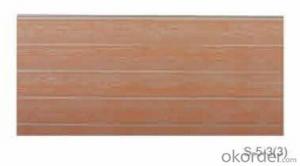

Fiber Cement board for villas,high building-013

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: The tile guy that I am using has never worked with stone, so I am worried. Can you please give me some insight on some things I should know about using stone (slate) for wall tile in a shower/bath.

- I have to ask is the Slate Milled, or like field stone. 1/2 inch concrete backer board on studs is sufficient. I'd also use a vapor barrier, perhaps even double wall backer board. Vertical installs shouldn't be attempted by someone unfamiliar with the tile species, but I have to assume theyd' like to learn, at least. As an installer he should know the properties of various mortars and mastics used for many species of wall tile, and perhaps apply those to slate, unless it isn't milled. Then it would be more like building a stone facade on a structure. Certainly slate would be more porous, since it's likely unglazed, but glazing it yourself will probably turn into a life long career in maintaining. If this happens to be SLATE in the form of tile, install and grouting will be much easier. If this is to be a more rustic effect, with mosaic shapes in some rough slate, I'd make sure the installer had some better level of knowledge. Steven Wolf Just my 2 sense

- Q: how do you join cement board from a shower wall to drywall?

- Other than being nailed to the same stud, it is not all that necessary that they be joined together. Just figure on the tile overlapping the drywall about a half an inch to kill the crack. You can mesh tape them together however and skim them flat with each other as long as you don't skim wide into the tile board area. You could do as little as just caulk the crack with silicone too.

- Q: Is it ok to pour floor leveling compound over hardibacker cement board?

- Yes, just make sure you've used a lot of screws to hold the backer board down or your compound will crack to pieces if the board moves at all.

- Q: I am planning on replacing my current bathroom floor with 3/4 plywood. I want to use 1/4 cement board as my sub-floor. However, I am not sure if peel and stick flooring will work with cement board. Please help.

- First of all, you sub-floor is the 3/4 plywood. Anything over that is overlayment. What goes over that is the flooring. I agree with the 1/4 luan. What I don't agree with is why in the world would anyone use peel and stick flooring.

- Q: I am in the process of purchasing a townhome and I am looking to tear up the existing 12 ceramic tile that covers the entire main level... an area close to 600 sq. ft. to make way for laminate flooring. Thinset has been used to bond the tile to the cement backer board, and the backer board has been screwed to the wooden subfloor. There is also some sort of adhesive/mortar bonding the cement board to the wooden subfloor. What tools will I need. Are there any techniques that would make it easier? Would trying to remove the cement board damage the subfloor? If so, would it be acceptable to repair damage with some sort of floor leveling compound?

- big *** crow bar, thats how i did my kitchen, yep it sucks. you can get a nice one for this in the garden section its made for digging holes but has a nice flat section, for what I dont know but it teats a floor up,

- Q: Can v board be glued directly on the wall?

- Downside, will be installed on the four sides of the UV board with a chamfering machine down to 45 degrees angle. According to the actual installation requirements, and some just down the next two sides or three sides.

- Q: Application of cement pressure plate

- Cement pressure plate can be used for LOFT steel structure sandwich, movable room wall floor and so on.

- Q: i glued a piece of regular printer paper to a piece of matboard as part of an art project. since i applied rubber cement to both the paper and the board, it bonded quite strongly. the problem is that now i have to remove the paper with the least amount of damage to the matboard. the paper is white and the board is black. its been over a week since i glued the two together. HELP!! i need this for school and it has to look good...any suggestions??im going to throw the paper away, so that can be damaged in the process. no problem.

- Try pulling the paper off...and use your hand to ball up the rubber cement

- Q: What do I need when I put my toilet back down so it won't leak now that my toilet is 3/4 of an inch higher?

- You'll need a riser piece to add to the drain. Or you could just build the tile up around the toilet and re caulk.

- Q: What are the densities of tiles and cement

- In the production and processing process, wood in the wood board of wood components through non-toxic chemical mineralization after the fire produced. These treated mineralized wood components combine with the Portland cement base to increase its strength and toughness, resulting in significant structural features and excellent quality of Portland cement: fire, moisture, Corrosion, pest control, and durability. The overall structure of the wood fiber board makes it resistant to impact and easy to process. Due to the close structure, high density, wood fiber reinforced concrete board sound insulation is excellent, and affordable,

Send your message to us

Fiber Cement board for villas,high building-013

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords