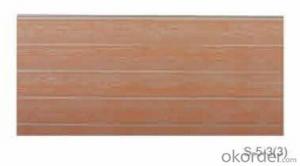

Fiber Cement board for villas,high building-015

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: I am building a shower in the basement of a 50 year old house in Michigan. I am using cement board (backerboard) for the sides which I framed in. The back of the shower is the existing cement block wall. Can I apply the mortar and tile to the cement block wall just as I would for the cement board? Will there be any problems with it stinking? The wall will get chilly during the winter.

- Sure ! As long as the wall is clean. lf using big tiles 6'' square or bigger, buy a bag of spacers.$3. Big tiles will creep down towards the bottom of the wall from thier weight. Stand back and check them. Good luck !

- Q: Plywood, gypsum board, cement board, aluminum-plastic board, which to choose, why?

- Cement board, plywood can do partition, gypsum board, plywood can do ceiling. Aluminum-plastic panels are only decorated with the surface, both can be. Cement board strength is good, but the weight is large, suitable for partition board; gypsum board has several kinds, there are partitions with a plate with a ceiling. There are several plywood, the general 3 to 5 plywood can do decorative panels of the grassroots, there are thick plywood can be used to do partition.

- Q: I've removed the old cement boards and I've put new ones up on the shower walls. My tile will not go to the ceiling. I'm at the step where I need to apply thin-set and tape to all of the cement board seems. What do I do at the seem that transitions from cement board to sheet rock?

- yes, and make sure that walls are Straight and LEVEL, or you will not be happy with results.

- Q: I'm laying slate tile over linoleum that was installed about 6 months ago....the linoleum is in very good condition, very smooth with no rips or lifting. I've done some research and figured I could put down cement board and then lay the tile on that. The floor under the linoleum is cement. Is there a special drill/special screw necessary to attach the cement board to the cement foundation?

- You would be a lot better off removing the linoleum. You wouldn't need the expense/hassle of installing cement board, since you would be tiling directly on concrete. If you really don't want to do that, you will need to use a hammer drill and Tapcons. Use 3/16 x 1-3/4 screws. with a 5/32 masonry bit. Remember that you are adding height to the floor as well, and will need to make transitions to other surfaces. If there are any doors that open into the kitchen, they may need to be cut. Hope this helps.

- Q: What kind of mortar do you use to tape joints in cement backer board?

- thin set. the same mortar you use to set the tiles with.

- Q: The difference between cement fiberboard and cement pressure plate

- Fibreboard' name emphasizes the reinforced material 'fiber'; 'pressure plate' name emphasizes the production process, the use of presses on the board green pressure, squeeze out the water and compaction, improve the board density and strength. 'Cement fiber board 'Is a more traditional name, but in recent years is also known as' cement pressure board'.

- Q: The reason I ask is b/c my boyfriend was supposed to tile the kitchen..he put down the cement board for it and assured me we bought enough clearance tile. I was unsure and measured, we don't. He has procrastinated and I don't know how to tile anyways, so I want to lay a different floor. BUT I don't want to just throw away this cement board(might learn to tile one day). Is there a type of flooring that could easily just be installed over top of the cement board?

- Make sure the disk isn't upside down, It happened to me one time and I just totally facepalmed

- Q: Is it okay to install ceramic tile on greenboard, or is cement board necessary?

- Bigg_dogg44 is correct on the question above. Also in addition if you are going to set tiles use versa bond flex white as it has a better bond. do not use mastic for wet areas

- Q: I'm getting my bathroom shower tile installed and was told to get 4 sheets 1/2 thick backerboard with screws and I need to know if there is a difference between Cement Board and Backer Board?

- Same thing. Backer board is a general term. Backer board can be 1/4 thick. can be a wood substrate used for tile is certain circumstances ( not yours), it can be the Hardi board which is a cementrous type board. Basically a backer board any thing that goes under any tile . You should get the cement board for your application. And if your doing a shower and he/she didn t suggest it, a vapor barrier is also needed under the cement board.in the shower area. Any questions you e mail me through my avatar and check my qualifications there. GL

- Q: Is a vapor barrier needed behind cement board in a shower?

- Vapor barrier isn't needed in a shower unless it's on an exterior wall. The concrete board is enough for interior walls. Good Luck

Send your message to us

Fiber Cement board for villas,high building-015

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords