Fiber Cement board for villas,high building-008

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

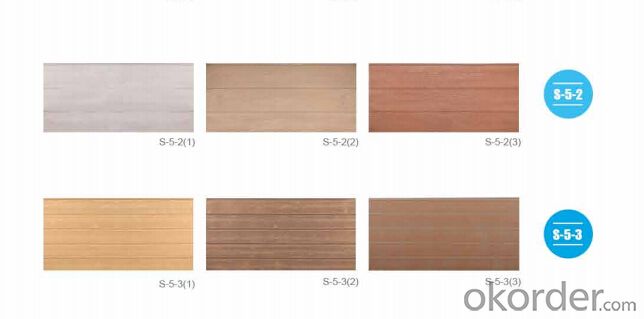

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

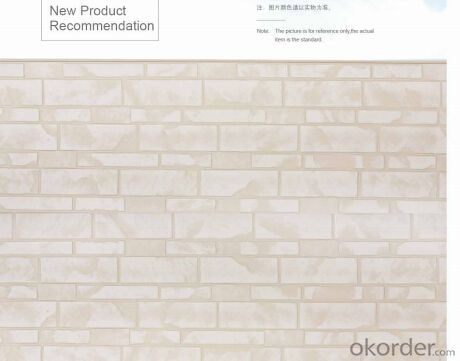

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: Do I have to put cement backer board down before laying ceramic tile or can I go over existing vinyl floor?

- I would worry more about whats under the vinyl. If the subfloor is just 1/2 plywood, it will move up and down when walked on. It may not be measurable with the vinyl but it will with hard ceramic tile. Your tiles and grout will crack. Most ceramic tiles require at least a 3/4 subfloor. Ceramic adhesion will not be good either over vinyl.

- Q: I'm putting in a new tub surround this weekend (gutting the bathroom wall and starting from scratch). After I put cement board on the studs and install the tub surround, there will be a space about foot high between the surround and the ceiling. The cement board will be exposed. Can I paint the cement board so it matches the colors of the bathroom? Do I need to buy special paint or something? Obviously, I've never done this sort of thing before and I appreciate any advice I can get.

- You may want to run the concrete backer only about 3' up that will cover the real wet part of the tub surround then just use the green sheet rock on the top. Tape and float it put the surround up then texture and paint. Use semi gloss paint all over your restroom area with a added mildew inhibitor even if the paint is mildew resistant. Just tell them you don't care you want to add it anyway.

- Q: Can you put ceramic tile over wood floors? If yes I was told that it wouldnt stay, even with cement board.?

- Without reading any answers here, and after installing thousands of sq. ft. of flooring,,,especially tile. I suggest that EVEN on a concrete slab,,, perfection isn't something set in stone,,, so to speak. You don't state the state of the construction,,, IE: Basement or crawl space below the existing floor, slab on dirt, etc.. ANY floor substrate should be as level as you can get it,,, but even that can be supplemented by leveling a tile installation. Concrete backer board is my choice, no matter the substrate, as it allows for less movement, degradation over time, a porous/textured enough surface to GRAB thin set, with less chance for warp,,, as long as the bottom line is as secure as possible. Perhaps your least or greatest concern might be removing any existing base molding and determining adding what might be near 3/4 inch height to existing flooring. Consider a deeper issue. This is EARTH, on top of which,,, or in which a house has been built. I suggest no stronger force exists than that of the EARTH.... and it gives and takes, in its process. Consider too, the prep work, and knowledge of the structure, its construction, and history. Does it tend to ebb and flow like Tides? Or has its base element been relatively secure since it was constructed? Then consider that it may last longer, no matter what you do, or what was done, than your lifetime,,, No offense. It would seem that research is your first exploration option, and valid experience. If in fact the base flooring is above a basement or crawl space some shimming might be called for, especially if the existing floor seems to squeak, or be pliant. If it's Concrete, I suggest you don't stress. E mail accepted for more info. Rev. Steven

- Q: Directly on the cement board to brush the glass can you!

- Yes, but before the brush to re-clean the cement, can not have dust, or paint easy to fade.

- Q: Can you hang outside garden wall hangings on fiber cement board siding and what is the best way to do it?

- Yes okorder / Now if youre talking about regular concrete lap siding then I have used a sheetrock screw to hang trim before and it worked fine. Its a little hard to get started so dont push hard as you may damaged the siding but once they anchor they hold great.

- Q: I'm having old (30 plus years), damaged slate tiles removed and replacing it with ceramic tiles. I've discovered there is cement underlayment under the slate tiles. I'm having this work done for me and so far the floor looks like grenades have hit it. There are pot holes. How in the world are you suppose to remove these slates tiles that have been adhered to cement?? And, how do you repair the flooring to eventually lay down cement board and ceramic tiles?? I'm sick to my stomach.

- As long as the cement is intact and not cracked, you can set the new tile right over it. Just knock off any high spots that are left after getting up the old tile, then trowel on new thinset mortar using a 3/8x1/4 square-notched trowel. As long as the existing cement is sound you do not need to remove it; this is an ideal base for new mortar. If it is cracked, this means that the plywood underlayment is moving up and down because it was not secured properly to the floor joists. But if the cement is in good shape there is no need to remove it. (Usually jobs that were done by craftsmen years ago who knew what they were doing are better than anything you can get today; you would not want to rip out a perfectly good base and replace it with something substandard.) As a matter of fact, if the existing tile floor has no loose tiles and no cracks, you really don't even have to remove it if you can go with the additional 1/2 or so in height that a new tile floor would entail. Just mortar right over it.

- Q: What is the cement pressure plate?

- Cement pressure plate, also known as fiber cement pressure plate or cement fiber pressure plate, is a natural fiber and cement as raw material, by the pulp, forming, cutting, pressing, curing a new type of building plate. Is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features. It is based on siliceous and calcareous materials as the main substrate, with cellulose fiber reinforced materials, mixed with other auxiliary materials, through the copy forming, high pressure curing the formation of a new type of building materials. With light, high strength, waterproof, anti-corrosion, fire, large format, good processing, improve construction efficiency and so on. Widely used in civil and industrial buildings. Can be used for building floor, interior wall panels, exterior panels, ceiling panels, curtain wall panels, composite wall panels, insulation materials, roofing and other parts.

- Q: Replacing the cement board is not realistic, I don't know of anything that may be more flexible and not deteriorate so quickly.

- there are some colored cement repair products that contain silicone that may work good, also you can just use white silicone or caulk just squeeze it in and let it dry have a rag handy for cleanup both are flexible and last a long time.

- Q: can a double drywall wall be replaced with cement board or backer board?

- One layer can be replaced with a cement board and still be fire rated in most all areas. Using just one layer you can still be flush and use an SBN (surface bull nose) to trim it out. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: This is a 1950s sink.

- I assume that you mean the tiles are attached to the counter-top. The process is called demolition, and it can get dusty. Safety glasses are a must, a dust mask is recommended. First, starting at the back-splash, slice any caulk at the seams where the tile joins the wall with a sharp knife. Then, crack the tiles, enough to get a pry-bar under them. Peel, pry or knock the tiles off, exposing the plywood or cement board underneath. If you can find screws or nails attaching the back-splash to the wall, remove them. Then, look underneath the counter for screw or nails which attach the cabinet to the wall, remove them. At this point, you can try prying the whole structure away from the wall(s). Be careful about pry-bar placement. You should only pry where there is a stud on the inside of the wall, typically every 16. If it doesn't budge, look for any fasteners you missed. NB- Before you start, turn off the water, disconnect all the plumbing, cover the drain pipe (to keep debris out of it and sewer gas inside it. A drop-cloth would help in the cleanup. expect to spend some time patching the wall when you're done. Good Luck

Send your message to us

Fiber Cement board for villas,high building-008

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords