Fiber Cement board for villas,high building-003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

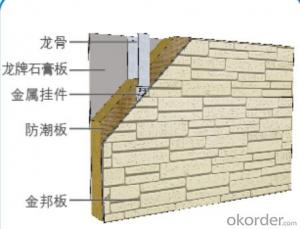

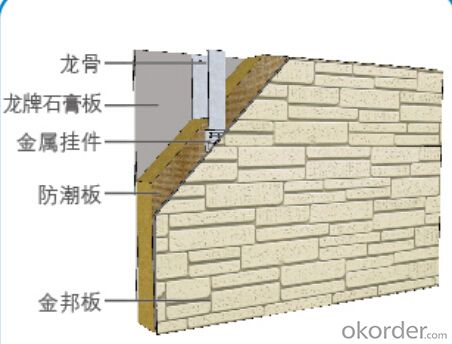

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: i have ready mix cement that you just add water to & i want to make my own bricks.what is the easiest way to make a mold.thanks for any help

- Just stack the bags of cement on top of each other, wet them down, they will harden where they lay.

- Q: Can v board be glued directly on the wall?

- Downside, will be installed on the four sides of the UV board with a chamfering machine down to 45 degrees angle. According to the actual installation requirements, and some just down the next two sides or three sides.

- Q: Can someone tell me if they know or what they would think is stronger, six cement blocks stacked high or a board that is 6 feet long and 6 by 6?

- are the cement blocks stacked without mortar? are the cement blocks loaded in bending or compression? is the board loaded in bending or compression? What is the criterion of failure? cracking or breaking? Not a fair comparison with out some explanation.

- Q: do i have to use cement board under tile on a shower wall?

- Cement board, Denshield, or Hardibacker board , all with a vapor barrier behind it is the best and longest lasting products to use. DO NOT use green sheet rock, especially if its a straight stand up shower. IT WILL NOT LAST.. In a tub/shower, I ve found that the average green board lasts about 7 years at best in a well used shower. There is also a product called Detra that can be used in a shower but I personally have never used it. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: What besides cement board can i use to set tile on?

- Just 2 other options to properly do tile. That is a mud base, but thats not for the average DIY. Or you can do a wood sub floor over your current wood sub floor.Several precautions if you do a wood base. It must be 3 ply fir , you must adhere it and nail it ( or screws) in a certain way. This if your going over the standard 3/4 standard sub floor. You must use at least a 1/2 ply wood. When done right a wood sub floor is almost ( almost) as good as a cement board base. But I d do cement board over a wood base any day. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Clothes on the stick asbestos fiber how to do

- It is ok to stick with the tape can be used to wash clothes just fine. Wipe with a sponge

- Q: How durable and lasting is the concrete board that is installed on homes? IS it true that it doesn;t need painted for at least 15 years?Thank you

- it can last even longer depending on exposer to weather, feild painted or factory painted. hardi plank or certinteed cement board are both good products. the main thing is to keep the back side of the board ( keep n eye on your caullking ) if moisture can wick threw the board , the paint will start to fail and peel.

- Q: what does this mean second phase in two phases material ( first phase is binding cement ) ?

- First consider the term 'phase' as in 'phase change', such as ice melting. It means a particular state of matter, solid or liquid in the melting of ice. However, in an inhomogenous solid material you can have two or more solid phases. For instance, Transite insulation board was made of portland cement and asbestos [not in use much nowadays]. So what you have is some two phase inhomogenous solid consisting of one phase as binder or cement, and the other phase could be a filler, a fiber, or whatever.

- Q: I want a smoother cut than I will get by scoring and breaking. Would I use an abrasive wheel in a circular saw or a diamond blade?

- a diamond blade is good yes, but running it perfectly straight is the difficult part. Make your self a straight edge so your saw or angle grinder can rest against it as your cutting ( say the blade is 50mm from the saw base or angle grinder guard, put your straight edge 50mm away from your line) when it is cut get a piece of cement board and rub it along your cut to achieve a factory finish you could also buy a cement board blad ( it has only 4 teeth and it can fit onto your circular saw,) other then that you can use an angle grinder with a diamond blade.

Send your message to us

Fiber Cement board for villas,high building-003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords