whistle and all instruments are in good condition. 2, engine starting state, noise and exhaust color. 3 、 is there any leakage of oil, fuel and coolant?.

- Q:I don't see what the difference is between the two of them.

- A backhoe is usually mounted on the back of a rubber tired tractor while a trackhoe is mounted on a caterpillar-style tractor -- or is manufactured as a stand-alone track-mounted vehicle.

- Q:What did Baby Jesus' birth certificate list under father's name and father's occupation?

- do you think they actually had birth certificates back then

- Q:How to change tracks on bobcat excavator 435?

- Not sure on this model but track are tensioned using grease that is injected in a cylinder that's pushing on the front idler. Remove the grease zerk and you will need to compress the cylinder to loosen the tracks. There's a couple ways this could be done. One push them in with another piece of equipment or use the boom and push them in. The other way is use a 2 X 4 or 4 X 4 and insert it between the tracks and front idler wheel and run the tracks very slow this will compress the cylinder. Now you will need to find the main link it they are steel track or just pull the track off after you have rotated the boom around to that side and pushed down on the ground with it to raise the track off the ground. After installing the new track replace the grease zerk and fill with grease till you get the correct tent ion on the track.

- Q:When was Troy founded, and by who?

- The first city of Troy was founded in 3,000 BCE. Ilus, the son of Tros is the founder of Troy according to legend. Ilus (Ilos in Greek) is in Greek mythology the founder of the city called Ilion (latinized as Ilium) to which he gave his name. When the latter became the chief city of the Trojan people it was also often called Troy, the name by which it is best known today. Ilus was son and heir to Tros of Dardania and brother of Assaracus and Ganymede. He won the wrestling prize at games held by the King of Phrygia and received fifty youths and maidens as his reward. The king also, on the advice of an oracle, gave him a cow and asked him to found a city where it should lie down. Ilus did so. Ilus then prayed to Zeus for a sign and at once saw the Palladium fallen from heaven and lying before his tent but was immediately blinded for the impiety of looking on the image. He regained his sight after making offerings to Athena. Ilus preferred his new city of Ilium to Dardania and on his father's death he remained there, bestowing the rule of Dardania on his brother Assaracus instead and so the Trojans were split into two kingdoms.

- Q:Sometimes long term, some times short term - per job basis. How do the dr. and cr.? I can see it being both a COGS and an expense account. What is the proper method and how would my journal entries work?

- If the equipment is used directly in the construction side of the project, e.g. excavators, then the equipment is a direct cost and I would include it under COGS. If the equipment is like an overhead projector you use when you make a sales pitch before you got the contract, that would be a selling expense. Dr Equipment rental expense xxx Cr Cash or accounts payable xxx

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GC228LC-8 Hydraulic Crawler Excavator

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 40 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords